Mobile roughness meter HOMMEL ETAMIC Waveline W5 & Waveline W10 & Waveline W15 & Waveline W40

Price: Contact

| Model | Waveline W5 / Waveline W10 / Waveline W15 / Waveline W40 |

| Manufacturer | Brand HOMMEL ETAMIC (a part of the JENOPTIK AG) |

| Power supply | 100-240 V AC 50/60 Hz |

| Weight | 270g / 900g |

| Size | 50 x 63 x 128 mm / 238 x 43 x 66 mm |

| Condition | Stocking |

| Warranty | 12 months |

Mobile roughness meter HOMMEL ETAMIC Waveline W5 & Waveline W10 & Waveline W15 & Waveline W40 - Mobile surface measurements in flexible use

With various probes and a large range of accessories, HOMMEL ETAMIC Waveline master the most diverse measuring tasks with ease. In terms of accuracy, they are in no way inferior to stationary measuring systems.

I. Specifications of Surface measuring machine HOMMEL ETAMIC Waveline W5 & Waveline W10 & Waveline W15 & Waveline W40

- High precision: Precise and reliable measurement.

- Versatile: Mobile and stationary measuring instruments for different measuring tasks.

- Compliant with standards: Meet the strict requirements of international standards.

- Easy to use: Intuitive state-of-the-art technology and user-friendly software.

HOMMEL ETAMIC Waveline measuring systems offer you extensive evaluation possibilities for surface measurement.

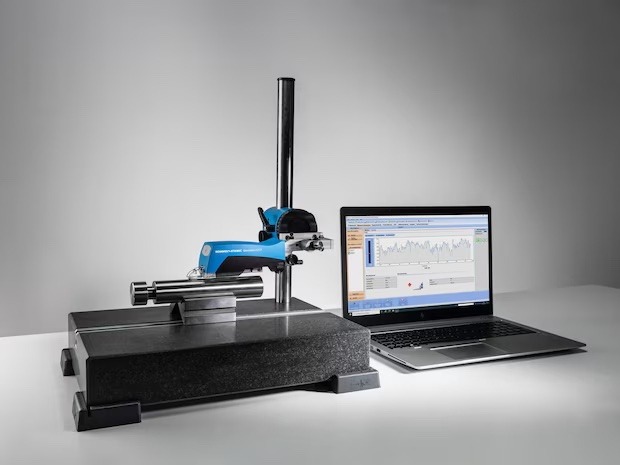

HOMMEL ETAMIC product range consists of mobile surface measuring instruments, stationary measuring systems for manual and automated

roughness, contour, topography or twist measurement, as well as combined systems for roughness and contour measurements.

Measuring stations tailored to meeting your specific measuring requirements.

