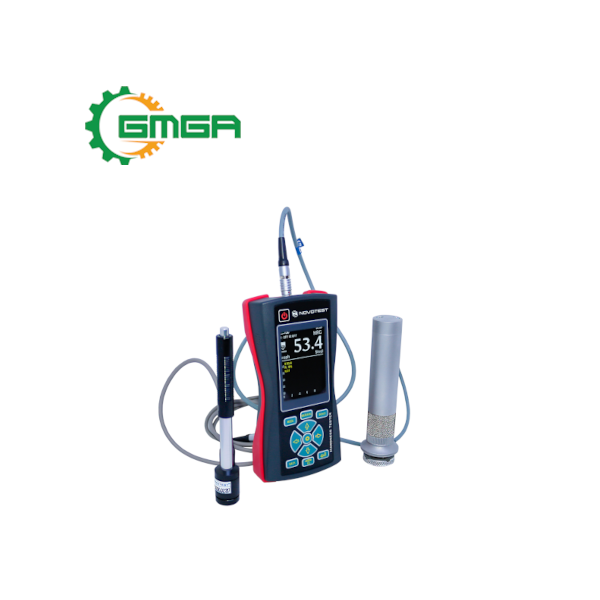

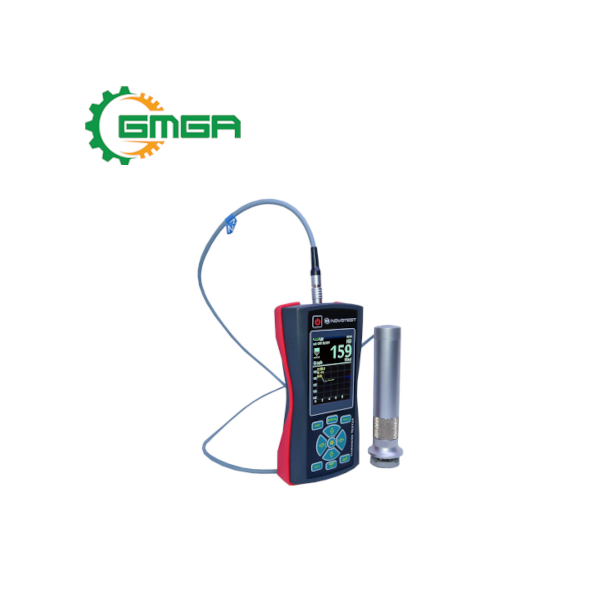

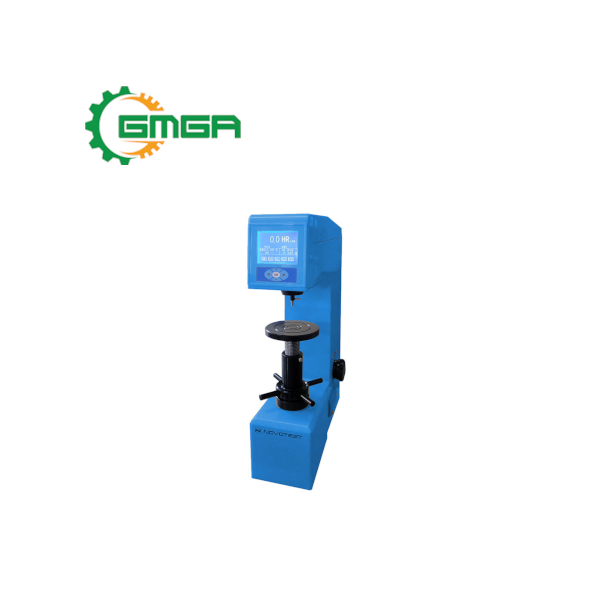

Hardness tester NOVOTEST TB-BRV Brinell, Rockwell, Vickers

Price: Liên hệ

| Model | TB-BRV |

| Manufacturer | NOVOTEST |

| Power supply | |

| Weight | |

| Size | |

| Condition | Còn hàng |

| Warranty | 12 tháng |

I. Specifications of the versatile Hardness tester NOVOTEST TB-BRV

- Analog Brinell, Rockwell, Vickers hardness tester NOVOTEST TB-BRV is designed as universal, it can be used in industry, scientific research laboratories, factories and workshops, etc.

- The NOVOTEST TB-BRV Brinell, Rockwell, Vickers hardness tester features a new design and offers high usability and high reproducibility of results and is also very easy in operation.

- This versatile hardness tester uses multi-stage test loads and different types of probes to measure and determine the hardness value of products tested on different scales: Brinell, Rockwell and Vickers.

- The TB-BRV durometer is supplied with a special table that allows the user to measure the diameter of the imprint without sampling. The hardness tester has a special holder for the microscope, which greatly simplifies the operation of the instrument.

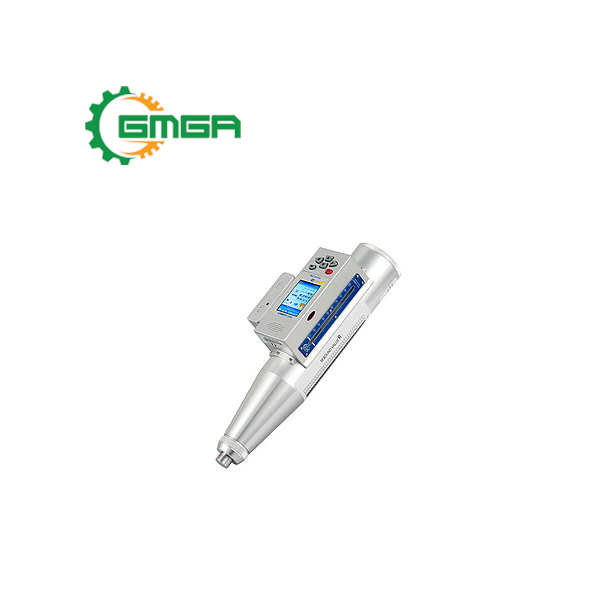

- Equipment with electric actuator - fully automatic main test load.

