Home » Products » Measuring Equipment » Hardness measuring equipment » Benchtop hardness tester » Rockwell hardness tester NOVOTEST TB-RC

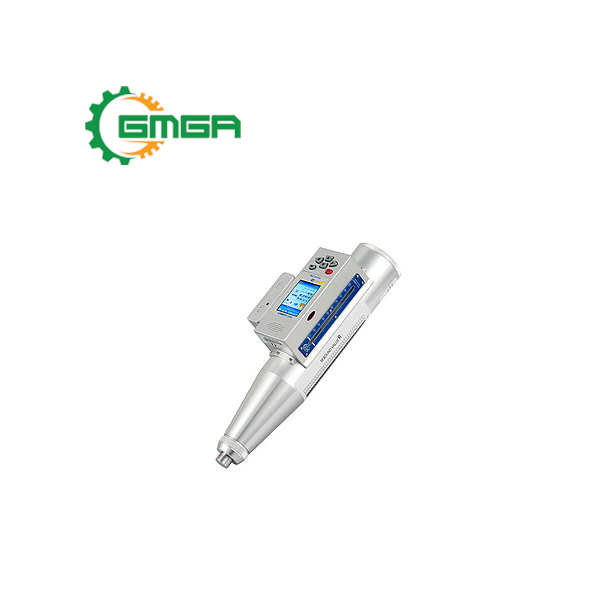

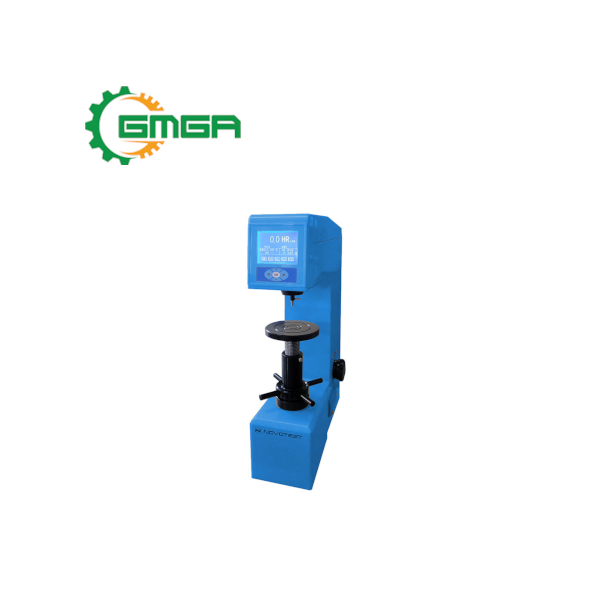

Rockwell hardness tester NOVOTEST TB-RC

Price: Liên hệ

| Model | TB-RC |

| Manufacturer | NOVOTEST |

| Power supply | |

| Weight | |

| Size | |

| Condition | Còn hàng |

| Warranty | 12 tháng |

I. Specification Rockwell hardness tester NOVOTEST TB-RC

- The NOVOTEST TB-RC Digital Hardness Tester is a digital model with a newly designed large LCD screen to show the structure of the menu.

- The Rockwell NOVOTEST TB-RC Hardness Tester features a super RS-232 terminal with good reliability, great performance and easy viewing.

- The Rockwell TB-RC hardness test uses the indentation depth method. The hardness values are read directly through the LCD display. Therefore, it is easy to operate the hardness tester with high efficiency.

- This Rockwell NOVOTEST TB-RC hardness tester is suitable for testing parts batches. The Rockwell NOVOTEST TB-RC Digital Hardness Tester allows the use of diamond and ball tools, which can measure hardness and soft specimens. Therefore, it has been widely used in production to become the most detection equipment for checking product quality and determining reasonable processing technology.

- The NOVOTEST TB-R-C Digital Rockwell Hardness Tester performs Rockwell's Direct Hardness Test method according to ISO 6508-2 and ASTM E18.

II. Application

- The NOVOTEST TB-RC hardness tester allows users to measure the hardness of:

- Hardened and surface hardened steel, hardened and tempered steel;

- Cold and hard molded parts, forged parts;

- Hard alloy steel;

- Aluminum alloy;

- Bearing steel;

- Carbonized steel plate and others.

III. Standard package

- Rockwell hardness tester NOVOTEST TB-RC

- Rockwell Cone Diamond Tool (120°)

- Clear polished Rockwell hard alloy steel (d = 1.5875 mm)

- Large test board (150 mm)

- Medium test panel (60 mm)

- V-shaped lab table

- Rockwell hardness test block (5 pieces in total):

- HRA: 85 ± 5 - 1 cái.

- HRB: 90 ± 5 - 1 cái.

- HRC: 65 ± 5 - 1 cái.

- HRC: 45 ± 10 - 1 cái.

- HRC: 25 ± 5 - 1 cái.

- RS-232 interface

- Bolt adjuster (4 pcs.)

- Power cable

- Fuse (2 pieces.)

- Operating manual

- Certificate of Calibration

- Shipping Box.

IV. Specifications of Rockwell hardness tester NOVOTEST TB-RC

| Indenter | Conical Rockwell diamond indenter (120 °): diamond tip as a cone with 120 degrees of the cone apex angle and the bead size of 1/16 inch (1.5875 mm) |

| Scales |

20-88 HRA |

|

20-100 HRB |

|

|

20-70 HRC |

|

|

40-77 HRD |

|

|

70-100 HRE |

|

|

30-94 HRG |

|

|

80-100 HRH |

|

|

40-100 HRK |

|

| Hardness resolution value |

0.1 |

|

Measurement accuracy |

<1.0% |

| Conversion scales |

Plastic Rockwell, Brinell, Vickers |

|

Initial testing load(accuracy ±2%) |

98,07N (10kg) |

| Testing load (accuracy ±1%) |

588,4N (60kg) |

|

980,7N (100kg) |

|

|

1471N (150kg) |

|

|

Measuring time |

5~60 sec |

| Testing materials |

Cemented carbides, thin steel and shallow case hardened steel |

|

Steel, hard cast irons, pearltic malleable iron, titanium, deep case hardened steel & other material harder than HRB 100 |

|

|

Thin steel and medium case hardened steel and pearlitic malleable iron |

|

|

Hardened and surface hardened steel, hardened and tempered steel; cold and hard casted parts, forged parts; hard alloy steel; aluminum alloys; bearing steel; carbonized steel sheets and others |

|

| Max height of test sample |

100 mm (210 mm – without protective cover) |

|

(can be produced up to 400 mm) |

|

| Max depth of test sample |

165 mm |

|

Power supply |

220V±5%, 50~60Hz |

| Data output |

LCD |

|

Built-in printer |

|

|

RS-232 interface |

|

|

Recommended operating conditions |

Air temperature: 0…+40 °С |

|

Air pressure: 94 – 106.7 kPa |

|

|

Humidity: up to 65% |

|

| Net weight |

86 kg |

|

Gross weight |

96 kg |

| Package dimensions |

630*500*860 mm (L*W*H) |

No comments yet

SIGN UP FOR A CONSULTATION

Please fill in the form below and send your comments and questions to GMGA, we will respond to your email as soon as possible.

COMMIT

100% new product

COMMIT

100% refund if the product is of bad quality and not as promised

DELIVERY

Nationwide

Review Rockwell hardness tester NOVOTEST TB-RC

There are no reviews yet.