II. Mobile roughness meter HOMMEL ETAMIC Waveline W5 & Waveline W10 & Waveline W15 & Waveline W40 for your applications

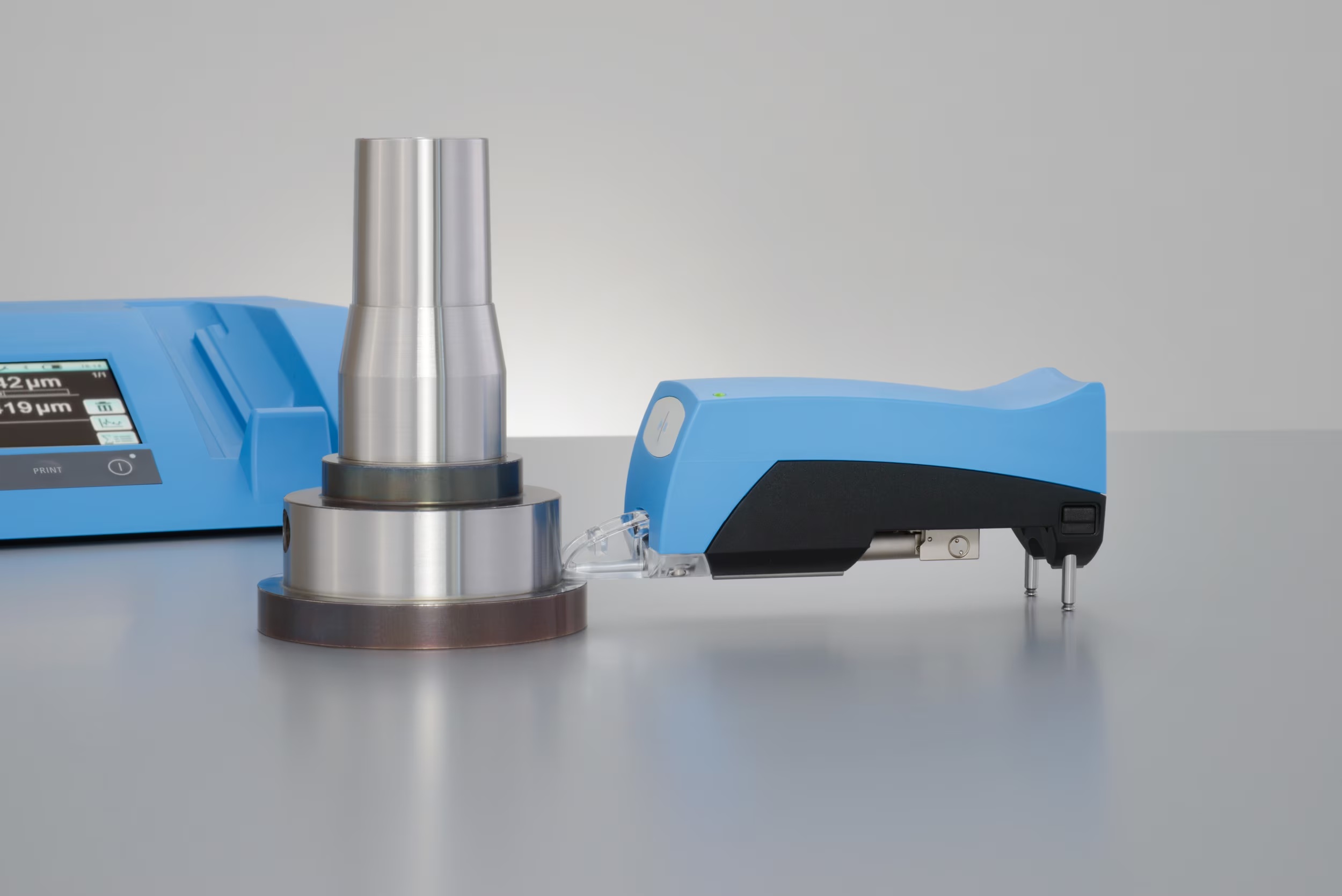

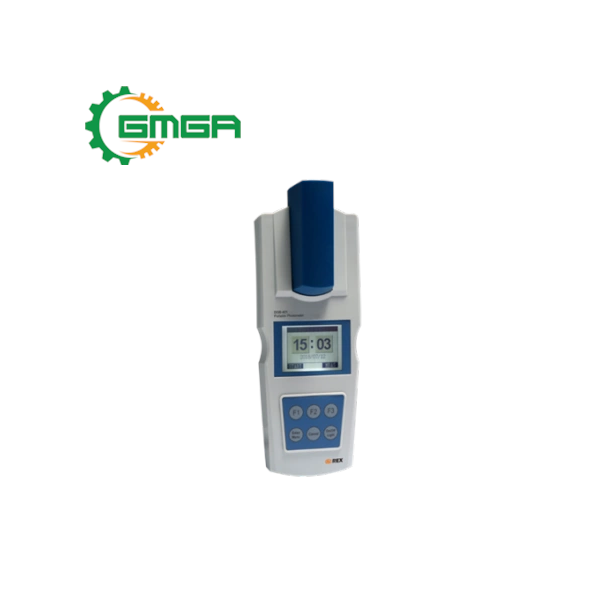

A. Waveline W5 | Lightweight, small and with long-life battery

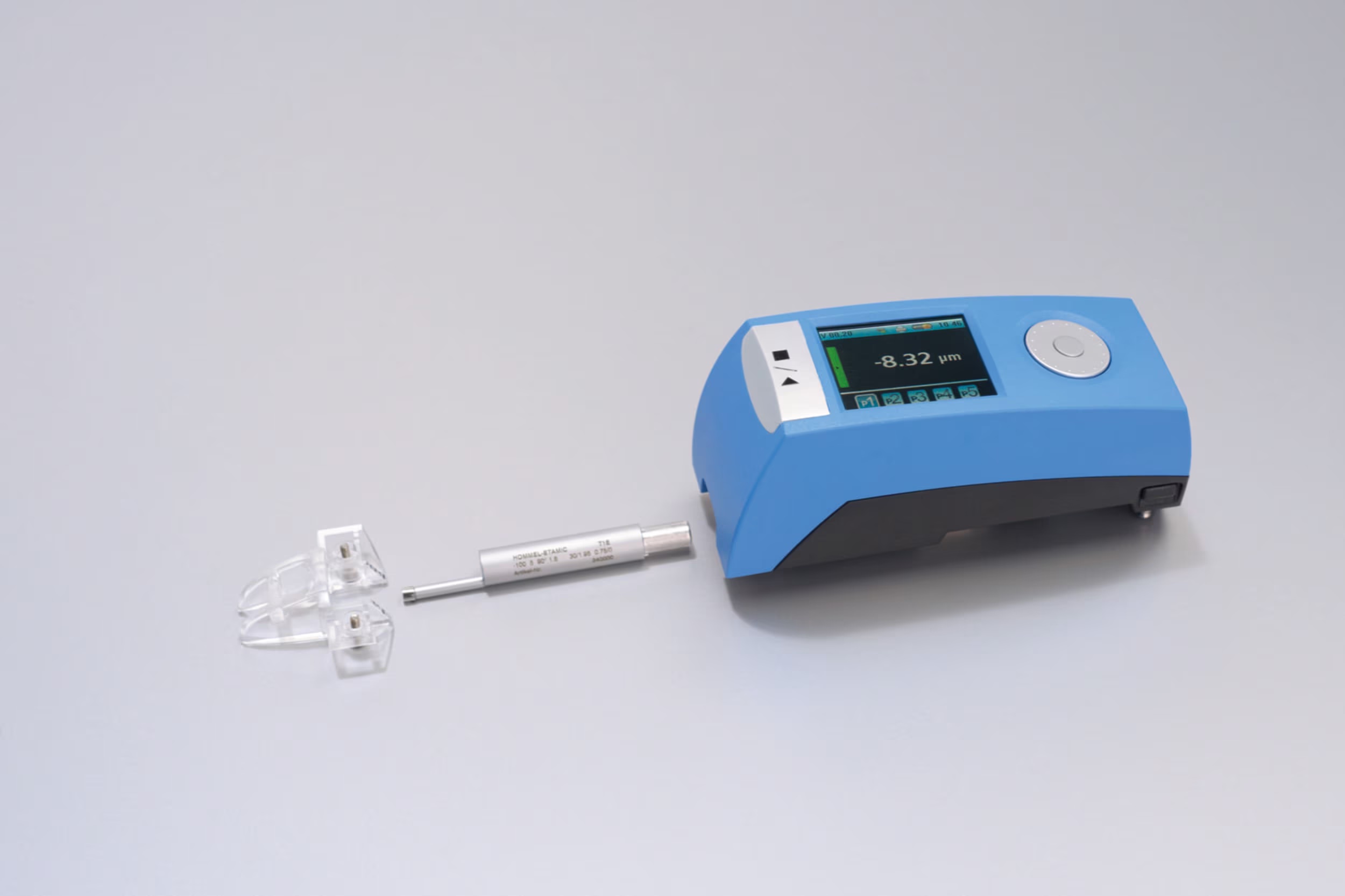

- The mobile roughness measuring device Waveline W5 convinces with safe and highly precise roughness measurement. The system is positioned precisely on the workpiece and does not slip. It weighs little and is compactly built so that you can guide it perfectly in mobile use. What's more, the rechargeable battery won't let you down even with frequent use: One charge is enough for more than 800 measurements.

- The roughness probes can be changed easily and quickly, meaning the W5 can be used for countless different measuring tasks as required. The intuitive click wheel and color display ensure that you can operate the mobile roughness measuring device particularly easily.

