Home » Products » Measuring Equipment » Hardness measuring equipment » Handheld hardness tester » Universal hardness tester PCE-3000UL

Universal hardness tester PCE-3000UL

Price: Liên hệ

| Model | PCE-3000UL |

| Manufacturer | PCE |

| Power supply | |

| Weight | |

| Size | |

| Condition | Còn hàng |

| Warranty | 12 tháng |

I. Specification PCE-3000UL universal hardness tester

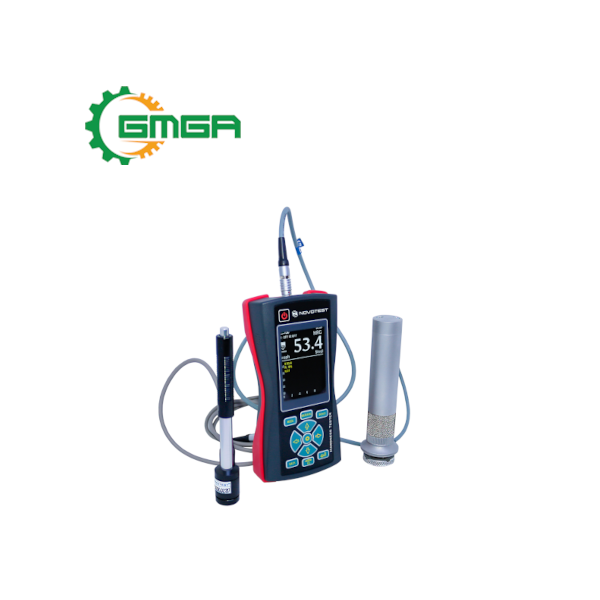

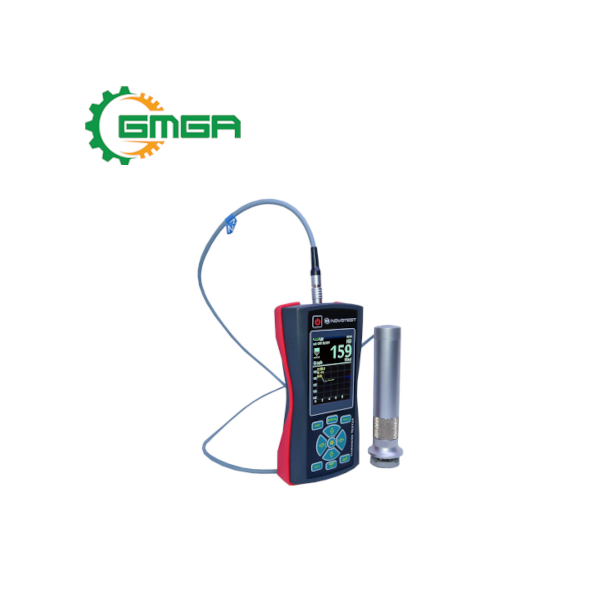

Multifunction UCI Hardness Tester - Leeb PCE-3000 series Portable UCI Hardness / Hardness Tester HRC, HB and HV / NDT Instrument for Proper Rm Tensile Measurement / For 1mm Thickness Parts.

- The UCI PCE-3000 Universal Handheld Hardness Tester can be used to quickly test the hardness of parts even after installation.

- This instrument offers a wide measuring range, easy handling, robust design and temperature resistance up to -20°C.

- In addition to hardness at Rockwell, Brinell and Vickers, the UCI durometer can test tensile strength of steel up to 1740 MPa. The UCI durometer comes standard with a manual probe with a test force of 50N, with which this probe can be measured direction-independently from any direction with no correction factor.

