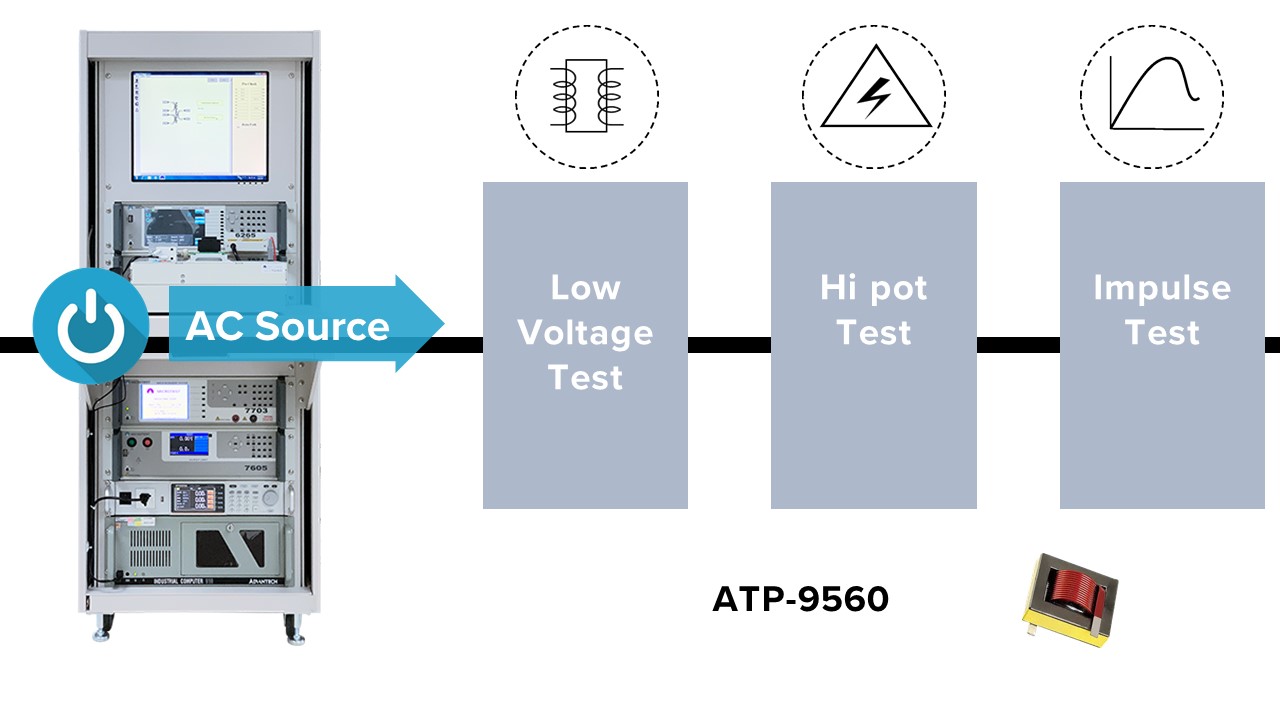

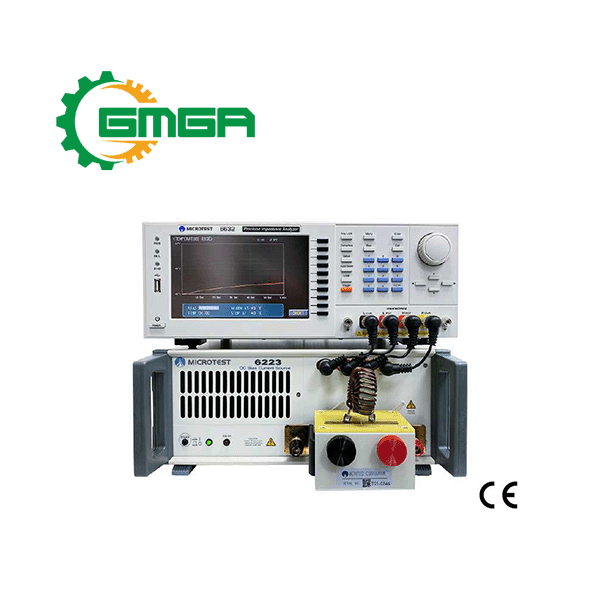

Automatic transformer test system MICROTEST ATP-9560 (3-in1+AC Source)

Price: Contact

| Model | ATP-9560 |

| Manufacturer | MICROTEST |

| Power supply | 90Vac-125Vac or 190Vac-250Vac |

| Weight | 190 Kg |

| Size | 600 x 1020 x 1555 mm |

| Condition | Stocking |

| Warranty | 12 months |

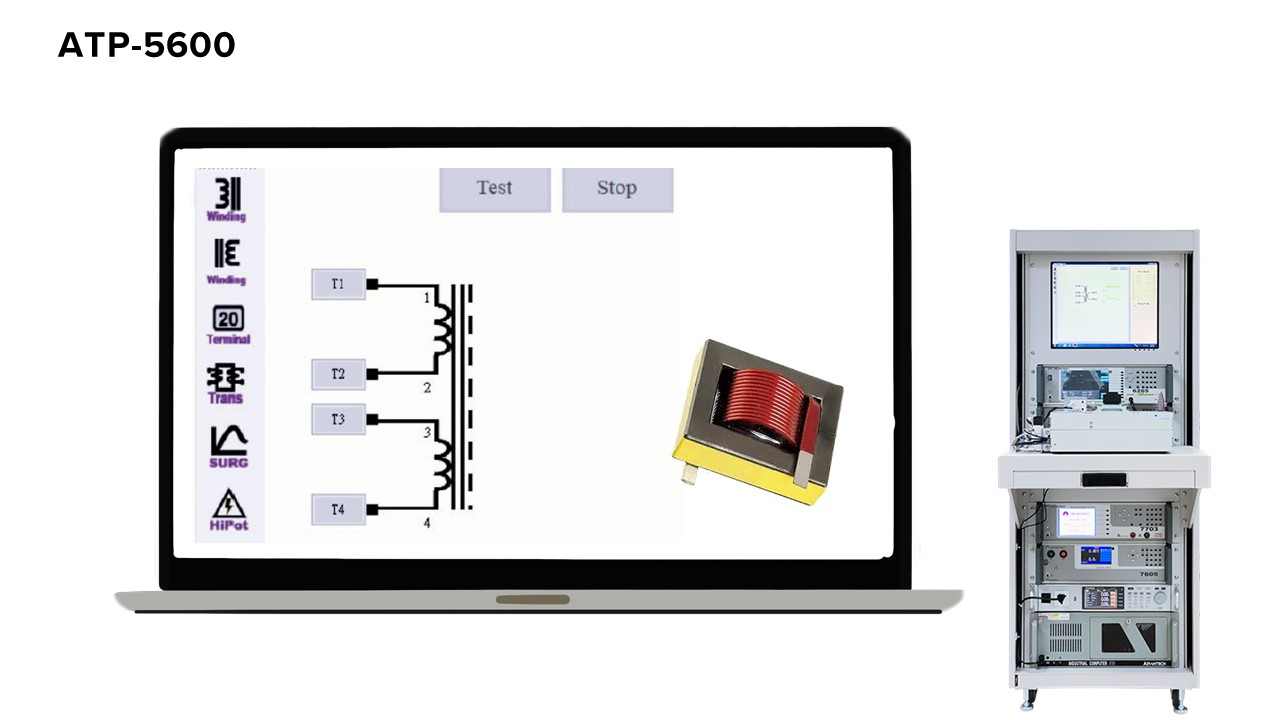

Automatic transformer test system MICROTEST ATP-9560 (3-in1+AC Source) controlled by a PC, it provides 20 test channels.

