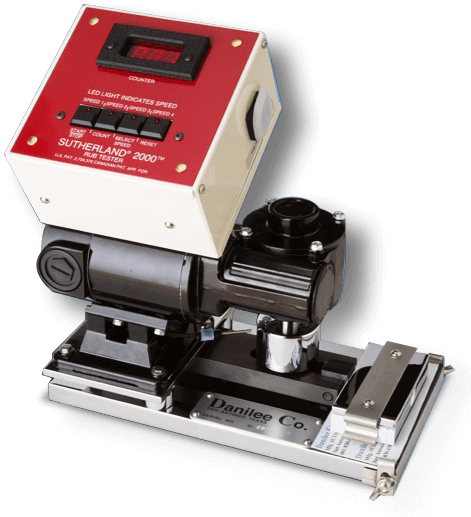

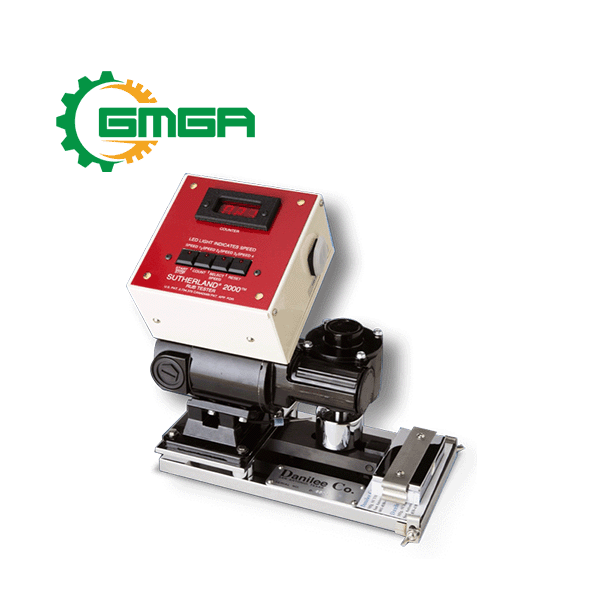

Rub tester SUTHERLAND® 2000™ 220VIRT 2000A

Price: Contact

| Model | 2000™ 220VIRT 2000A |

| Manufacturer | Danilee |

| Power supply | 220V 50/60Hz |

| Weight | 20.5 kg |

| Size | 38 x 28 x 38 cm |

| Condition | Stocking |

| Warranty | 12 months |

Rub tester SUTHERLAND® 2000™ 220VIRT 2000A from manufacturer Danilee is now offered 4 speeds allowing the customer even greater flexibility in rub tester.

The Danilee brand has an established reputation for providing an exceptionally qualified rub testing product.

I. Specification of SUTHERLAND® 2000™ 220VIRT 2000A rub tester

Description:

- Rub tester SUTHERLAND® 2000™ 220VIRT 2000A is a motor-driven abrasion testing instrument for moving a weighted test strip over a printed specimen through an arc-shaped cycle.

- The Danilee SUTHERLAND® 2000™ 220VIRT 2000A Ink Rub Tester is the industry standard for decades, has undergone some significant changes to enhance its utility and reliability. Combined with a new ASTM (American Society for Testing & Materials) recommended practice for its use, the SUTHERLAND® 2000™ 220VIRT 2000A Tester is in an excellent position to enjoy even more widespread use in the coming years.

- The result of this work is an affordable abrasion-testing instrument that retains all the features that made SUTHERLAND® 2000™ 220VIRT 2000A an industry standard plus improvements that ensure it will remain the industry standard in the new millennium.

Improvement and Recognition per ASTM D-5264:

|

|

Technical characteristics:

- The SUTHERLAND® 2000™ motor now has four speeds¹; the first speed (21 cycles per minute) is half the speed of the older models; which will make the “wet” tests, and tests using under 5 strokes easier to perform. The second speed (42 cycles per minute) and third speed (85 cycles per minute) are the same as the older models, while the fourth speed (106 cycles per minute) is faster. These new improvements allow the customer the ability to customize the testing procedure to their individual product, yet maintain the ability of duplicating a procedure used by someone with an older model unit. The higher speeds will reduce the long test times needed for certain types of substrates (plastics, UV varnishes, printed films, etc.)

- The SUTHERLAND® 2000™ 220VIRT 2000A incorporates a digital counter with a fiber optic sensor to ensure the accuracy of the number of rubs for a given test. Simply enter the number of rubs desired and the instrument will shut off automatically after the correct number of strokes. Changes to the control board programming will now allow the unit to stay on for 60 minutes before automatically turning off the LED display. Also, after the display has turned off, pressing any button will automatically display the last number of strokes entered, allowing time to record results without having to hold down the count button and re-enter the strokes with each test.

¹ Speeds of the SUTHERLAND® 2000 Rub Tester can be adjusted to meet the needs of the customer, or other test standard requirements such as TAPPI T830 om-11.

