AMQ540 CNC video measuring system

Price: Contact

| Model | AMQ-540 |

| Manufacturer | AUSKY |

| Power supply | AC 220V 50Hz , 110V 60Hz |

| Weight | 700 Kg |

| Size | 1090 x 820 x 1700 mm |

| Condition | Stocking |

| Warranty | 12 months |

I. Specification AMQ540 CNC video measuring system

Main features of the device:

- AMQ540 CNC video measuring system adopts high-precision granite structure, hard to deform, high stability, high-end beautiful.

- High-precision optical grid system, high-resolution color CCD.

- P-grade guide bar, high-precision transmission.

- High performance servo system, high precision, high efficiency and high stability.

- Adjustable LED light source zone, allowing multi-directional projection.

- CNC software controls the controller, Auto focus, auto zoom ratio conversion, Auto edge detection, Auto light sense, Auto measure, High efficiency assurance.

- Configured with industry leading proprietary measuring software.

- Integrated overall design.

- Configured with imported RENISHAW high precision contact type probe group. Configured with high-precision laser meter, programmable automatic coaxial composite image/probe/laser.

Structure of the device:

- This AMQ540 CNC video measuring system is designed with marble table base and cantilever mechanism, the instrument is featured by stable accuracy, good adaptability to working environment , simple, robust, never deformation and beautiful body structure and ergonomics designed operating mechanism, and equipped with powerful measuring software and easy to operate.

Movement mechanism:

- This image measuring instrument is provided with three-axis automatic control and equipped with imported precision optical grid system, Japan Panasonic servo high efficiency motor system, Taiwan TBI screw rod, typeface Standard and high precision V guide rails as well as professional measuring software for measuring.

Advantages with automatic measuring instruments:

- AMQ540 CNC Video Inspection Gauge can avoid human error for "Machinable Object" by manual measurement, and also can avoid secondary damage caused to "Workpiece" by measuring manual, with guaranteed mass stability and object criterion consistency. This tool can greatly improve detection efficiency during production, identify defects, and control failed products before they enter the production process, and can help reduce part costs for manual detection and increased timeliness of delivered product.

Scope of application:

- This image size measuring instrument can be used to measure the dimensional accuracy of the Aerospace, automobile and ship, scientific research and teaching, electronics, hardware and plastic, precision metal stamping plate, silkscreen printing plate, acrylic sheet, LCP film, board PCB, LCD\TFT, glass coating plate, TP, frame of super large LCD, die cutting, backlight module group, as well as for ancillary measurements such as graphic reverse engineering R&D, design, drawing editing, laboratory testing, etc.

Configure the main function of the device:

- CNC video measuring system AMQ540 used with professional automatic measuring software AUSKY, Aocheng special controller , MEAN WELL power supply, Panasonic servo motor drive system, TEO color 650TV CCD, PMS high resolution exceptionally high 0.7–4.5 times - definite continuous zoom and fixed focus screen optical lens, LED partition program control light source, imported high precision grating system, calculator LCD monitor keyboard, mouse and digital meter.

General achievement:

- Suitable for measuring different applications, complex dimensions and high measuring accuracy requirements, with even easy and fast measuring efficiency and improved measuring efficiency.

- This measuring instrument has the following advantages in terms of image processing: automatically skips ridges, automatically generates measurement reports and results statistics, and opens to link with printers, etc., as appropriate. for wide industry applications.

Cost savings:

- The AMQ540 Video Test Meter can achieve multiple functions on the same instrument, saving users the cost of repeated purchase of measuring equipment as well as saving on labor costs and equipment space. It can meet the needs of user enterprises for larger growth in the future and the need to rapidly expand product testing to create a solid foundation for users' quality assurance.

II. Software function

A. Multiple measurement methods

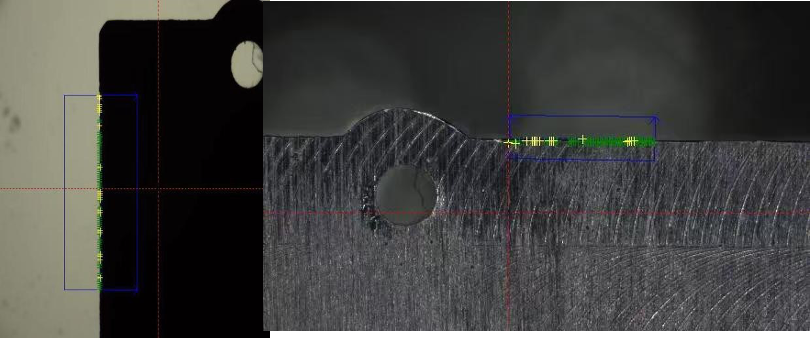

- This dimensioner includes auto edge detection, auto section edge detection, mouse screen dot fetch, diagonal pointer, asymptotic point, contrast and vertex pointer, contour pointer, pointer pointer probe, laser pointer, etc.

B. Powerful edge tracking algorithm

- Ensures sampling point accuracy and automatic pixel correction for sampling stability, where a single stroke allows automatic pixel correction, which does not need to be changed frequently.