MICROTEST 9560 an AC source for dynamic testing of transformers (open-circuit voltage, excitation current, no-load power) and measures the inductance value of transformers. The optional LCR Meter offers test frequencies of 200kHz, 500kHz, and 1MHz.

I. Specification of Automatic transformer testing system MICROTEST ATP-9560

- Automatic transformer test system MICROTEST ATP-9560 (3-in1+AC Source) is a comprehensive measurement system that integrates low-voltage electrical characteristics and safety compliance testing into a single platform.

- The 9560 transformer test system combines low-voltage testing for transformers with AC/DC withstand insulation testing and interlayer short-circuit testing. The low-voltage testing includes parameters such as inductance value, leakage inductance, DC resistance, AC resistance, quality factor, capacitance value, turns ratio, and checks for shorted terminals. The safety compliance testing offers AC withstand voltage up to 5000V, DC withstand voltage up to 6000V, and maximum insulation impedance of 12000MΩ.

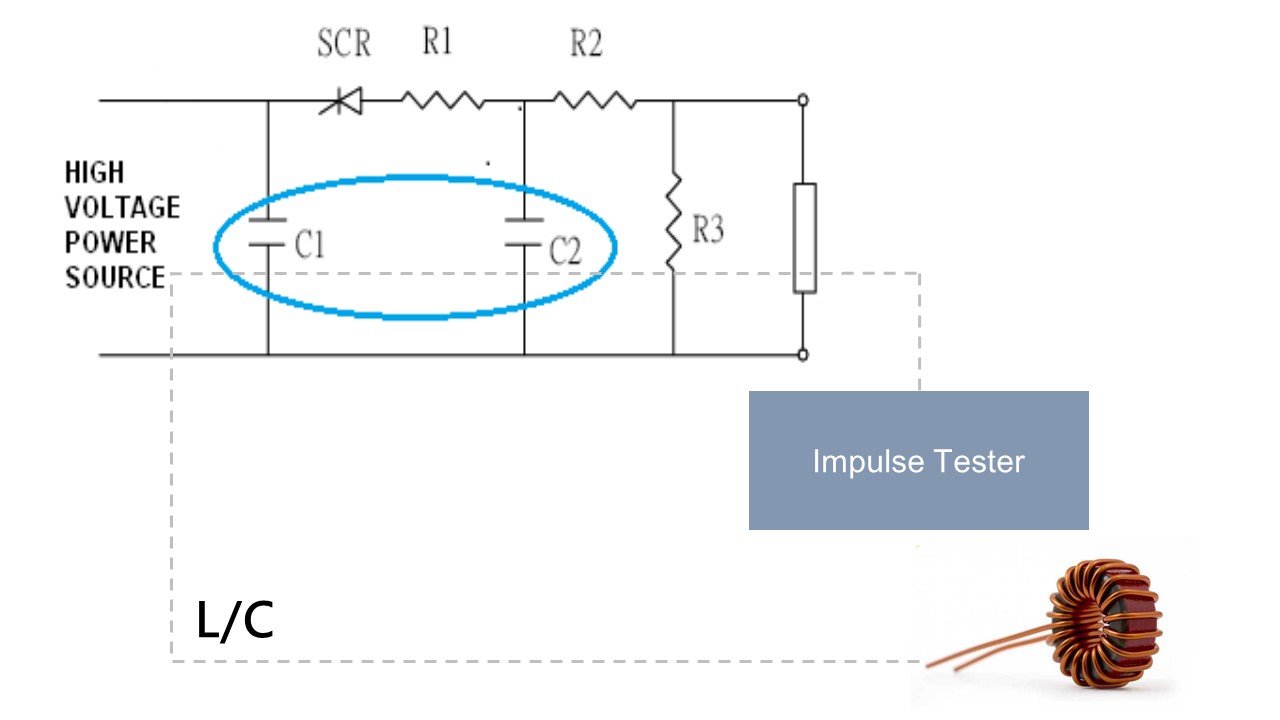

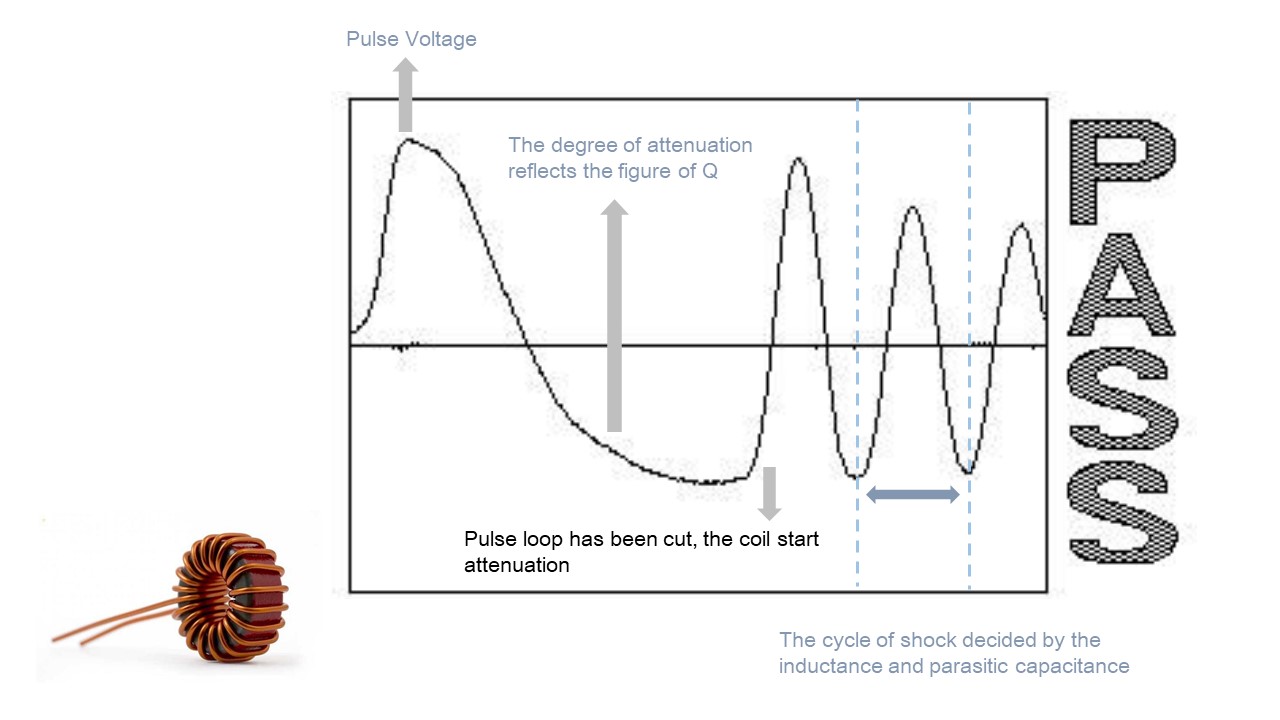

- The interlayer short-circuit test utilizes non-destructive high-voltage pulse testing technology. It analyzes the damping attenuation waveform generated by L/C resonance to detect short-circuit defects between transformer coils or insulation layers.