II. Function Buttons on SUTHERLAND® 2000™ 220VIRT 2000A

1.

Plug in the power cord to the correct voltage, the display will read a version number such as 1-0. If the machine is already plugged in, touching any key will reactivate the display to whatever the previous setting was. For all speed 1, low count rub tests, cycle instrument one time (001) to allow the instrument to reset for exact stroke.

2. COUNT BUTTON.

Each time the COUNT button is pressed the displayed cycle counts will increase by one. When the COUNT button is held down, the count will increase each ½ second. When the count reaches 10, it will start incrementing by 10's. When the count reaches 100, it will start incrementing by 100's. Anytime the button is released, the process will start over (i.e. ones, tens, hundreds). While the motor is running the COUNT button is deactivated and “count” adjustments can not be made. Maximum count is 999. Press “Reset” to remove the count number readout. If the motor is running, pressing reset will also stop the motor and remove the count number to 000.

Note: When adjusting the cycle count, the displayed value in the starting point, not the cycle count previously set. If the cycle count is 100 and the motor is started and then stopped at 95, pressing the COUNT button will set the cycle to 96 (replacing the previously set “count” number).

3. START / STOP BUTTON.

This controls the starting and stopping of the motor. After the count has reached 000, the motor will stop and after a short delay the display will reset back to the number that was displayed at the time of the last start cycle. If the motor is running when the START/STOP button is pressed, the motor will stop.

The display is not cleared. Pressing START/STOP will start the motor again and the count will continue from the point at which the motor was stopped.

4. MOTOR SPEED BUTTON.

Pressing the SPEED button will increment the motor through speeds 1 – 4. The speed is indicated by one of the four LED lights above the buttons. The speeds available for testing are: Speed 1 (21 cycles per minute), Speed 2 (42 cycles per minute), Speed 3 (85 cycles per minute), and Speed 4 (106 cycles per minute). When the machine is first plugged in it will automatically default to slow speed (i.e.Speed 1) unless you press the SPEED button. The motor's speed may be changed at any time, before starting the motor or after it is running. The speed of the motor is retained when the “Reset” button is pressed, to change the speed you must press the SPEED button.

5. RESET BUTTON.

This button will reset the count of the board. When pressed, the display will reset to 000. If the motor is running, the motor will shut off. This button may be pressed at any time.

When the rub has bee completed, examine both the test strips for signs of transfer. The two pieces should be stapled together and used for visual reference and interpretation. They should be marked plainly with the number of rubs (cycles) given. Place the test block on its side after using: do not place it on the machine or lay it on the rubber base.

III. Applications of Rub tester SUTHERLAND® 2000™ 220VIRT 2000A

Although the Danilee SUTHERLAND® 2000™ 220VIRT 2000A Ink Rub Tester was originally designed to fill a need for testing the scuffing or rubbing resistance of inks used in the paper and paper-board industries.However, today it is being used by manufacturers of cleaning compounds, waxes, floor tile, film, and many other items. The test results are reproducible.

The following tests may be made with the instrument:

A. Dry Rub

B. Wet Rub

C. Wet Bleed or Transfer

D. Wet Smear

E. Functional Rub.

IV. Optional Heated Weight ~ Designed for use with the Rub tester SUTHERLAND® 2000™ 220VIRT 2000A

This heated weight provides a uniform test for evaluating the “hot abrasion” resistance of printed cartons, labels, etc. Where required, rub resistance specifications may now be based on number of strokes at a given temperature as well as pressure. (refer to “Notes on the SUTHERLAND® 2000™ 220VIRT 2000A Heated Weight & Suggested Procedures...”)

Technical specifications of Rub tester SUTHERLAND® 2000™ 220VIRT 2000A

|

PRECISION ACCURACY Tolerances as close as 1/1000th All weights are within +/- 3 grams. Other testers tolerances are to 10x more! |

MORE HORSEPOWER Full 1/12 H.P. rating. Our motors are never hidden Compare this to our competition |

QUALITY CONSTRUCTION Our parts are chrome-plated solid brass Stronger than steel or aluminum Every instrument is hand-crafted |

|

MARKET LIFESPAN Industry Standard for 60+ Years Original machines still in use today Optional upgrading of models available |

WIDE TEST VARIETY 21 stroke Wet Smear test 42, 85 & 106 speed strokes Custom speeds available |

HEATED WEIGHTS Solid 304 stainless steel Silicon pad included Fully adjustible temperature range. |

Please contact us for support and more detailed information!

No comments yet

SIGN UP FOR A CONSULTATION

Please fill in the form below and send your comments and questions to GMGA, we will respond to your email as soon as possible.

COMMIT

100% new product

COMMIT

100% refund if the product is of bad quality and not as promised

DELIVERY

Nationwide

Review Rub tester SUTHERLAND® 2000™ 220VIRT 2000A

There are no reviews yet.