Bioreactor tank small scale Esco BioXcell ® with stirrer

Price:

| Model | |

| Manufacturer | |

| Power supply | |

| Weight | |

| Size | |

| Condition | |

| Warranty |

I. Specifications of Esco BioXcell ® paddle cell culture machine

- This compact Esco BioXcell ® stirred tank bioreactor features a small footprint to save space in your laboratory.

- BioXcell ® control towers are combined with 2 L or 10 L flasks for microbial, fermentation and cell culture applications. Whether you are in the early stages of research and development, this bioreactor is available in flexible configurations to fit your needs.

Principle of stirring in Esco BioXcell ®:

- The impellers are interchangeable in this Esco BioXcell ® stirred tank bioreactor; provides sufficient rapid stirring for efficient distribution and homogenization within the bioreactor.

- Different impeller designs provide different fluid dynamics to utilize suitable mass transfer proteins for higher product yield.

Advantages of agitated bioreactor Esco BioXcell ®:

- Perfect fit for research and development

- Combination technology: multiple glass jars or single-use jars

- 1:2 for mammalian cells

- 1:3 for microorganisms/fermentation

- Expandable from bench to research

- Siemens PLC HMI software with user-friendly touch screen interface; Intuitive for real-time monitoring

- Compact design to save critical lab space

- Configurable peristaltic pumps. Easily assemble tubes for fluid addition or removal

- Rotameters - Air Flow Control

- Interchangeable impeller/cutter to solve user's requirement

- Processing Modes: Batch, Fed-Batch, and Perfusion.

Applications of Esco BioXcell ®:

- Microbial Cells

- Insect cells

- Mushroom

- Mammalian cells in suspension.

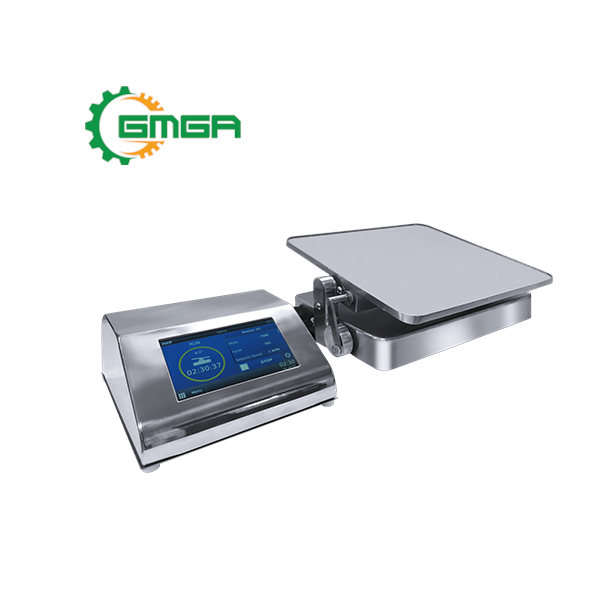

BioXcell ® control tower:

II. Highlights of the Esco BioXcell ® bioreactor

Combined technology:

- Single-use components facilitate a more robust approach as it eliminates cleaning validation steps and more. The Esco BioXcell ® bioreactor is a hybrid technology that can choose to use a single-use or multiple-use flask. Sterilizers such as glass and stainless are mainly used in laboratories for ease of production scale-up. Reusable vessels have a long history in the manufacturing areas of the bioprocess industry. Not only is there a wealth of experience and established protocols in single use, but also the capacity it can provide as opposed to single use.

- This hybrid technology maintains production capacity while building confidence in user requirements. Deployment of single-use systems is more efficient and cost-effective while hybrid technology, even with established methods and protocols, provides a practical way to culture microorganisms at production scale.

FAVORABLE |

|

|

Single use |

Use a lot of times |

| Increased flexibility of product base |

Well established; conventional method |

|

Pollution from low to zero |

Implementation of other technologies through fixed pipeline |

| Reduce capital costs such as testing equipment and facilities |

Available in large capacity |

|

No need to clean |

Advanced measurement and control parameters |

DEFECT |

|

|

Single use |

Use a lot of times |

| Limited scalability (not suitable for production scale) |

Infrastructure is not flexible |

|

Use a lot of times |

Clean and confirm the process |

| Learning curve (adapting to new technology) |

High utility costs |

|

Damaged main ship parts may cause leakage |

Piping problems |

| Extracts and detergents |

Contamination can occur if not cleaned and sterilized properly |

Propeller design:

- The impeller inside the Esco BioXcell ® stirred bioreactor is suitable for internal mixing of different ingredients; to achieve homogeneity. It is also responsible for breaking the bubble formation during aeration in culture. Propellers are usually mounted top-down or bottom-up or side-mounted. It is installed in a propeller shaft that is usually circular and oriented perpendicular to the bottom of the bioreactor.