Features of MICROTEST ATP-9560:

- One-step integration for transformers HV and LV electrical tests

- 20 test channels

- AC Source 4 channels input

- Using 4-wire measuring method (up to 10 different windings)

- Electrical safety - AC Voltage Output 5000V

- Electrical safety - DC Voltage Output 6000V

- Electrical safety - Insulation Resistance 12000MΩ

- Test Frequency (200k/500k/1MHz)

- Low Voltage Electrical Test

- Hi pot/ Insulation Test

- Integrating impulse winding test function (Layer Short Circuit)

- Magnetizing current (2mA - 4.2A)

- Open circuit voltage (10mV -500V)

- No-load power consumption (0.2-500VA)

- Support 100mA DC bias (F7721).

Applications:

- SMPS transformers, Power transformers, Communication transformers, EMC filters, Magnetic components such as toroidal coils.

II. Main features of Automatic transformer test system MICROTEST ATP-9560 (3-in1+AC Source)

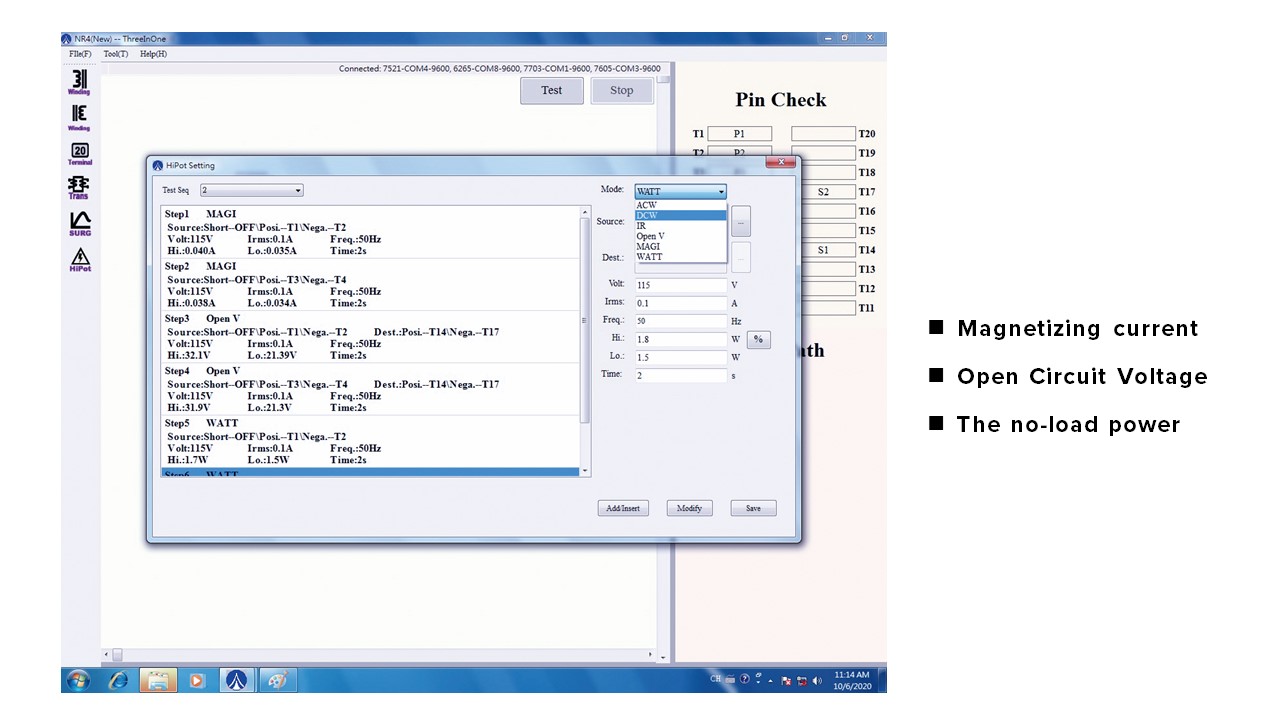

MICROTEST ATP-9560 support the AC Source test:

Excitation current:

- The huge excitation current could happen when the voltage restores after no-load or the removal of external defect. The reason is because of the saturation of core and the residual magnetism. The huge inrush current appears during the operation of the transformer due to the overload magnetic flux. The maximum current could be 6 to 8 times than rated current.

- Detecting excitation current must be measured under certain voltage condition to ensure that the excessive excitation current produces a large number of harmonics, which affect the quality of power supply or causes the voltage well or drop.

Open- circuit voltage:

- Open-circuit voltage is means input a voltage from primary coil and measure the no-load voltage from the secondary coil. The purpose is to make sure the loss that influence by the turn ratio and the excitation current from the primary coil.

The no-load power:

- Whether you’re a transformer or inductor manufacturer, the 3-in-1 Automatic Transformer Test System allows you to cost-effectively deliver the quality and reliability that your customers demand.

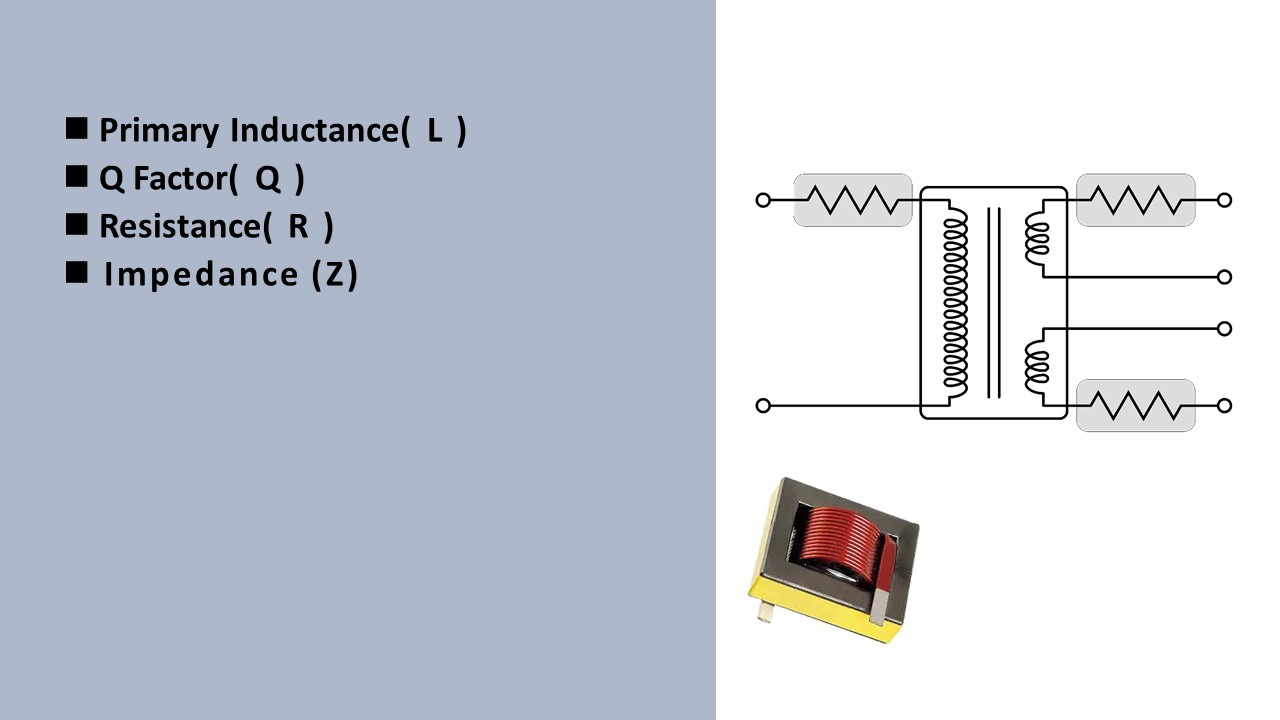

All-In-One Low voltage electrical test:

- Inductance (L)/Leakage Inductance/Turn Ratio/Resistance (DCR)/Resistance (R)/Balance/Capacitance (C)/Short Circuit.