- As an option, you can expand the measuring system with the Waveline P5 printer. The two components are easily connected via Bluetooth® technology. This allows you to print out your measurement results directly on site without the need for any additional connection cables.

System features:

- Portable and battery-supplied

- Compact and light in design

- Easy, intuitive handling with click wheel and graphical user interface

- No calibration necessary

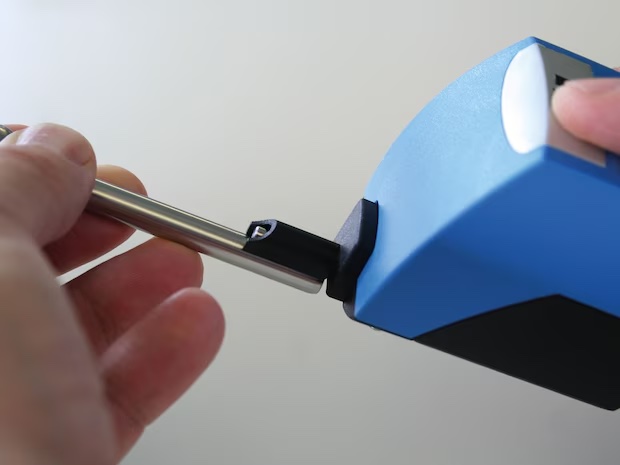

- Easily exchangeable probes

- USB port with Windows-compatible data format and battery charging function

- Features Bluetooth® technology for wireless data transfer and printing

- Battery capacity for up to 800 measurements

- Storage capacity for 5 measuring programs with measuring conditions

- Optional printer P5 with Bluetooth® technology for documentation of the measurement results on the spot

- Tolerance evaluation at a glance for immediate assessment of the measurement results

- Precise workpiece support, even on small shafts

- Measurement in all possible measuring positions, including on perpendicular surfaces and overhead.

