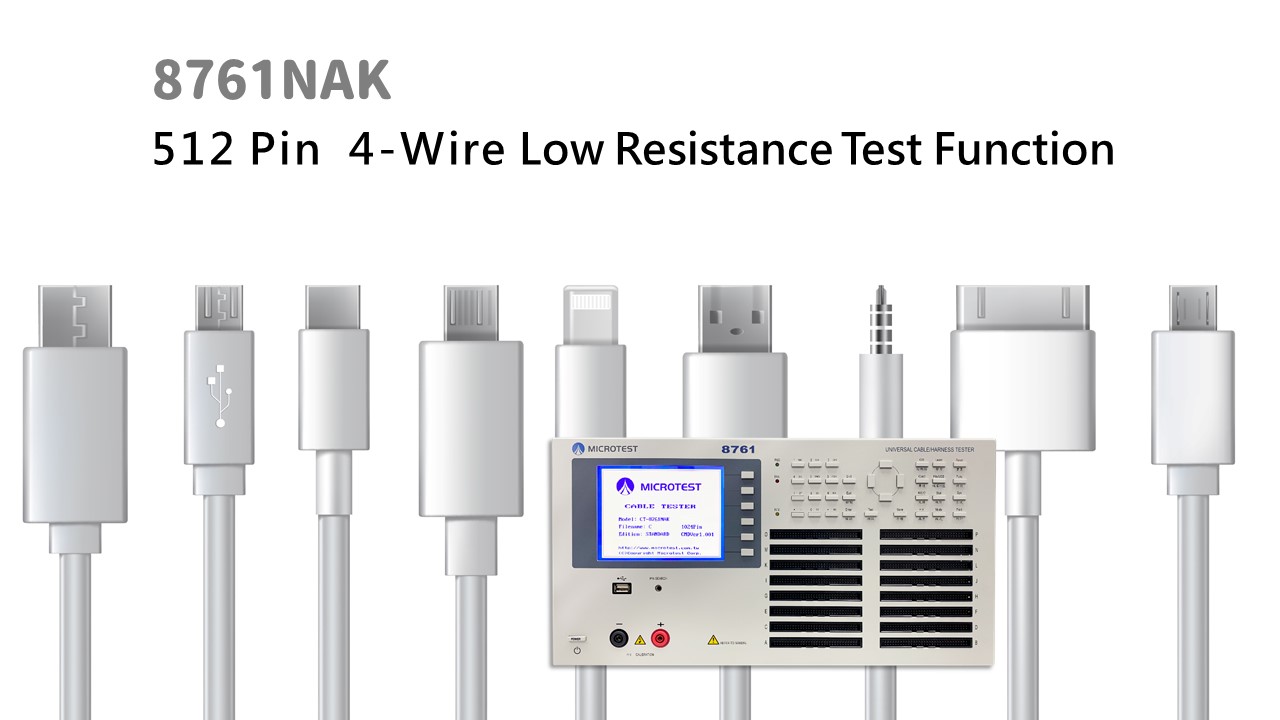

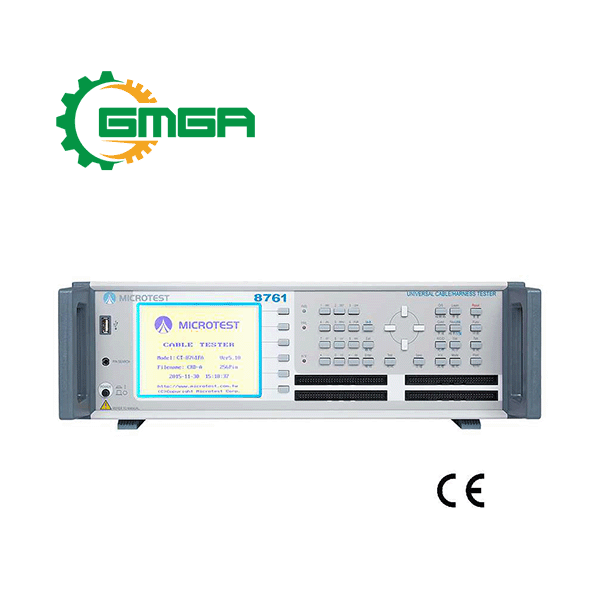

4-Wire cable harness tester MICROTEST 8761K series

Price: Contact

| Model | 8761NAK / 8761NK |

| Manufacturer | MICROTEST |

| Power supply | 115/230 Vac ±10% |

| Weight | 18 Kg |

| Size | 435 x 270 x 360 mm |

| Condition | Stocking |

| Warranty | 12 months |

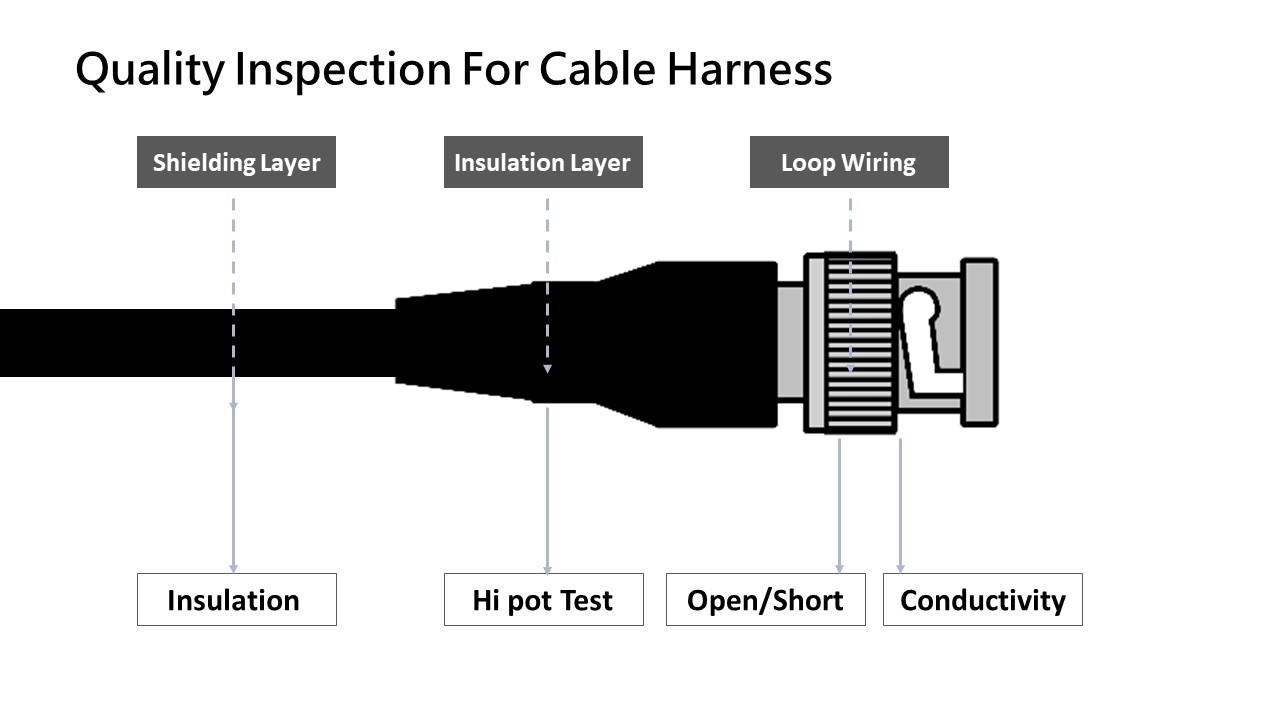

4-Wire cable harness tester MICROTEST 8761K series include testing capabilities: continuity impedance, open/short circuit, AC/DC safety withstand voltage, IR insulation, and component testing (resistor/capacitor/diode).

I. Specifications of 4-Wire cable tester equipment MICROTEST 8761K series

4-Wire cable harness tester MICROTEST 8761K series employs precise four-wire measurement technology to perform comprehensive electrical characteristic tests on wire harness products with low resistance levels of 1mΩ.

The testing points are selectable up to 512 points, with a maximum AC withstand voltage output of 700V and a maximum DC withstand voltage output of 1000V.

MICROTEST 8761K series supports PC connectivity software and BAR Code scanning, meeting the requirements for automated line testing in wire and connector production.

- 4-wire measurement, conductance resistance: 1mΩ-52Ω

- Low resistance scanning test 10mΩ-52Ω

- Test pin 512

- Number of test file up to 500 sets

- Open/Short

- Conductance resistance test

- AC/DC Hipot Test

- DC insulation

- Support bar code scan and print function.

Application of MICROTEST 8761K:

- All kinds of wires, connectors and combined products of connectors and wires.