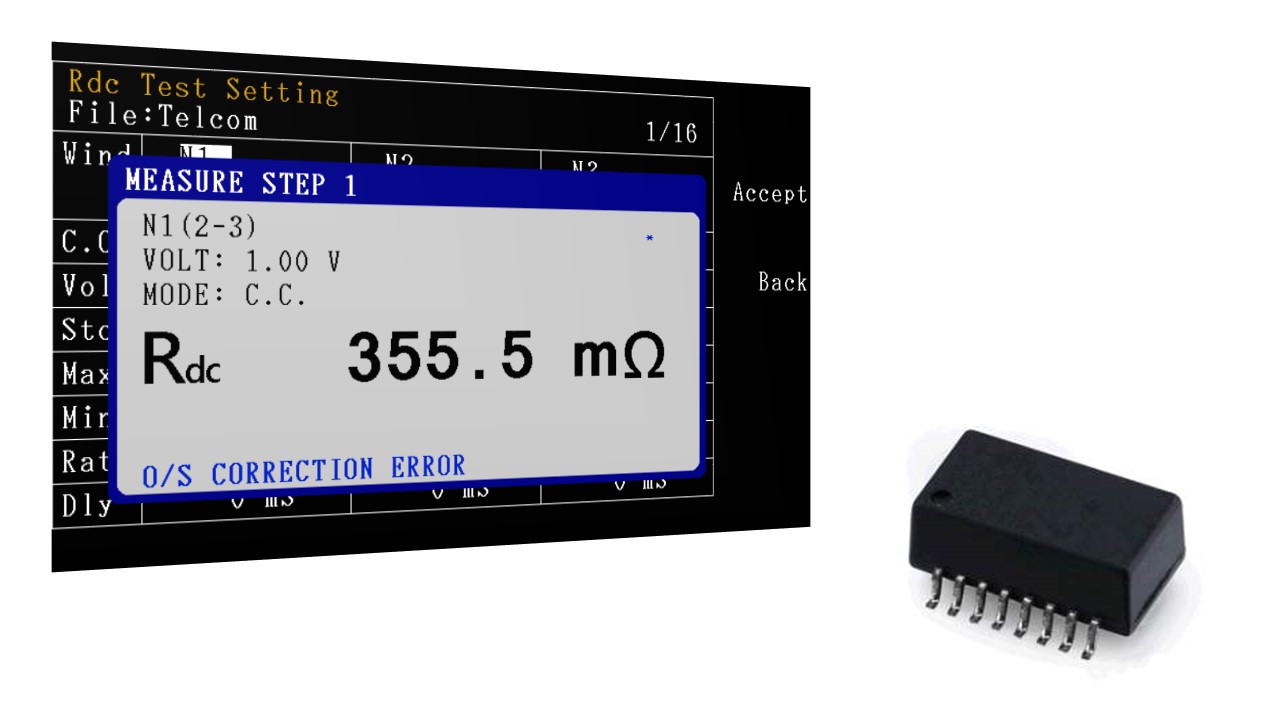

Automatic Balancing Bridge & 4-Wire DCR Test (DC Resistance):

- Check if the winding tension is improper for Transformer.