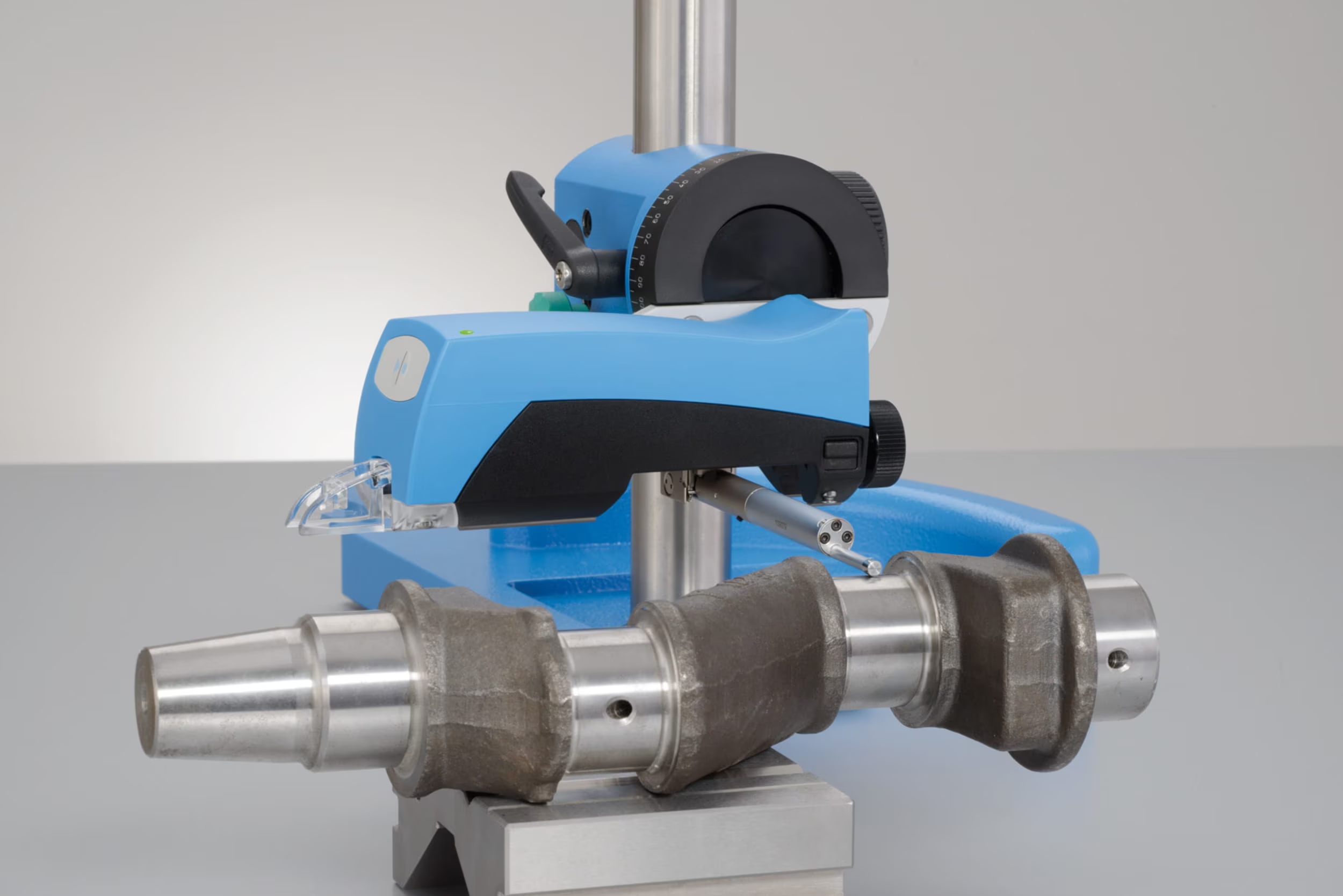

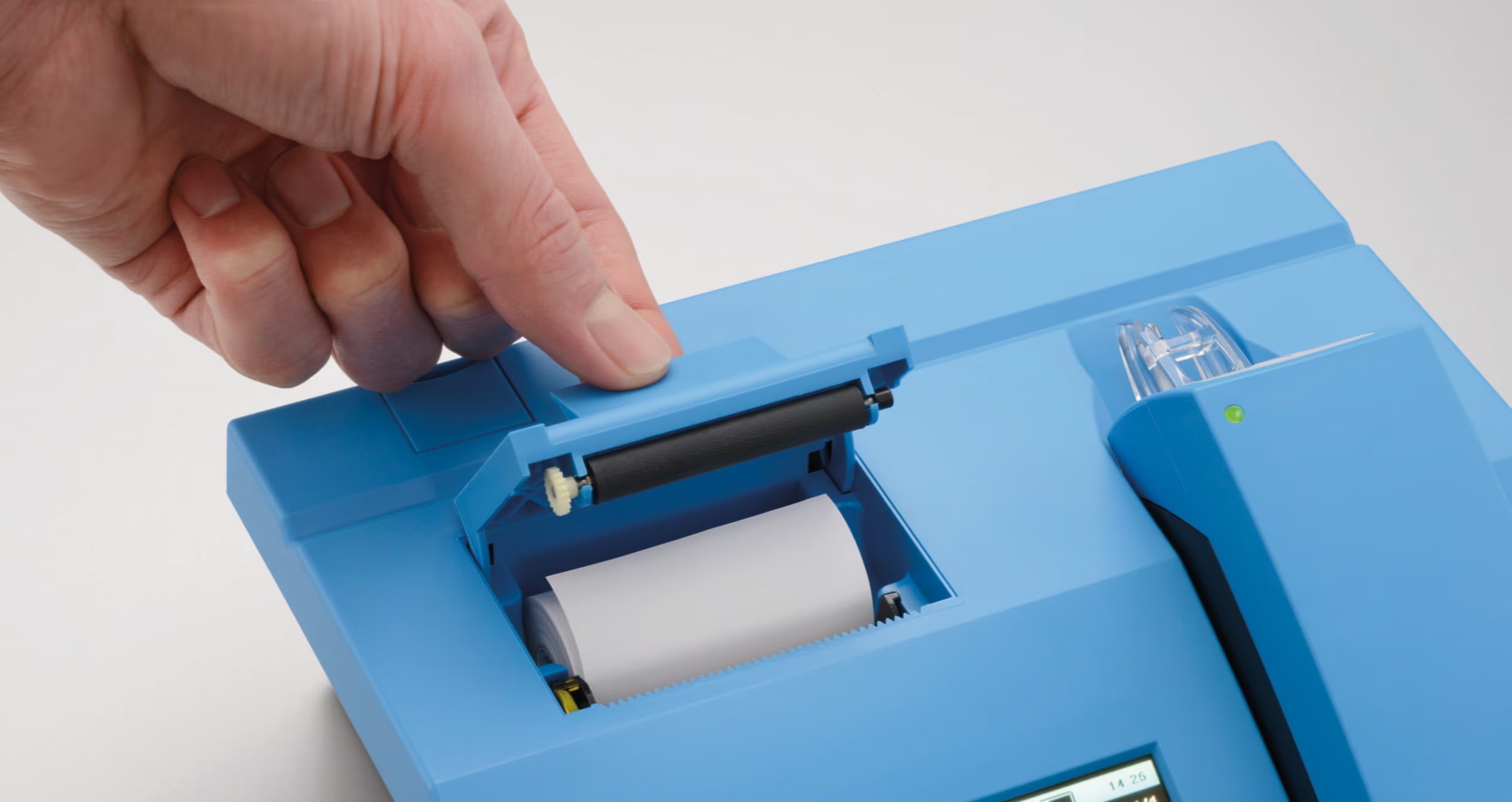

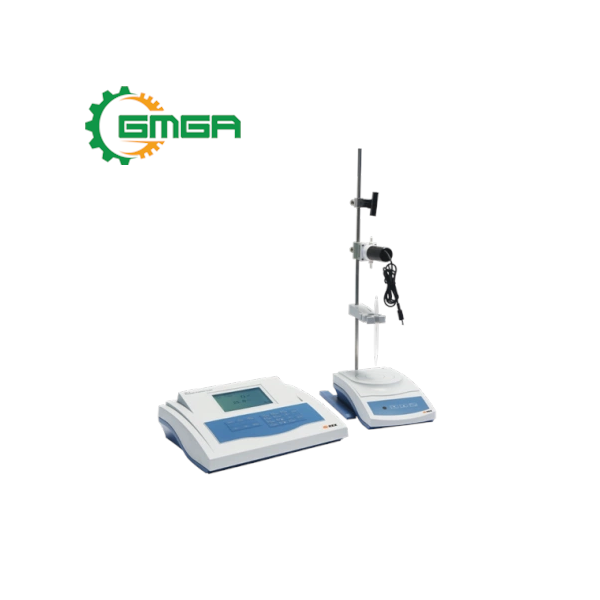

B. Waveline W10 | Mobile roughness tester with integrated printer

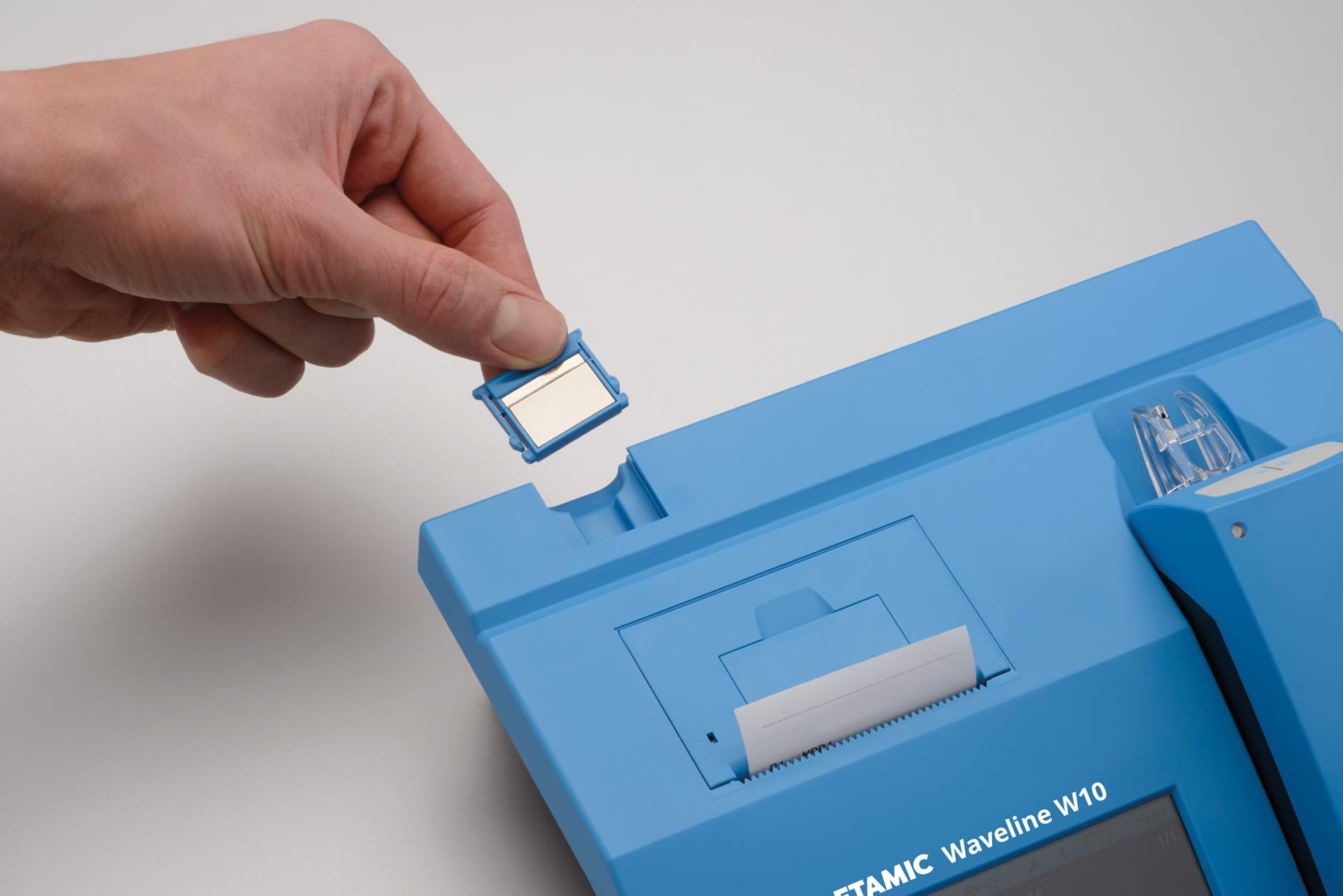

- The Waveline W10 measuring device is ideally suited for mobile roughness measurement. It allows you to monitor the surface quality of your workpieces directly in production. The handy measuring system has extensive functions. It offers reliable and precise measurement both during traverse probing and in overhead and vertical positions. The integrated roughness standard is used to quickly check the device and thus ensures consistently high measuring accuracies.

- A thermal printer is integrated in the W10. This makes it possible to document the measurement results immediately. Tolerance evaluations, profiles, Abbott curves and statistics can be printed out straight away. The measuring device offers you seven different programs as well as the option to test the instrument. All functions can be operated in a user-friendly manner via the modern color touchscreen. No time-intensive training is required, which saves you time and money.

- Optionally, you can extend the measuring system with the Evovis Mobile evaluation software. This was specifically developed for mobile measuring devices, is PC-based and considerably expands the roughness measurement functions. It works in online and offline mode and supports you in selecting the measurement conditions. It also automatically saves your print forms.