II. Main features of 4-Wire cable harness tester MICROTEST 8761K series

4-Wire test:

- Connect to DUT directly to prevent any deviation.

- For measuring low resistance DUT, we recommend to choose 4-wire tester.

|

Conductance |

Detect the contact resistance in the cable connector. The conduction resistance is over the standard. |

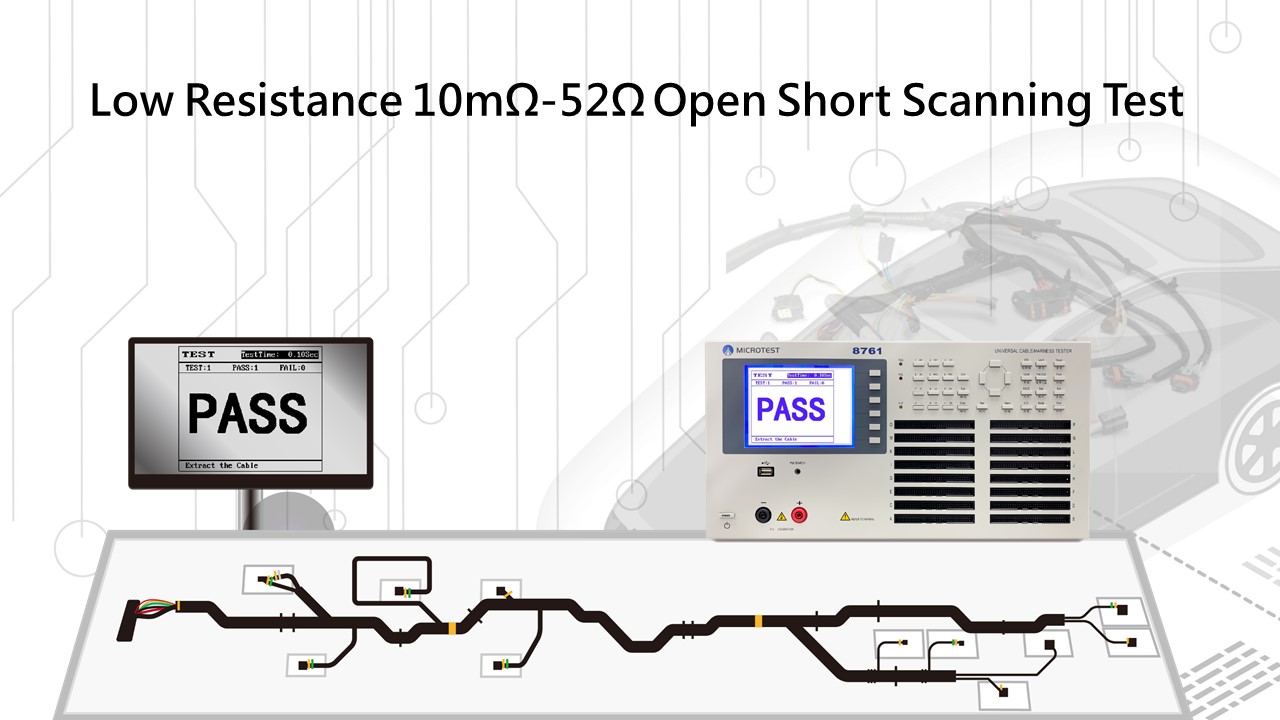

Low resistance scanning test 10mΩ-52Ω:

|

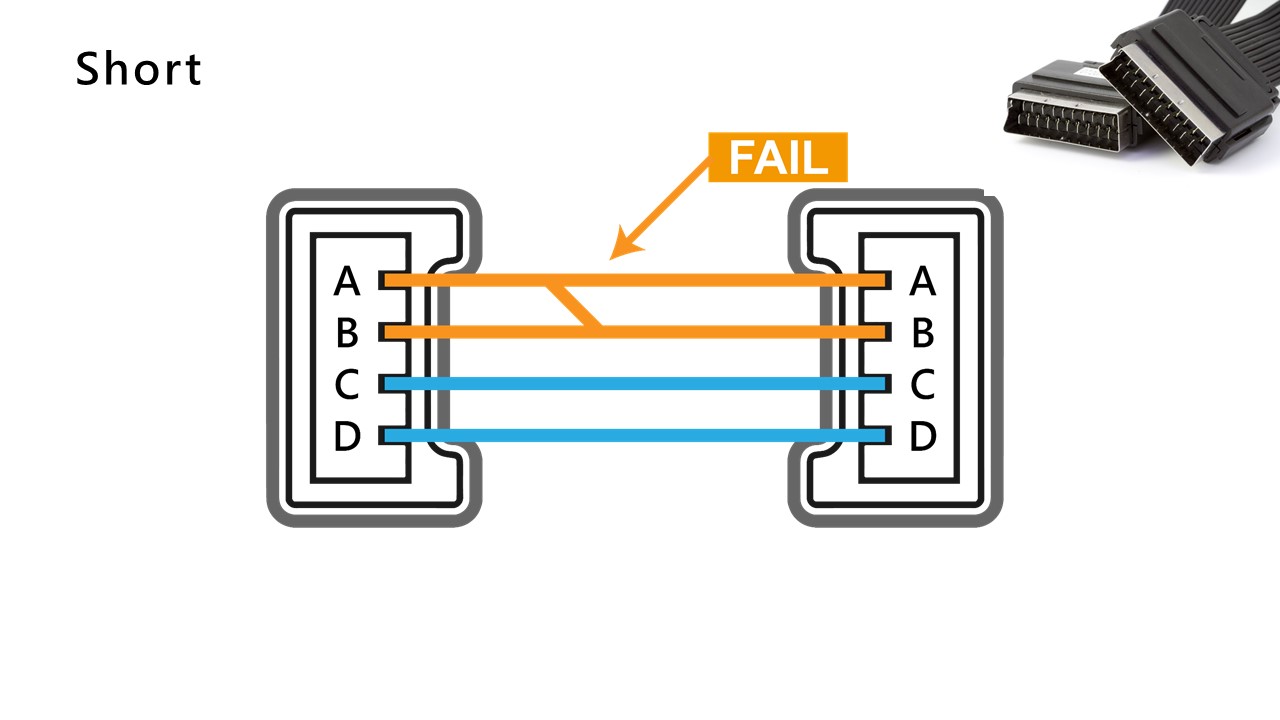

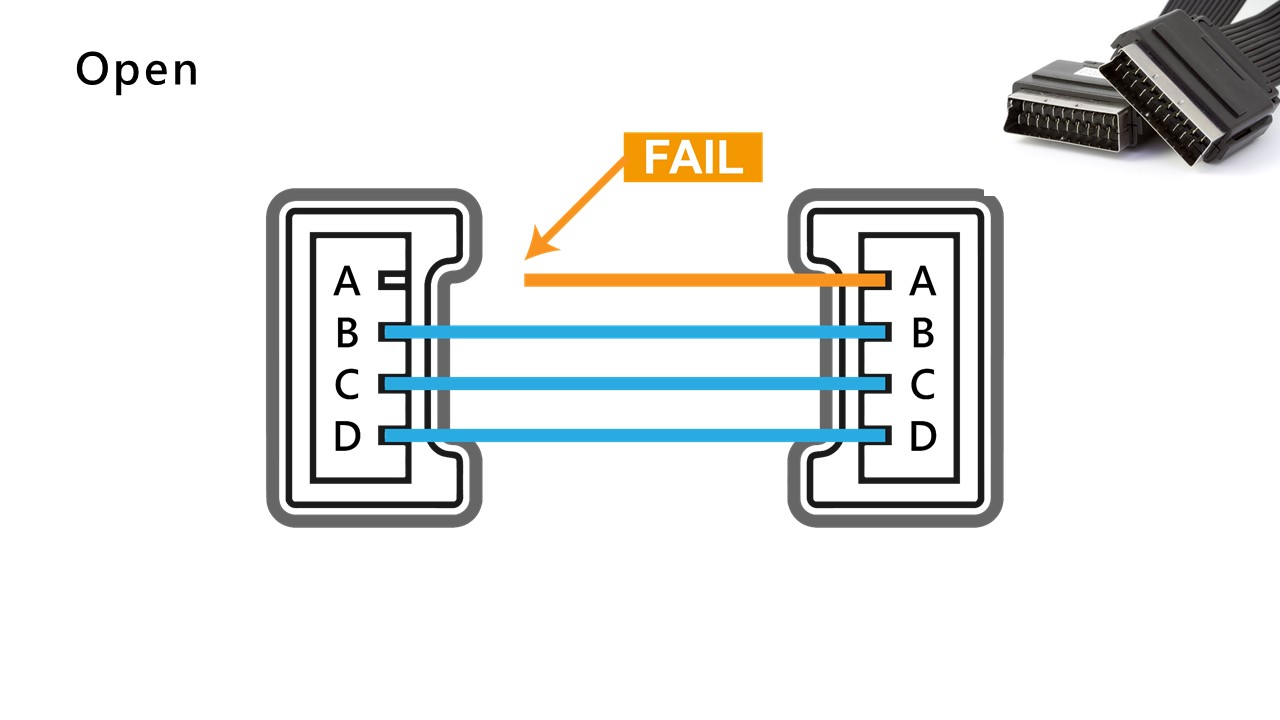

Open/Short test |

Make sure the contact of wire work properly. Open: The wire should be contact, but it doesn’t Short: The wire shouldn’t be contacted, but it does. |

|

|

Common production defect:

- Insulation layer or dislocation might happen during manufacturing process. That may cause poor connection or insulation.

Electrical Inspection:

- Conductivity test: Detect the contact resistance problem on the terminal

- Hipot Test: Detect the circuit contact fit the insulation value

- Resistance Test: Detect the O/S problem on the contact point of the terminal.

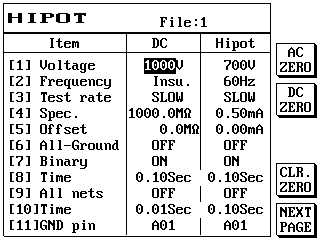

Safety test- HI POT test & insulation resistance test:

|

Hipot test |

Put a stabile high voltage on cable to make sure the quality of DUT · DC insulation The result will judge by the rate of insulation resistance. Insulation resistance defect may cause DUT be penetrated or leakage current under high voltage. · Arc test. Some high precision product for automobile and military can’t accept any arc under high voltage. Inspect the loop contact in the connector fit the request of insulation and voltage. Insulation resistance between loop is lower than the standard. The voltage resistance is lower than the standard that cause leakage current. |