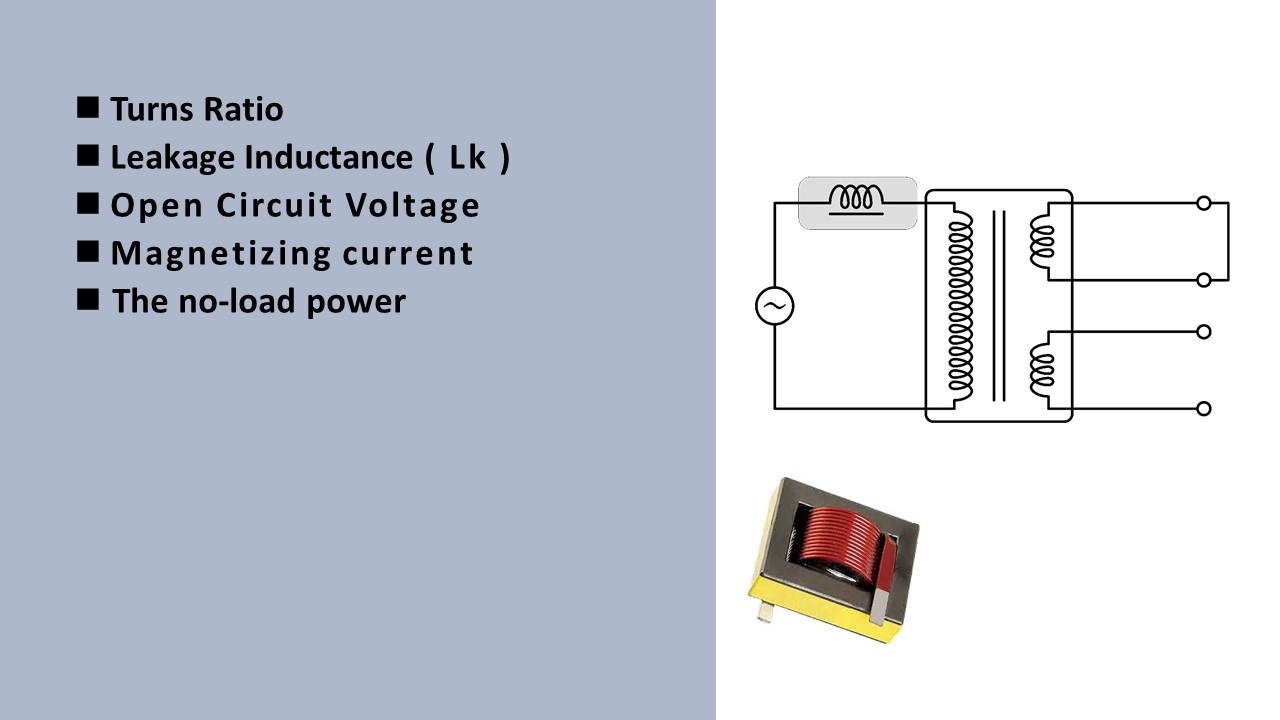

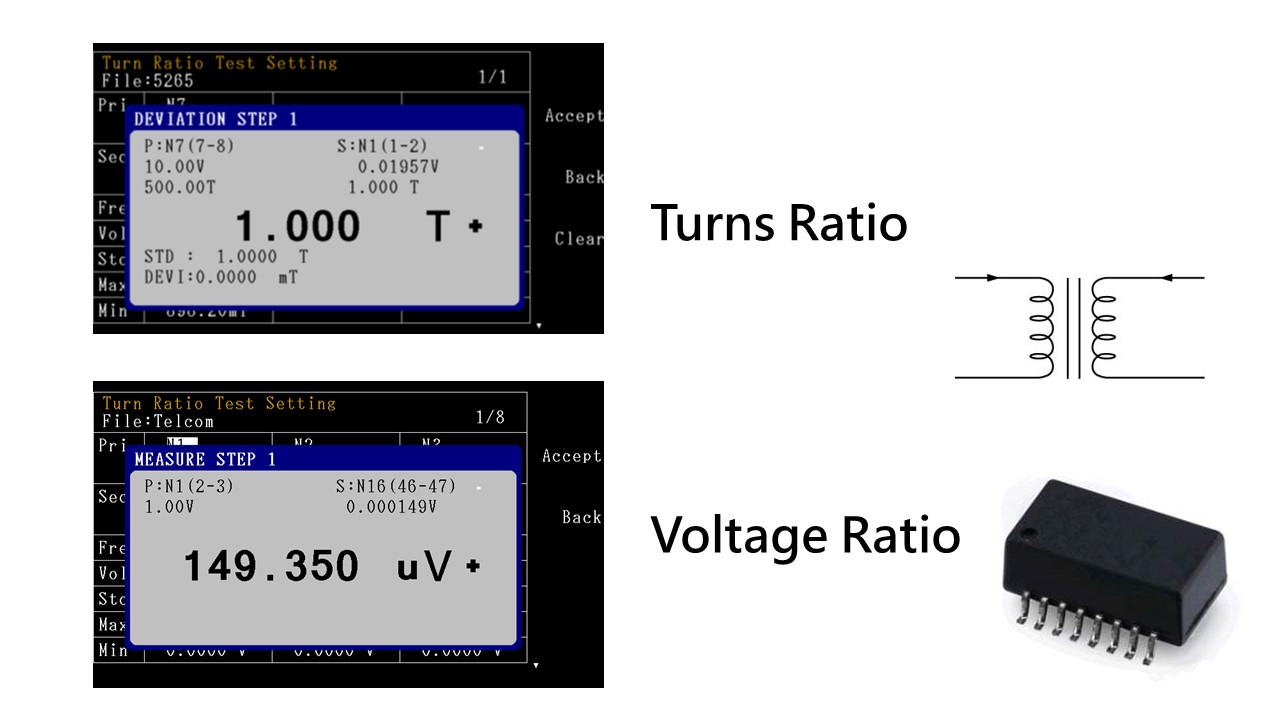

Turns ratio is an important parameter in transformer:

- Ideally, we can get the turns ratio by compare the input and output voltage. However, there are many parameters that might affect. So, there are some different ways to detect turns ratio.

|

TR Voltage |

Put a AC voltage on primary coil, and detect the voltage on secondary coil. Compare the turns ratio and phase. |

|

TRL Inductance |

Detect the inductance on each coil, and calculate the turns ratio. The turns ratio is more accurate on transformer with bigger leakage inductance. |

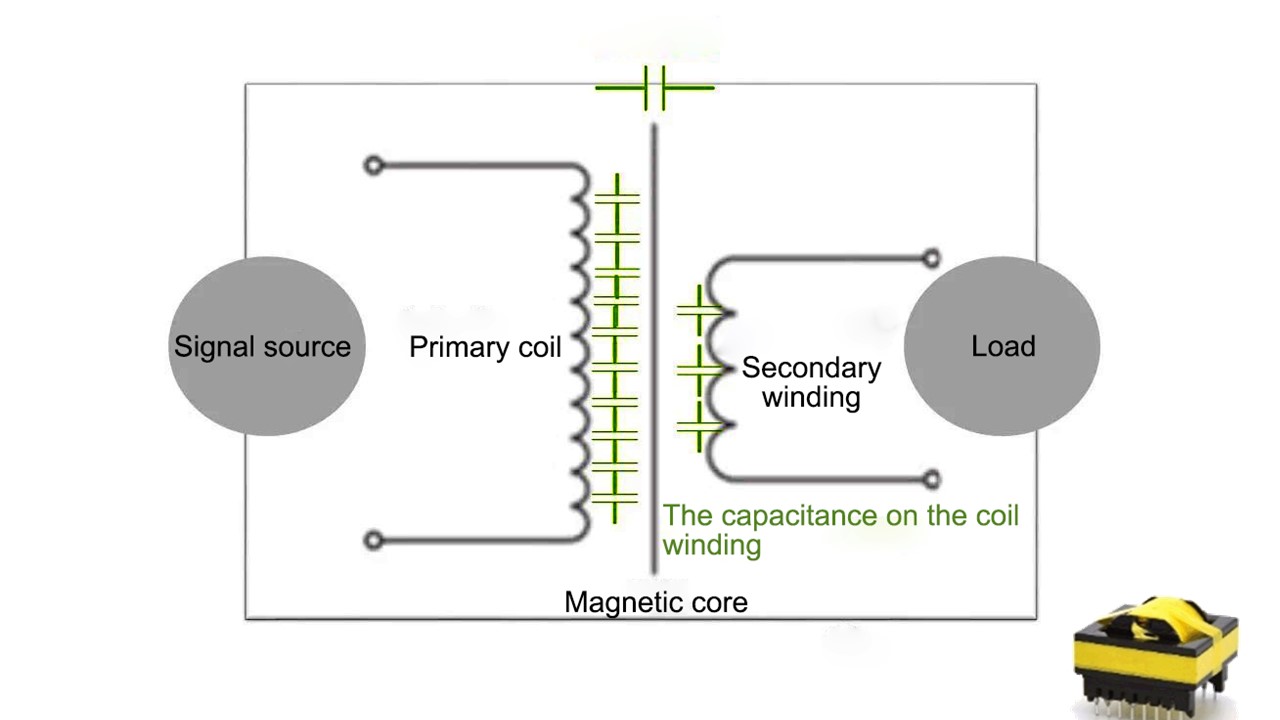

Detect capacitance to make sure the insulation between winding position and winding coil is enough:

- The winding coil on the transformer include distributed capacitance, it usually distribute between winding coil.

- Capacitance is usually represented by the capacitance by one winding to another winding in an equivalent circuit.

- Cs and Cp is an equivalent capacitance in series or parallel in equivalent circuit.

- D value is the ratio with AC resistance and capacitance, The lower the D value, is better.