System features:

- Mobile and cable-free traverse unit LV17

- Usable as stationary instrument

- Measurement of all common roughness parameters according to international standards

- Modern, intuitive operation via color touchscreen

- Integrated rest and barrel jack for secure storage and continuous operational readiness of the traverse unit

- Immediate verification of the measuring system via the integrated roughness standard

- Easy changing of the skid probes

- Wireless data transfer via Bluetooth® interface

- Integrated printer for documentation of the measurement results on the spot

- Storage capacity for 7 measuring programs

- Measuring program specifically for verification of the measuring instrument with predefined nominal values

- 90° tilting of the probe for measurements in grooves and incisions or between collars

- Transverse probing without conversion

- Measurement of small workpieces in overhead position

- Contact to the workpiece via precisely polished shafts

- 3-point support on the traverse unit for secure positioning when measuring perpendicular surfaces

- Extendable tripod legs for height adjustment.

C. Waveline W15 | Mobile roughness meter with professional evaluation

- With the compact Waveline W15 set, you can measure surface roughness flexibly at the desired location. The handy traverse unit lies securely on the workpiece thanks to the integrated support prism and ensures precise measurements.

- The extendable tripod legs and a 3-point support on the traverse unit make it easy to adjust to the desired measuring position, both horizontally and vertically. For measurements on low-lying surfaces, in grooves, in incisions or between collars, the probe can also be swiveled by 90° without any retooling. With a wide range of skid probes, the Waveline W15 set is ready for all common roughness measurement tasks. As an option, the system can easily be extended to create a compact measuring station for production or the measuring room.

- Measurement and evaluation are carried out using the PC-controlled Evovis Mobile Standard software. The clear presentation of the measurement results, the export of parameters and profiles, optional statistical interfaces and various printout and storage options ensure user-friendly evaluation.

System features:

- Handy and cable-free traverse unit LV17 for various measuring tasks

- Integrated start button for one-handed operation

- Wireless data transfer via Bluetooth® interface

- Optional height measuring stand HS300 for measuring tasks that require precise positioning

- Optional compact measuring station MS300 for stationary use in production or in the metrology lab

- Solves all common roughness measurement tasks

- Measurement in all positions, even overhead

- Various measuring speeds

- PC-based evaluation with Evovis Mobile Standard

- All current standards including the new ISO 21920 series of standards

- Flexible program design and logging

- Export of parameters and profiles, optional statistical interfaces

- Large range of skid probes.