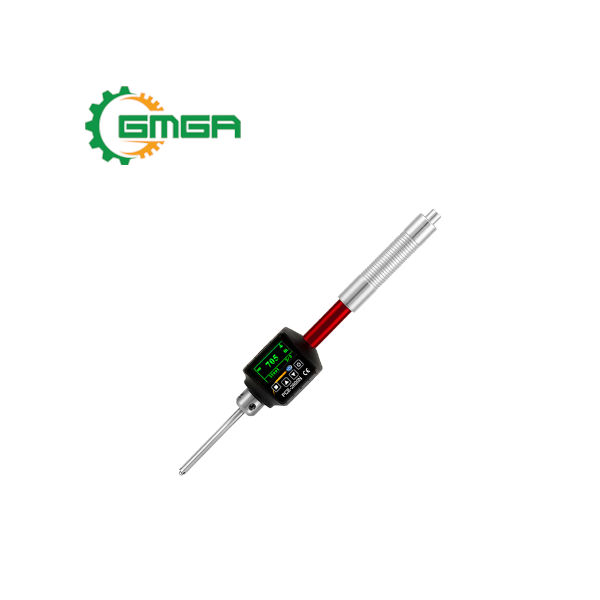

- Another advantage of the PCE-3000UL hardness tester is its NDT property. There is a Vickers diamond, excited in the ultrasonic frequency range at the transducer. Touching the diamond to the specimen surface reduces vibrations. The resulting frequency change is directly related to the surface hardness of the test piece. Due to the low test load, the diamond's penetration depth is very low, which is why only an almost invisible impression remains.

- The UCI durometer is therefore used for the control of small thin-walled components, for surface hardening specimens or for nitriding components. Hardness testers are also effective in measuring welds and controlling components with complex geometries.

- In addition to the UCI method, the PCE-3000 hardness tester can be equipped with a rebound probe. This allows the UCI hardness tester to be upgraded to the Rebound hardness tester. So, hardness tester users are two models to choose from the PCE-3000U with UCI Hardness Tester and the PCE-3000UL, complemented by a rebound hardness probe.

II. Advantages

- Non-destructive hardness testing

- Various hardness scales

- 5 materials can be tested

- Battery operated

- USB interface

- Can connect different probes.

III. Standard package

- 1 x UCI PCE-3000UL ultrasonic hardness tester

- 1 x UCI 50 measurement probe N N

- 1 x D type impact probe

- 2 x 1.5V NiMh Batteries

- 1x charger

- 1x USB Cable

- 1 x Instructions for use

IV. Specifications of Universal hardness tester PCE-3000UL

|

Technical specification for UCI hardness tester PCE-3000 |

|

|

Measuring Range |

Rockwell 20 ... 70 HRC |

|

Brinell 90 ... 450 HB |

|

|

Vickers 230 ... 940 HV |

|

|

tensile strength 370 ... 1740 MPa |

|

|

Measurement Accuracy |

± 1.5% HRC |

|

± 3% HB |

|

|

± 3% HV |

|

| Maximum Materialrauhigkeit |

10 N probe: 1.5 Ra |

|

50 N probe: 2.5 Ra |

|

|

rebound probe: 3,2 Ra |

|

|

Maximum Curvature Radius of the Surface |

UCI probes: 5.0mm / 0.19 in |

|

rebound probe: 10 mm / 0.39 in |

|

|

Minimum Weight of the Specimen |

UCI probes: 0.1 Kg / 0.2 lbs |

|

rebound probe: 5 kg / 11 lbs |

|

|

Minimum thickness of the test specimen |

UCI probes: 1 mm / 0.03 in |

|

rebound probe: 10 mm / 0.3 in |

|

|

Working Conditions |

- 20 ... 40 ° C / -4 ... 104 ° F |

| Dimensions |

Unit: 122 x 65 x 33 mm / 4.8 x 2.5 x 1.2 in |

|

UCI probe: Ø25 x 140 mm / 0.9 x 5.5 in |

|

|

rebound probe: Ø20 x 150 mm / 0.7 x 5.9 in |

|

|

Weight |

Device: 200g / 7.05 oz |

|

UCI probe: 250 g / 8.8 oz |

|

|

rebound probe: 100 g / 3.5 oz |

|

|

Power Supply |

2 x 1.5 V battery |

| Battery Life |

20 h |

No comments yet

SIGN UP FOR A CONSULTATION

Please fill in the form below and send your comments and questions to GMGA, we will respond to your email as soon as possible.

COMMIT

100% new product

COMMIT

100% refund if the product is of bad quality and not as promised

DELIVERY

Nationwide

Review Universal hardness tester PCE-3000UL

There are no reviews yet.