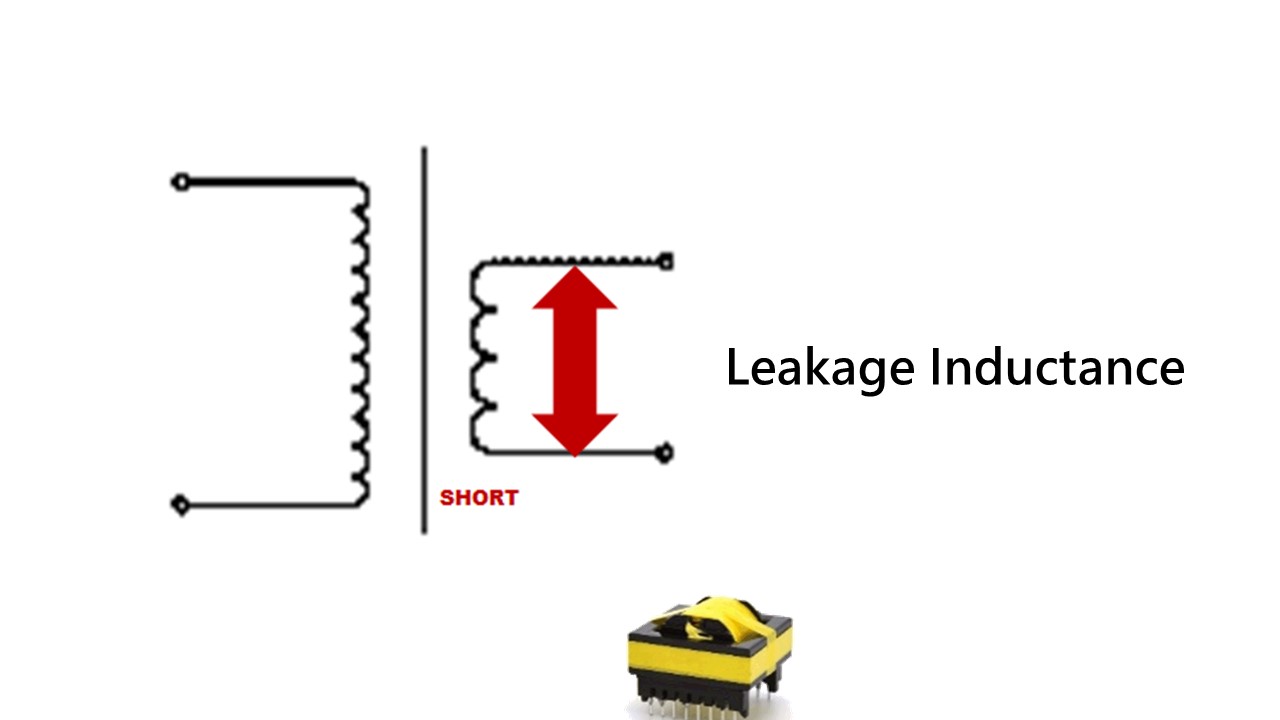

Test leakage by LCR balance bridge:

- When the instrument connect a primary coil with the transformer and the secondary coil is under open status, the test result L= Lp on primary coil + Leakage Current.

→ The leakage inside the instrument must short the secondary coil in the transformer.

A ideal secondary coil’s voltage will be 0V in short status. The voltage on both side of primary coil will be 0V. The inductance from primary coil will be the real leakage current.

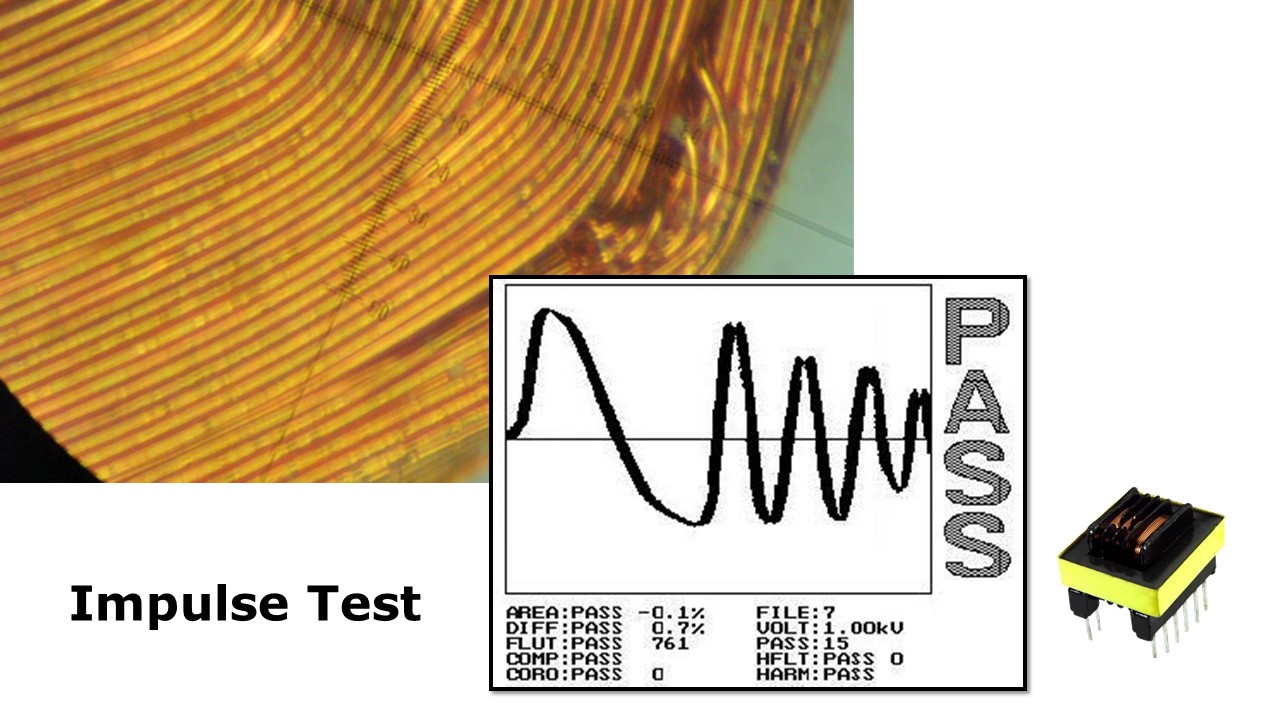

Impulse test:

- The transformer may have partial discharge under high voltage/current that could penetrate the insulation cover:

- Short time hipot testing is not able to detect the real life time of transformer, so, the impulse test is necessary.

Why do we need to do the impulse test?

- Recently, the voltage on the electronic product is increasing. The partial discharge may happen under instant high voltage/current leaking. This may cause the penetration on the wire.

- Short time withstanding test is not able to detect the product life of transformer. So, the inspection of impulse test is necessary.

HAutomatic transformer test system MICROTEST ATP-9560 use the non-destructive testing technology:

- Charge the inner capacitor until the setting voltage level, and discharge on the coil of the transformer. During this process, capacitor and inductor will create a set of amplitude-decreasing waveforms, and the instrument will analyze the pulse.

Safety certification testing items:

- AC Hipot

- DC Hipot

- Insulation Resistance

- Current Leakage.