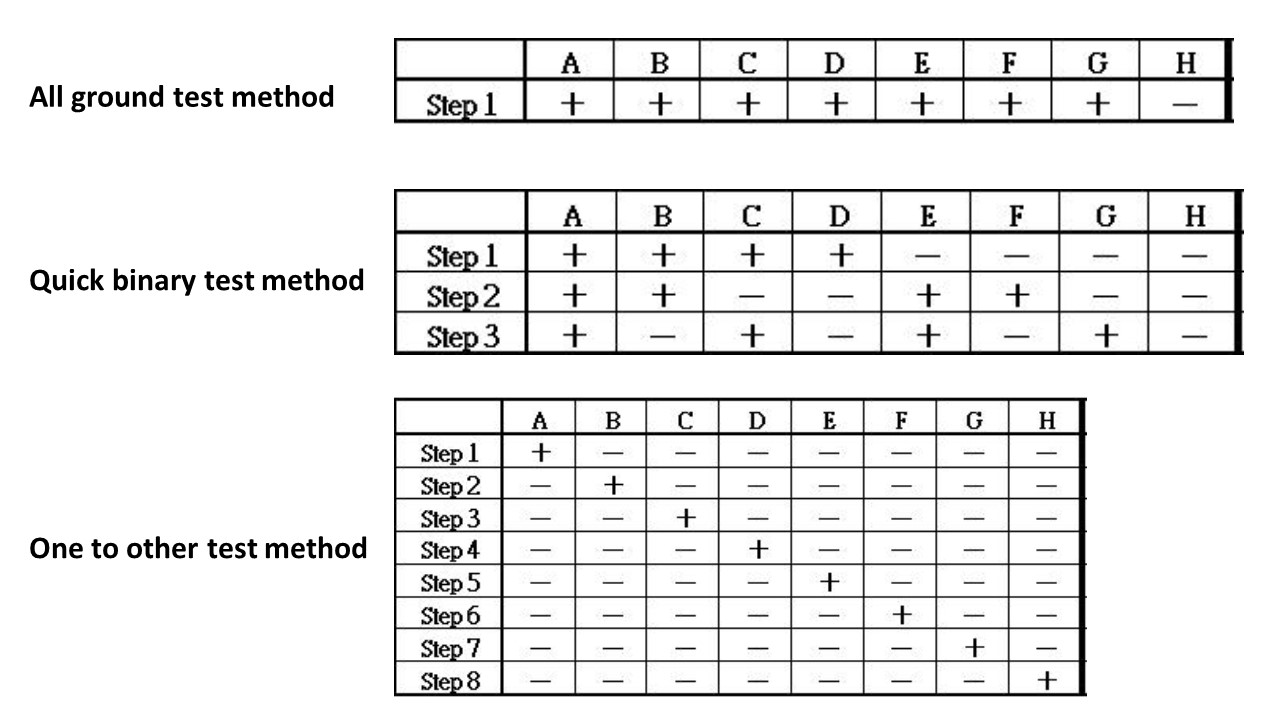

All ground test method:

- Ground pin must be set for this mode to perform insulation test for non-grounded cable to specified grounded cable; its advantage is that the test speed is fast, but its disadvantage is that insulation test is not performed between non-grounded cables.

Quick binary test method:

- This mode is similar to quick categorization; if there are 8 test pins test DUT A B C D E F G H, when test is performed for each cable or pin, it has to be tested 7 times sequentially in order to determine whether the test DUT passed. But if the quick test method is used, the first time A B C D and E F G H are divided into two groups for testing, and the second time A B E F and C D G H are divided into two groups for testing, and the third time A C E G and B D F H are divided into two groups for testing, then the test only needs to be performed three times to confirm whether the test DUT passed.

- Therefore, if the test DUT has 128 pins, and if test is performed for every cable or pin, the test has to be performed 127 times; with the quick test method, the test only has to run 8 times. However, the disadvantage is that it cannot find out which are the error pins and the cable segment resistance will be slightly lower than the actual value because of the cable segments were tested in parallel.

One to other test method:

- This is the most fundamental test method for high voltage insulation test. High voltage is connected to the test pin A and the other pins are grounded to observe its current leakage or insulation value, and then high voltage is connected to test pin B and the other pins are grounded to observe its current 60 leakage or insulation value and so on.

- High voltage is connected to each pin while other pins are grounded to observe their current leakage or insulation value. This way it can confirm that all the test pin high voltage insulation test have no problems, and the number of tests for this method is N-1 times. This test method is more accurate and it can find the insulation and current leakage value for each pin; its disadvantage is that it is slower.