- Based on the bioreactor's liquid viscosity, different impellers should be used to achieve higher tip speeds corresponding to the running culture conditions. There are propellers, turbines, paddles, and more that operate at faster speeds than standard speeds. As scale increases, proper mixing is important to reduce adverse effects during microbial culture.

Radial impeller:

- The Rushton turbine is the best example of a radial flow propeller commonly used in a standard stirrer bioreactor. This type of propeller offers good air dispersion and bubble breaking resulting in high mass transfer.

Axial line propeller:

- The propeller-type impeller allows the liquid flow directly inside the bioreactor to be stirred. The propeller styles commonly used for cultures have low viscosity due to their relatively higher tip speeds. Since they are generally operated faster, one must ensure that gas-liquid dispersion is achieved.

***You may be interested in GMGA's ART workstation - Esco Vietnam: https://gmga.vn/en/danh-muc/process-equipment/workstation-art/

***You may be interested in GMGA's ART workstation - Esco Vietnam: https://gmga.vn/en/danh-muc/process-equipment/workstation-art/

III. Thông số kỹ thuật bioreactor tank small scale Esco BioXcell ® with stirrer

|

UTILITY |

|||

| CONTROL TOWER | Electrical connection |

230 VAC Single Phase 30A |

|

|

Housing |

Stainless Steel | ||

| Water |

Quick connect Water supply pressure requirement: 1.5 M |

||

|

Gas Supply (air, O2, N2, CO2) |

Push-connect fittings accept ¼ in. tubing or hose barb fitting Requirement: 10psig (0.69 barg) | ||

| Overall Dimension (W x D x H) |

350 x 692 x 925 mm |

||

|

Vinterface |

Colored Touch Screen Siemens HMI TP700 Siemens PLC S7 1200 | ||

| Features |

Real-time dynamic display |

||

|

Record Output |

USB port to save data to an external flash drive | ||

| Vessel Feature | BioXcell® 2 L |

BioXcell® 10 L |

|

|

Nominal Volume |

2 L | 10 L | |

| Working Volume | 1-2 L |

3-10 L |

|

|

Tank Nominal Weight |

5 kg | 852 mm | |

| Maximum Height (with condenser) | 520 mm |

852 mm |

|

|

Maximum Outer Diameter |

220 mm | 220 mm | |

| Agitation | Drive |

Small AC servo motor with automatic feedback compensation capable of low speed, high torque |

|

|

Sensor |

Incremental encoder TTL 2500 ppr | ||

| Range |

1-1200 rpm |

||

|

Precision |

1 rpm | ||

| Impeller |

2x Rushton Turbine Impeller *Configurable designs based on user requirement |

||

|

Baffles |

Inclusive in Standard Vessel | ||

| Temperature | Operating Conditions |

Ambient Temperature |

|

|

Precision |

±0.01 | ||

| Sensor |

PT 100 |

||

|

Control |

Heating Pad | ||

| pH | Range |

2-12 |

|

|

Precision |

±0.01 | ||

| Probe |

Analog/Digital Mettler Toledo |

||

|

Probe Length |

BioXcell® 2 L: 225 mm BioXcell® 10 L: 325 mm | ||

| Control |

Fermentation: Acid/Alkali Addition Cell Culture: CO2 /Alkali Addition |

||

|

DO |

Range |

Display Range: 0-200% Setting Range: 0-100% | |

| Precision |

±0.01% |

||

|

Probe |

Analog/Digital Mettler Toledo | ||

| Probe Length |

BioXcell® 2 L: 225 mm BioXcell® 10 L: 325 mm |

||

|

Control |

Gas Injection through Sparger | ||

| Delivery |

Ring Sparger |

||

|

Options |

Mass flow controller Oxygen Enrichment Device Second Gas Port (O2, N2, CO2, or other gases) | ||

| Oxygen Transfer Rate | |||

|

Condenser |

Filter | 0. 2µm PTFE filter | |

| Condenser |

Stainless Steel Condenser |

||

|

Peristaltic Pumps |

Number | 4 built-in, configurable peristaltic pumps | |

| Configurations |

Alkali, Acid, Feed, Antifoam |

||

|

Pump head |

Watson Marlow or Equivalent | ||

| Tube Sizes |

Default: 3.2 mm *Configurable depending on user requiremnt |

||

|

Fixed Speed |

20-200rpm | ||

| Flowrate |

9.4 to 95mL/min |

||

No comments yet

SIGN UP FOR A CONSULTATION

Please fill in the form below and send your comments and questions to GMGA, we will respond to your email as soon as possible.

COMMIT

100% new product

COMMIT

100% refund if the product is of bad quality and not as promised

DELIVERY

Nationwide

Review Bioreactor tank small scale Esco BioXcell ® with stirrer

There are no reviews yet.