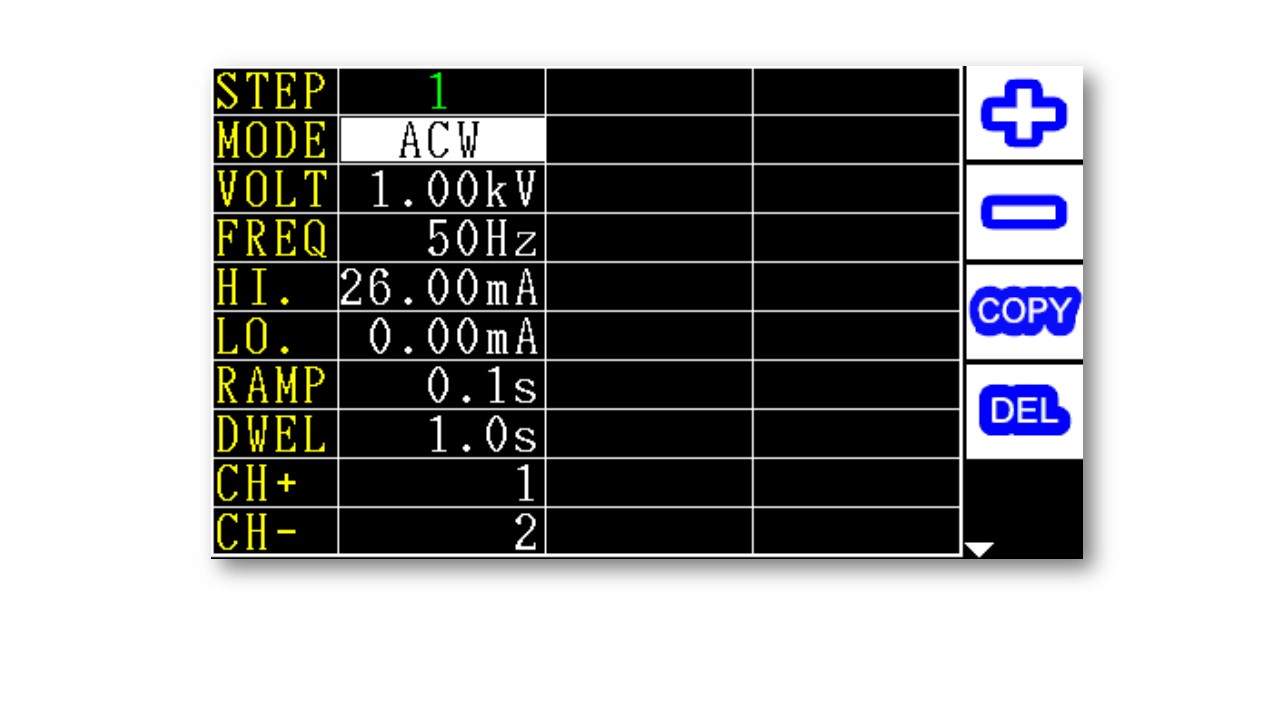

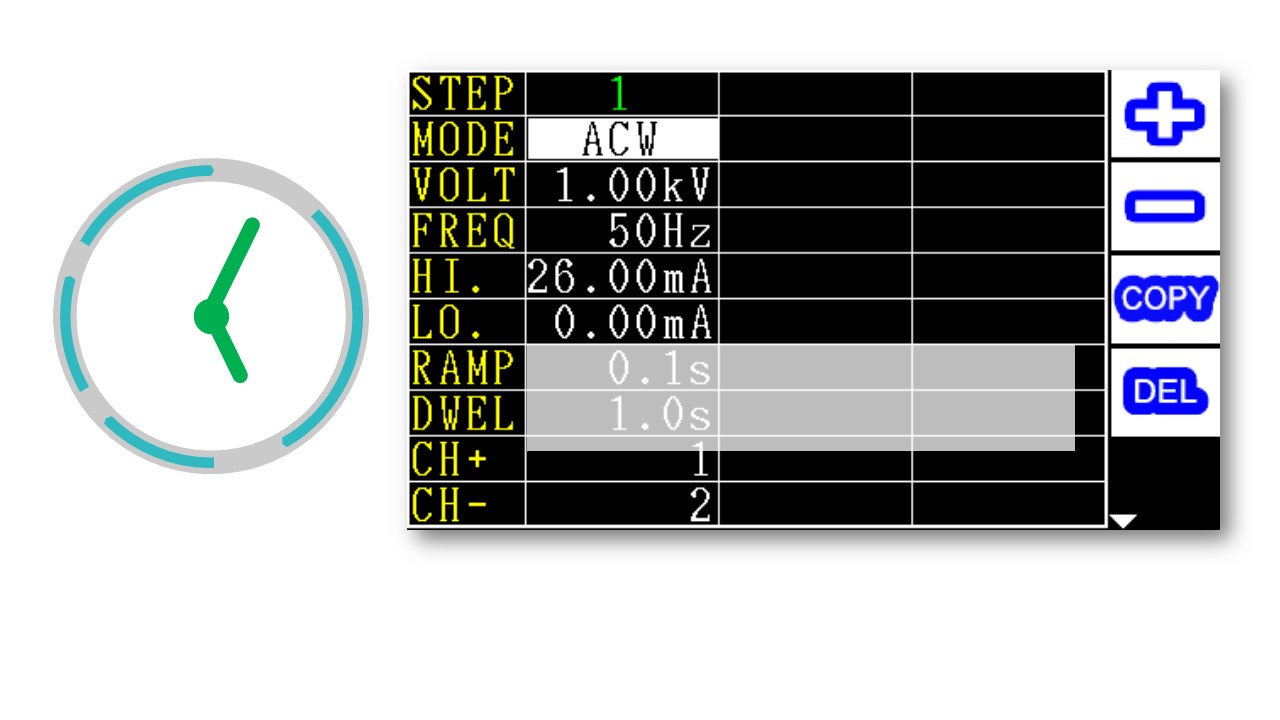

AC/DC withstanding voltage test:

- Difference between AC and DC.

|

AC Hi pot Test |

Most DUT have parasitic capacitance. With AC test, might not able to charge the parasitic capacitance. Therefore, this will create constantly current go through. |

|

DC Hi pot Test |

The parasitic capacitance will be charged under DC hi-pot test. Therefore, the current will reduce to almost 0. |

- Advantages for AC Test.

|

AC Hi pot Test |

AC test is same as our normal usage electricity. Also, AC is able to do positive and negative polarity test. |

|

DC Hi pot Test |

The parasitic capacitance on DUT has been charged under DC test, so the rest leakage current is the real current from DUT. |

- Disadvantage of AC/DC Hi-pot Test.

|

AC Hi pot Test |

If the DUT has huge parasitic capacitance, the current we detect will bigger then the actual current. To fulfill the necessary current for the capacitance of the DUT, the output current is much more than DC test. This is danger for the operator. |

|

DC Hi pot Test |

Testing Voltage has to increase from 0. To fulfill the necessary current for the capacitance of the DUT, the output current is much more than DC test. This is danger for the operator. The discharge process is necessary after DC hi-pot test. DC test can only do the single polarity test. |

Hi-pot test time:

The testing voltage is refer to the condition of DUT while doing Hi-pot test. If the voltage setting is too low, the insulation material defect might not be detected. If the voltage setting is too high and the testing time is too long, it may cause the permanent damage for the material.

TNormally setting for the safety standard.

- Formula →Testing Voltage= DUT recommend voltage × 2+1000V

- EX : DUT standard :240V →Setting test voltage:1480V.

Common way to safe time for testing.

- Testing time for most products is 60s. If there are more than one test on one item, it will cost a lot of time. This will lower the efficiency og the product line.

- Therefore, the product line usually shorter the testing time to 1~2 sec. and higher 10%~20% testing voltage.

What is insulation resistance test:

- VDE and TUV safety standard request insulation resistance test for some specific product before hi-pot test. The reason is to make sure the insulation will not be damaged while doing hi-pot testing. Insulation resistance test is the key item to evaluate the material.

- Hi-pot test is judge by leakage current, but IR test is judge by resistance, and usually it’s higher than 1 MΩ. It tests the DUT’s resistance between both terminal.

Why do we need to do IR test:

Confirm the performance of the structure of the insulation.