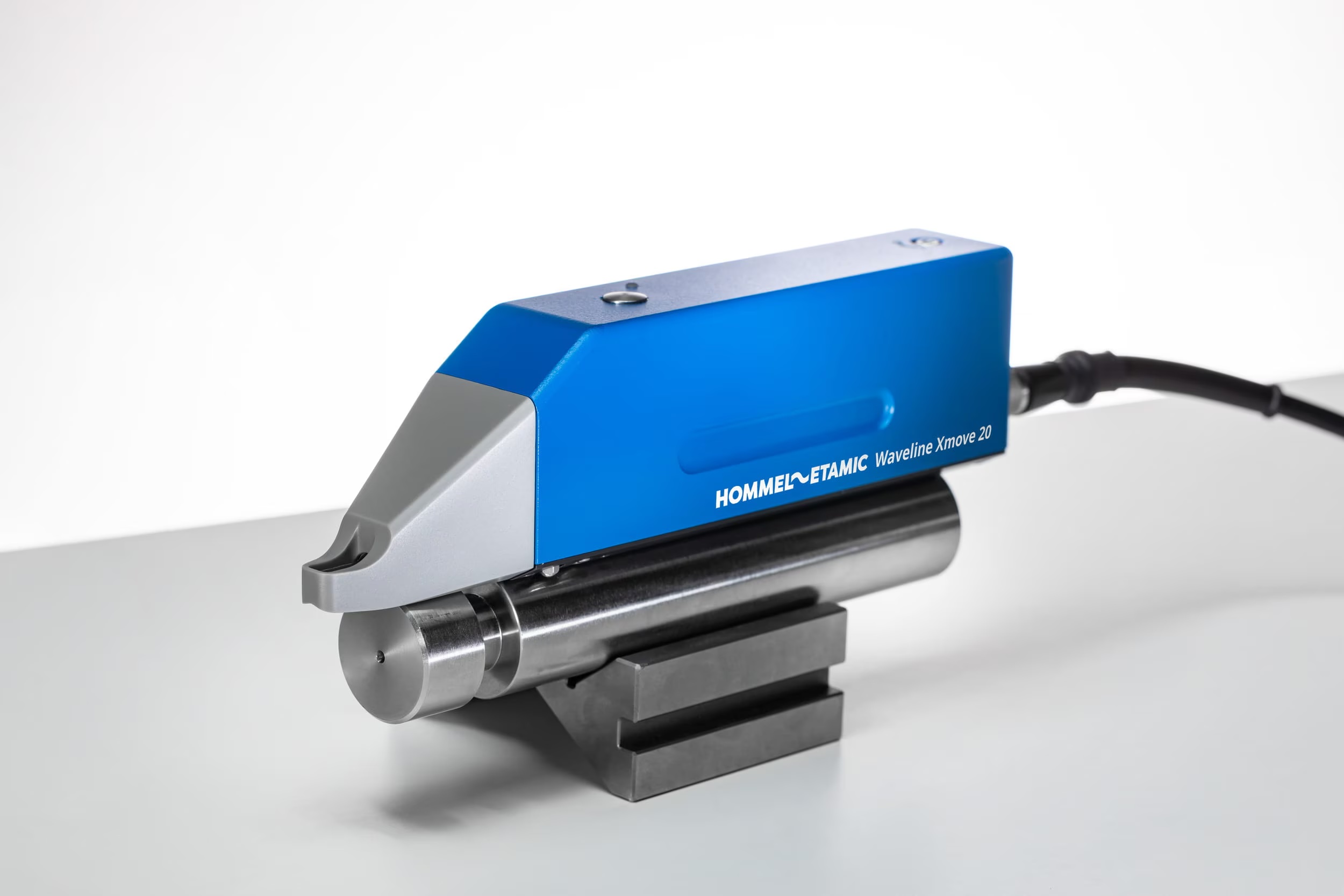

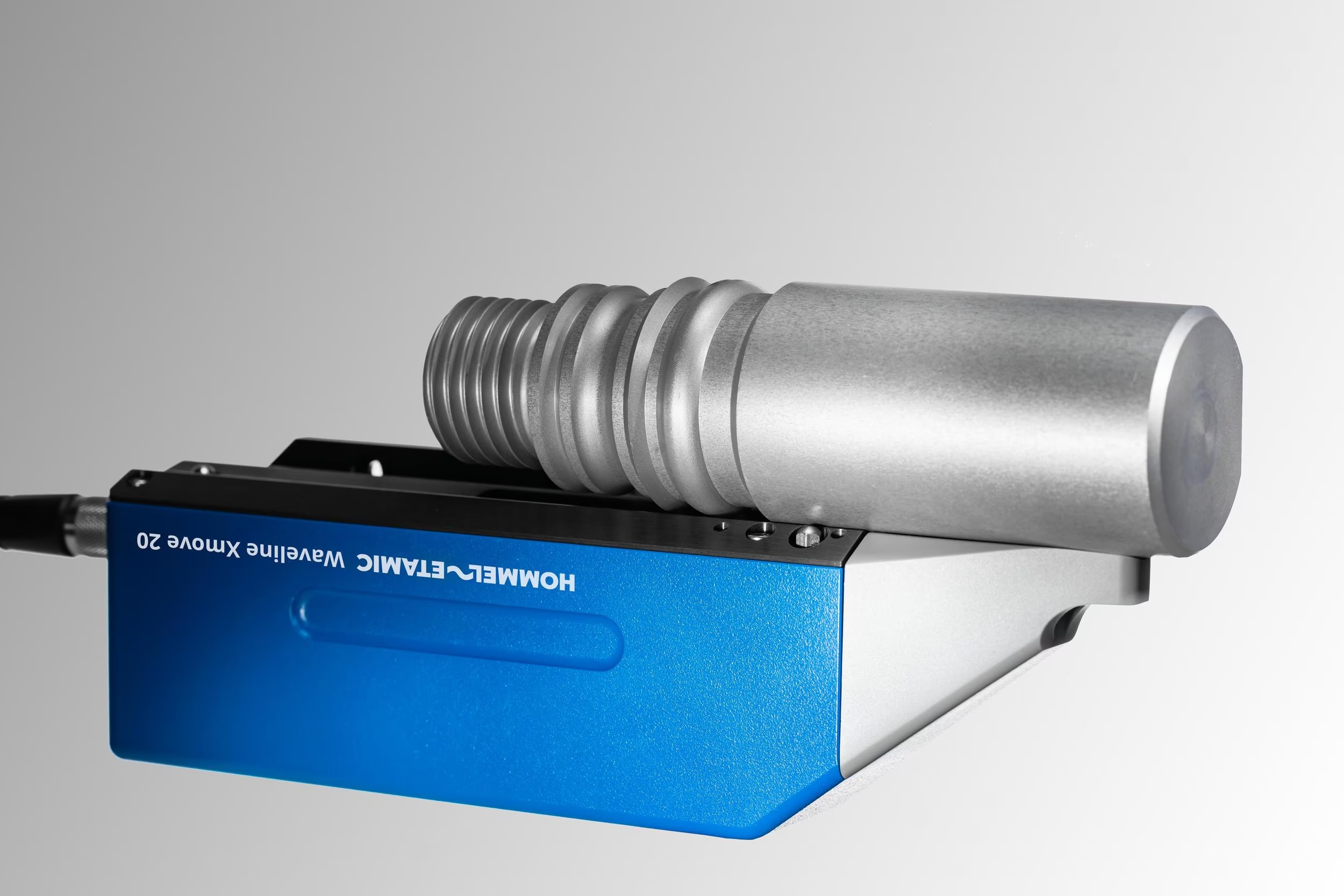

D. Waveline W40 | Flexible surface measurement with free probe system

- With its handy Waveline Xmove 20 traverse unit, the Waveline W40 set offers flexible options for measuring all common roughness, waviness and profile parameters. Operation is simple and intuitive thanks to the integrated start button and motorized probe lowering for automatic positioning of the probe.

- The traverse unit masters measurements in all positions and orientations with ease - even overhead with the probes provided for this purpose. It can be optionally used in a compact measuring station or placed directly on a large workpiece for measurement.

- Measurement and evaluation are carried out using the PC-controlled Evovis Mobile Standard software. The clear presentation of the measurement results, the export of parameters and profiles, optional statistical interfaces and various printout and storage options ensure user-friendly evaluation.

System features:

- Handy traverse unit Xmove 20 for a wide range of different measuring tasks

- Integrated start button for one-handed operation

- Optional, compact measuring station, can be used in the measuring room or in production

- Optional height measuring stand HS300 with tilting device for precise probe positioning

- Solves all common roughness, waviness and profile measurement tasks

- Supports reference plane and skid probes

- Large range of probes

- Motorized probe lowering for automatic positioning and positioning and lifting after measurement

- Measurement in all positions and orientations, including upwards (depending on probe)

- Variable measuring speed

- PC-based evaluation with Evovis Mobile Standard

- All current standards including the new ISO 21920 series of standards

- Flexible program design and logging