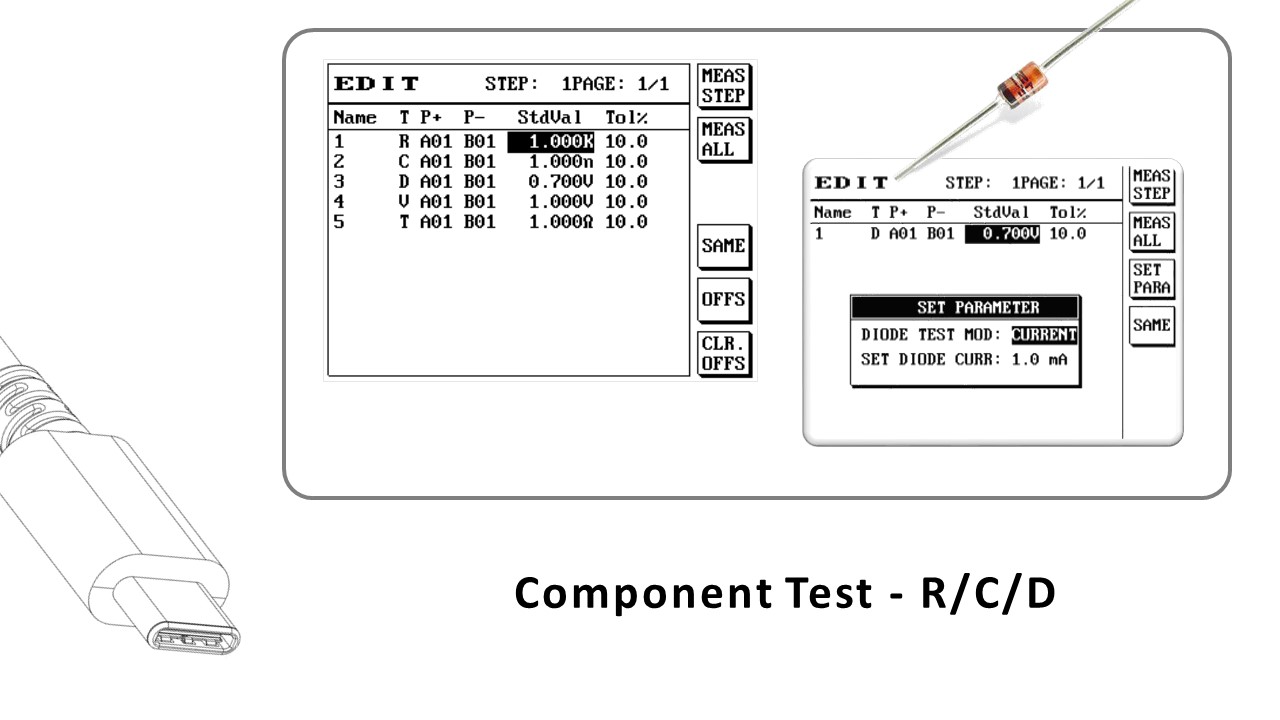

Component test - R/C/D:

- Resistance test

- Capacitance test

- Diode test.

Technical specifications of 4-Wire cable harness tester MICROTEST 8761K series

|

8761K Series |

||

|

Model |

8761NAK |

8761NK |

|

AC Hi pot Test |

100V-700V |

– |

|

DC Hi pot Test |

50V-1000V |

50V-1000V |

|

Test Pin |

512 |

|

|

Safety Hi pot Test |

||

|

AC Hipot Leakage Current |

0.01mA -5mA |

|

|

AC Arcing Detection |

Jan-48 |

|

|

DC Hipot Leakage Current |

0.1µA-1000µA |

|

|

DC Arcing Detection |

0-9 |

|

|

DC Hipot Insulation Resistance |

1MΩ-1.2GΩ |

|

|

Hipot Output Accuracy |

±5% |

|

|

Hipot Measurement Accuracy |

±5% |

|

|

Rated Output |

5Vdc |

|

|

Hipot Measurement Time |

0.01second – 60second |

|

|

Wire Specifications |

Maximum allowable capacitance 5μF |

|

|

Low Voltage Electrical Test |

||

|

Measuring Mode |

4-Wire Test |

|

|

Conductance |

1mΩ-52Ω |

|

|

Intermittence Conductance |

1mΩ-52Ω |

|

|

O/S |

1kΩ-100kΩ |

|

|

Low resistance Scanning |

Measurement Range |

10mΩ-52Ω |

|

Current Signal |

10mA |

|

|

O/S Determinal Judge |

● |

|

|

Single-Side Test |

● |

|

|

Component test |

||

|

Resistance |

Measurement Range |

50mΩ-20MΩ |

|

Level Signal |

0.5-3V |

|

|

Current Signal |

10mA |

|

|

Capacitance |

Measurement Range |

10pF-12µF |

|

Level Signal |

0.3V-1.2V |

|

|

Frequency Signal |

AUTO Gear (Optional) |

|

|

Diode |

Measurement Range |

0-6.8V |

|

Other Function |

||

|

Advanced Functions |

Programmable continuous test / Pin search/Auto-diagnosis |

|

|

Test Scan Mode |

Auto, Manual, External Trigger |

|

|

Measurement Signal |

Low Voltage Measurement Signal |

|

|

Panel |

System/Rapid /Edit / Function |

|

|

Indicator |

Pass/Fail HV LED red-green indicator lights / Screen Display /Sound |

|

System:

|

Operation |

Manual, Auto, Remote Control |

|

|

Built-in Storage |

Number of test file up to 500 sets |

|

|

Power Supply |

Fixed Voltage |

115/230 Vac ±10% |

|

Frequency |

60/50Hz |

|

|

Power consumption |

300VA |

|

|

Environment |

Temperature |

15℃-35℃ |

|

Humidity |

RH≦70% |

|

|

Display |

320*240 dot-matrix display |

|

|

Dimension(W*H*D) |

435x270x360 mm |

|

|

Weight |

18kg |

|

|

Interface |

RS-232, USB Host, Print, Remote |

|

No comments yet

SIGN UP FOR A CONSULTATION

Please fill in the form below and send your comments and questions to GMGA, we will respond to your email as soon as possible.

COMMIT

100% new product

COMMIT

100% refund if the product is of bad quality and not as promised

DELIVERY

Nationwide

Review 4-Wire cable harness tester MICROTEST 8761K series

There are no reviews yet.