- The insulation structure should have higher insulation resistance rate by using better material.

- For the insulation material, the protection against electric shock of the switch must be guaranteed. Confirm the insulation structure can pass the reliability test(heat durability, insulation)

- The importance of insulation resistance. Before assemble the product, IQC has to do the IR test for every components, such as switches, transformers, resistors, capacitors, inductors, PCB, wire or cable to make sure the quality.

Leakage current test:

→Measuring Tiny AC Leakage Current

- DUT has tiny parasitic capacitance. This characteristic will create leakage current by resistance. Capacitor is a resistance component under AC voltage. This may cause the test result include the leakage current inside the instrument. If the DUT has low leakage current, we must consider capacitance , frequency, and the voltage we put.

Arc detection:

- The surface or interior of the insulation material might discharge under high voltage test. Because of the lost of insulation performance, DUT may have temporary of discontinuity discharge.

- Because that temporary discharge can’t be judge by leakage current, so Hi-pot tester will judge the defect product by the changing rate of testing voltage or leakage current.

- Arc test is a geometric not a constant test. Also, the detection will be affect by the wire’s impedance or capacitance between the detectors. The rate of change of the current will be affect in the Arc detection.

Technical specifications of Automatic transformer test system MICROTEST ATP-9560 (3-in1+AC Source)

|

Model |

ATP-9560 |

||

|

Test Channel |

21 |

||

|

Dynamic Testing For Transformer |

|||

|

Excitation Current |

2mA-4.2A |

Measurement Signal |

|

|

Open- circuit voltage |

10V-5000V |

||

|

The no-load power |

0.2-500VA (External AC Source) |

||

|

Low Voltage Electrical Test |

|||

|

Model |

6265 |

6266 |

6267 |

|

Frequency |

10Hz-200kHz |

10Hz-500kHz |

10Hz-1MHz |

|

Frequency Resolution |

5 digits |

||

|

Basic Accuracy |

±0.1% |

||

|

AC Drive Level |

10mV-2Vrms |

||

|

DC Drive Level |

10mV-2V |

||

|

Output Impedance |

100Ω |

||

|

Turn |

Inductance or Voltage |

||

|

Test Mode |

Meter Mode / List Mode |

||

|

Parameters Measurement |

Inductance (L)、Impedance (Z)、Capacitance (C)、Resistance (R)、Conductance (G)、Susceptance (B)、Admittance (Y)、Alternating Current Resistance (ACR)、Quality Factor (Q)、θ、Direct Current Resistance (DCR)、Leakage Inductance、Turn Ratio、Balance、Short Circuit |

||

|

L, LK |

0.1nH ~ 9999.99H |

||

|

C |

0.00001pF ~ 999.99mF |

||

|

Q,D |

0.00001 ~ 99999 |

||

|

Z,X,R |

0.00001Ω ~ 99.9999MΩ |

||

|

Y |

0.01nS ~ 99.9999S |

||

|

θ |

-180°~ +180° |

||

|

DCR |

0.1mΩ ~ 99.999 MΩ |

||

|

Turn |

0.1 ~ 99999.9 turns |

||

|

Pin-Short |

12 pairs, between pin to pin |

||

|

Hi pot/ Insulation Test |

|||

|

Items |

AC Hi pot |

DC Hi pot |

IR |

|

Output Voltage |

10V-5000V |

10V-6000V |

10V-1000V |

|

Voltage Resolution |

1V |

1V |

1V |

|

Voltage Accuracy |

±(3% of setting+5V) |

||

|

Test Range |

0.001-31mA |

0.001-11mA |

1-12000MΩ |

|

AC Arcing Detection |

0-20 |

0-10 |

– |

|

Measuring time |

0.1-999s |

||

|

Ramp Time |

0.1-10s |

||

|

Time Resolution |

0.1s |

||

|

Impulse Test |

|||

|

Impulse Voltage |

200V-5000V |

||

|

Area Differential |

Add up the difference between normal wave and DUT wave call “ Area differential”. By calculating and comparing the deference of area between golden sample and DUT. To determine the degree of waveform overlap. |

||

|

Waveform Comparison |

Set a acceptable wave range, if the DUT’s wave is in this range shows “pass” otherwise, “fail” |

||

|

Corona |

In pulse test, the insulation defect will cause discharge and create corona. This function is able to count the times that corona happened base on the degree of deviation. |

||

|

Flat |

If the layer short happened, the waveform will tremble. Therefore, the instrument will quantize and compared it. |

||

System:

|

Electronic Rack |

|

|

Stroage |

Unlimited storage (By The PC Link) |

|

Power Supply |

Voltage 90Vac-125Vac or 190Vac-250Vac |

|

Power consumption |

1000VA/set |

|

Dimension (W*H*D) |

600*1020*1555mm (W*H*D) |

|

Weight |

190kg |

|

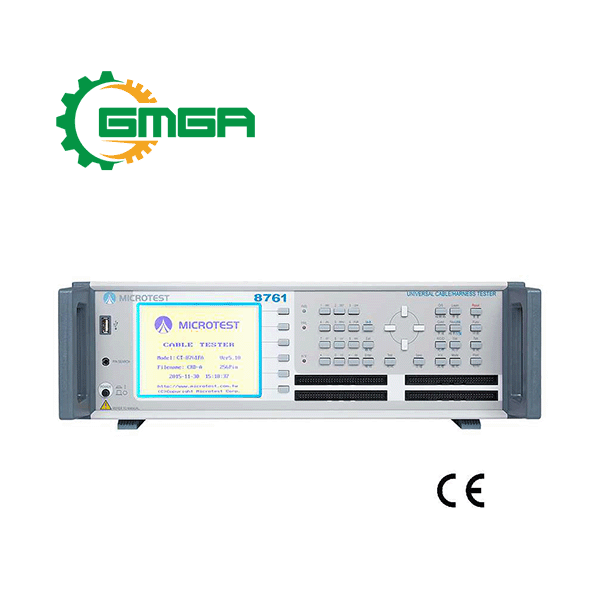

Benchtop Instrument |

|||

|

Model |

Transformer Tester |

Impulse Tester |

Hi pot Tester |

|

6265/6266/6267 |

7703 |

7605 |

|

|

Power Supply |

Voltage |

Voltage |

Voltage |

|

Frequency:47-63Hz |

Frequency:50/60Hz±5% |

Frequency:50/60Hz±5% |

|

|

Dimension (W*H*D) |

435x145x522 mm (W*H*D) |

435x190x522 mm |

365x145x430 mm (W*H*D) |

|

Weight |

9 Kg |

14kg |

15kg |

|

Interface |

RS-232、Handler、LAN、USB Host、EXT. I/O |

RS-232、Remote、Printer |

RS-232、Remote、USB Host、USB Device、EXT.I/O |

|

Displa |

Color Screen, 7″ TFT (800*480) |

5.7″ TFT (320*240) |

Color Screen, 4.3″ TFT (480*272) |

No comments yet

SIGN UP FOR A CONSULTATION

Please fill in the form below and send your comments and questions to GMGA, we will respond to your email as soon as possible.

COMMIT

100% new product

COMMIT

100% refund if the product is of bad quality and not as promised

DELIVERY

Nationwide

Review Automatic transformer test system MICROTEST ATP-9560 (3-in1+AC Source)

There are no reviews yet.