- Export of characteristic values and profiles, optional statistical interfaces.

III. Evovis Mobile software: Simple evaluation and operation of mobile measuring instruments

- The Evovis Mobile software is specifically designed for operation with mobile measuring devices and small measuring stations. In online mode, the mobile measuring device is controlled directly by the software. Parameters and profile data recorded with the Waveline W5 or W10 can be transferred to the software and evaluated centrally.

- Evovis Mobile is available in Standard and Advanced versions.

System features Evovis Mobile Standard:

- Clear, user-friendly operating structure

- All common roughness and waviness parameters in accordance with ISO 21920, ISO 4287 and other ISO and national standards (ASME, DIN, JIS, Motif, etc.)

- Continuous further development of the software in line with new standards/changes in standards

- Import and subsequent processing of profiles and parameters

- Individual test plan creation

- Integrated help with the parameters

- Wizard for selecting the measuring conditions

- Open design of the print log

- Electronic archiving of reports via PDF printout

- Optional qs-STAT® data export interface

- Optional evaluation of dominant waviness according to VDA 2007.

Additional features Evovis Mobile Advanced:

- Management of several measuring points in one test plan

- Control of measurement sequences via CNC function.

No comments yet

SIGN UP FOR A CONSULTATION

Please fill in the form below and send your comments and questions to GMGA, we will respond to your email as soon as possible.

COMMIT

100% new product

COMMIT

100% refund if the product is of bad quality and not as promised

DELIVERY

Nationwide

Review Mobile roughness meter HOMMEL ETAMIC Waveline W5 & Waveline W10 & Waveline W15 & Waveline W40

There are no reviews yet.