- The durometer provides high sensitivity and accuracy of the load level and high accuracy of the measured values. The machine has a built-in high-precision microscope with backlight.

- The testing application with different methods allows the user to solve almost all durometer tasks: measuring the hardness of different materials and over a wide range - from very soft to very soft materials stiffest.

- Brinell, Rockwell, Vickers hardness tester NOVOTEST TB-BRV performs Brinell, Rockwell and Vickers direct hardness testing methods according to ISO 6508 , ASTM E10 , ASTM E92 , ASTM E18.

II. Advantages

- The device is easy to operate and maintain

- Multifunctional hardness tester. Users can measure hardness in different scales (methods) and have no problem with hardness measurement over a wide range - from very soft materials to some of the hardest materials

- The special movable table allows the user to measure the diameter of the print without removing the sample from the device Special holder for the microscope, which greatly simplifies the operation of the instrument

- Built-in high-precision microscope with backlight

- Electric actuator - fully automatic main test load

- Allows the user to maximize the efficiency of using the handheld hardness tester. Using this device, the user can validate standard hardness test blocks and calibrate the portable hardness tester to any of the most common hardness scales.

III. Application

- This versatile Analog durometer allows users to perform:

- Hardness test of non-ferrous metals (steel, cast iron, low carbon steel and tempered steel, etc.)

- Hardness test of non-ferrous metals (alloys from aluminum, copper, etc.)

- Hard alloy hardness test, carburizing grade and chemical treatment.

IV. Standard package

- NOVOTEST TB-BRV . hardness tester

- Rockwell indenter (Conical Diamond Tool (120°)

- Vickers indenter (Four-sided diamond pyramid (136°)

- Brinell indenter (hard alloy steel ball 1.5875, 2.5, 5 mm diameter - 3 total)

- Weight (5 pieces)

- Large test board

- Average test table

- V-shaped lab table

- Migration test platform

- Rockwell hardness test block (HRC - 2 pcs, HRB - 1 pcs. - Total 3 pcs)

- Brinell hardness test block (1 pc.)

- Vickers hardness test block (1 pc.)

- Bolt adjuster (4 pcs.)

- Power cable

- Fuse (2 pcs.)

- Operating manual

- Certificate of Calibration

- Shipping Box.

V. Specifications of Brinell, Rockwell, Vickers hardness tester NOVOTEST TB-BRV

|

Indenter |

Rockwell: Conical diamond indenter (120 °) – diamond tip as a cone with 120 degrees of the cone apex angle and the bead size of 1/16 inch (1.5875 mm) |

|

Brinell: Hard alloy steel ball with a diameter of 1.5875, 2.5, 5 mm |

|

|

Vickers: four-sided diamond pyramid (136 °) |

|

| Scales |

Rockwell: HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK |

|

Brinell: HBW2.5/31.25, HBW2.5/62.5, HBW5/62.5, HBW2.5/187.5 |

|

|

Vickers: HV30, HV100 |

|

|

Initial load |

98.07N (10Kg) |

|

Tolerance: ± 2.0% |

|

| Testing load |

Rockwell: 60kgf (588N), 100kgf (980N), 150kgf (1471N) |

|

Tolerance: ± 1.0% |

Brinell: 31.25kgf (306.5N), 62.5kgf (612.9N), 187.5kgf (1839N) |

|

Vickers: 30kgf (294.2N), 100kgf (980.7N) |

|

|

Measuring time |

5~60 sec |

| Testing materials |

Ferrous metals (steel, cast iron, low carbon steel and tempered steel, etc) |

|

Non-ferrous metals (alloys from aluminum, copper and its alloys, etc) |

|

|

Hard alloys, carbonized and chemically treated layers |

|

|

Hardness range |

Rockwell: (20-88) HRA, (20-100)HRB, (20-70)HRC |

|

Brinell: (8-650) HB |

|

|

Vickers: (14-3000) HV |

|

| Max height of test sample |

Rockwell indenter – 170 mm (can be produced up to 400 mm) |

|

Brinell – 140 mm (can be produced up to 370 mm) |

|

|

Vickers – 140 mm (can be produced up to 370 mm) |

|

|

Max depth of test sample |

165 mm |

| Microscope zoom |

15X |

|

Lense zoom |

2.5X, 5X |

| Data output |

Rockwell – dial indicator |

|

Brinell – measuring microscope |

|

|

Vickers – measuring microscope |

|

|

Recommended operating conditions |

Air temperature: 0…+40 °С |

|

Air pressure: 94 – 106.7 kPa |

|

|

Humidity: up to 65% |

|

| Net weight |

60 kg |

|

Gross weight |

75 kg |

| Package dimensions |

630*500*860 mm (L*W*H) |

No comments yet

SIGN UP FOR A CONSULTATION

Please fill in the form below and send your comments and questions to GMGA, we will respond to your email as soon as possible.

COMMIT

100% new product

COMMIT

100% refund if the product is of bad quality and not as promised

DELIVERY

Nationwide

Review Hardness tester NOVOTEST TB-BRV Brinell, Rockwell, Vickers

There are no reviews yet.