Home » Products » Measuring Equipment » Hardness measuring equipment » Handheld hardness tester » UCI hardness tester PCE-5000

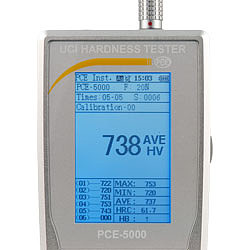

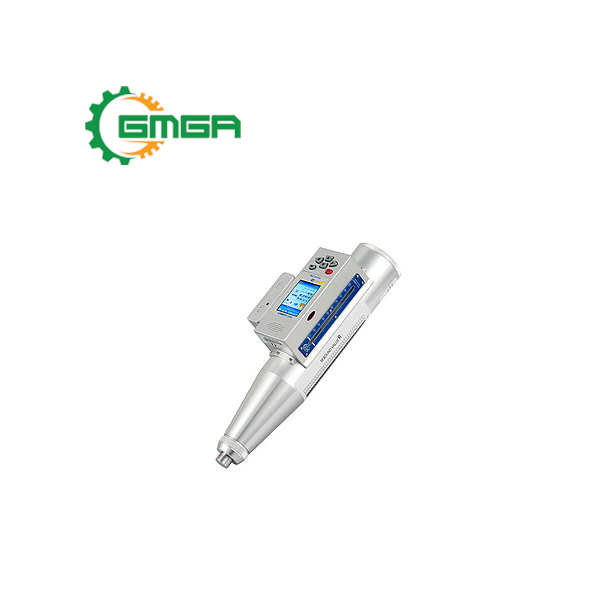

UCI hardness tester PCE-5000

Price: Liên hệ

| Model | PCE-5000 |

| Manufacturer | PCE |

| Power supply | |

| Weight | |

| Size | |

| Condition | Còn hàng |

| Warranty | 12 tháng |

I. Specification of UCI hardness tester PCE-5000

Hardness Tester - Handheld Hardness Meter PCE-5000 UCI Uses ASTM A1038 Ultrasonic Contact Impedance (UCI) method to test the hardness of metals and alloys.

- The PCE-5000 Gauge is a handheld hardness tester that uses ASTM A1038's ultrasonic contact impedance (UCI) method to measure the hardness of metals and alloys with a minimum thickness of 2 mm / .08 print.

- The ultrasonic hardness test of PCE-5000 is considered non-destructive, as it creates a microscopic indentation that can only be seen when using a high-powered microscope.

- With a fast measurement time of just 2 seconds, this UCI hardness tester is the ideal tool for testing welds, controlling the hardness of metal coatings and measuring the hardness of fine grained metals and small forgings. , casting materials, heat-affected zones, die ion stamping and dies, forms, presses, thin-walled structures and parts, bearings, tooth flanks, tubes, tanks, steel plates and products have a complex or complex shape.

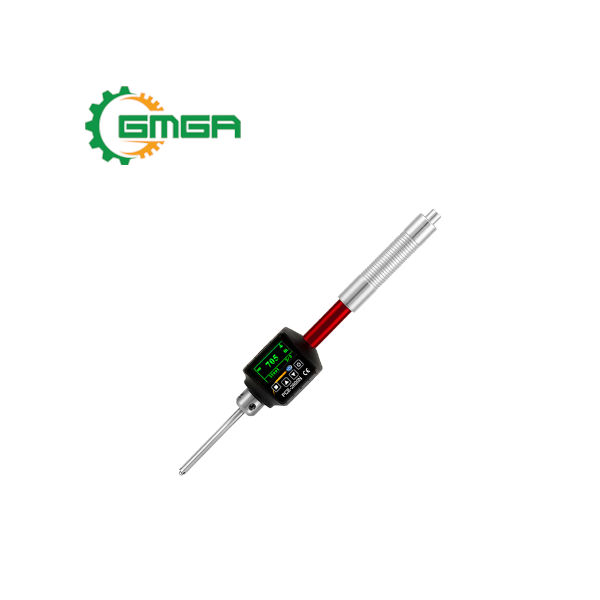

- The additional measuring sensors of this versatile durometer can be directly connected to the ultrasonic tester, they vary in test force and are applicable to durometer hardness testing requirements. difference.

- Different sensors measure the hardness of objects depending on the roughness of their surface. For example, a standard sensor with 20 N measures surfaces with a roughness less than 5 µm. The 10 N sensor measures roughness less than 3.2 m and the 98 N sensor measures roughness less than 15 m.

II. Advantages

- Hardness measurement of metals and alloys with a minimum thickness of 2 mm

- Displays measurements in Rockwell A (HRA), Rockwell B (HRB), Rockwell C (HRC), Brinell (HB), Vickers (HV) and MPa (N/mm²) SI units

- Measuring range: 61 … 85.6 HRA, 41 … 100 HRB, 20.3 … 68 HRC, 85 … 650 HB, 50 … 999 HV, 255 … 2180 MPa (N/mm²)

- Accuracy: ±1.5 HR, ±3% HB, ±3% HV

- Store up to 2000 measurement groups / 20 calibrators in memory

- Provides measurements in just 2 seconds

- The probe fits into small spaces and hard to reach places

- Features large and easy-to-access LCD readout, simple calibration and RS-232 interface.

III. Standard package

- 1 x PCE-5000 UCI hardness tester with 1 x 4.2V battery

- 1 x 20 N probe (standard)

- 1 x Protective cap for probe (silicon)

- 1 x Probe cable

- 1 x USB cable

- 1 x USB charger

- 1 x RS-232 interface cable

- 1 x Screwdriver

- 1 x Vibration-resistant carrying case

- 1 x User manual

IV. Specifications of UCI hardness tester PCE-5000

|

Measuring range |

|

| Rockwell A B C |

61 … 85.6 HRA, 41 … 100 HRB, 20.3 … 68 HRC |

|

Brinell |

85 … 650 HB |

| Vickers |

50 … 999 HV |

|

Tensile strength |

255 … 2180 N/mm² |

|

Accuracy |

|

|

Rockwell |

± 1.5 HR |

| Brinell |

± 3% HB |

|

Vickers |

± 3% HV |

|

General specifications |

|

|

Measurement method |

Ultrasonic contact impedance (UCI) per ASTM A1038 |

| Direction of measurement |

360° |

|

Measurement time |

2 seconds |

| Hardness units |

HRA, HRB, HRC, HB, HV, MPa |

|

Display |

LCD with backlight |

| Minimum material thickness |

2 mm |

|

Data memory |

Up to 2000 measurement groups |

|

Up to 20 calibration sets |

|

|

Measurement probe |

20 N (standard) |

| Probe cable length |

1.5 m / .06 in |

|

Functions |

Single value, min / max, average value |

| Power supply |

4.2V rechargeable battery, 4800-mAh |

|

Battery life |

Approx. 10 hrs of operation at full charge (without backlight) |

| Dimensions |

162 x 81 x 31 mm / 6.38 x 3.19 x 1.22 in |

|

Operating conditions |

-10 ... 40°C / 14 ... 104°F, ≤ 85% RH |

| Storage conditions |

-20 ... 60°C / -4 ... 140°F, ≤ 85% RH |

|

Weight |

Approx. 755 g / 1.67 lb (including probe) |

No comments yet

SIGN UP FOR A CONSULTATION

Please fill in the form below and send your comments and questions to GMGA, we will respond to your email as soon as possible.

COMMIT

100% new product

COMMIT

100% refund if the product is of bad quality and not as promised

DELIVERY

Nationwide

Review UCI hardness tester PCE-5000

There are no reviews yet.