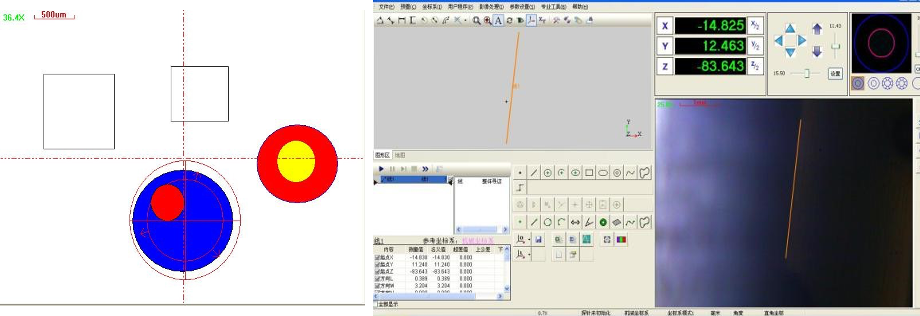

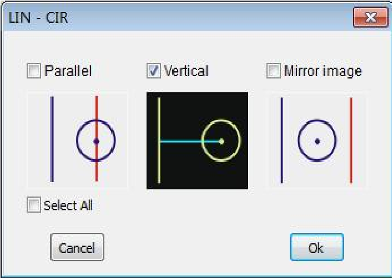

C. Element structure

- Element structure engineering, provides many methods, such as displacement, rotation, extraction, combination, parallelism, plumbing, reflection, symmetry, intersection, structured elements tangent; The element structure will allow the user to deal with some elements that are difficult to measure, thus leading to increased work efficiency; The composing process is to choose the elements to participate in the composition, to choose the resulting element, which is clear and simple. Options for composition methods are available as illustrations.

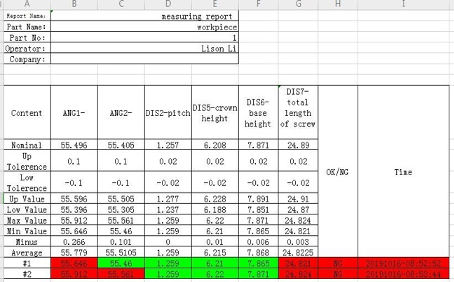

D. Rich reporting functions

- Result data export toolbar

The software supports exporting documents in EXCEL, WORD, TXT, DXF, IGS formats. The EXCEL or WORD application must be installed before you export an EXCEL or WORD document. Click the export EXCEL button and WORD will automatically start the respective application. DXF format documents are opened with Auto CAD or other graphics software. Document export toolbar as follows:

The user can set whether to output the measurement result of an element and also set whether to output an item of the element result, as shown below:

- EXCEL document export settings

Due to the diversification of EXCEL table requirements, the software supports setting EXCEL documents, click the EXCEL export settings button on the export toolbar and pop up the following dialog.

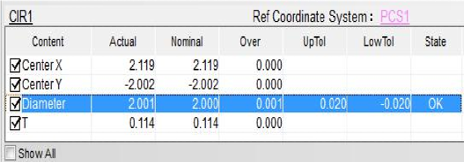

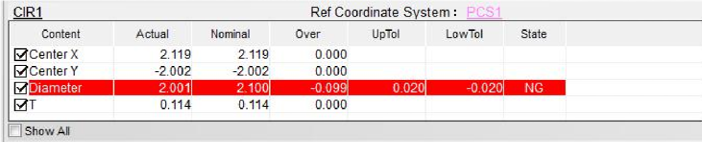

E. Warning over tolerance red

- In case the measurement result is out of tolerance, the specific element and the element composition can be displayed and the derived EXCEL can both remind which item is out of tolerance.

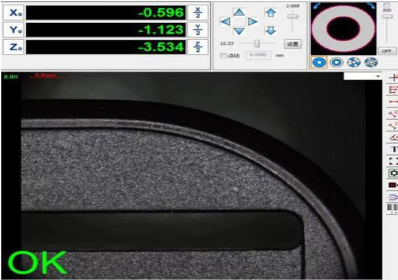

F. The rich functions of the picture window

- Can display scale and magnification ratio, and can measure distance and simple angle.

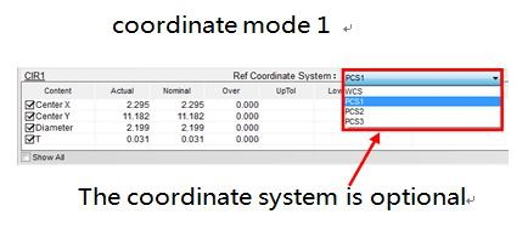

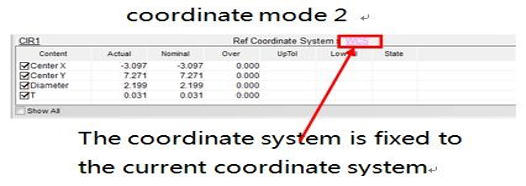

G. Rich functions of the coordinate system

- This dimensioner AMQ540 can set up multiple coordinate systems on the basis of actual conditions, can convert data flexibly according to any coordinate system, can convert conveniently between straight angle coordinate system and coordinate system. polar coordinates, can save and recall different coordinate systems, and can display different modes of coordinate systems.

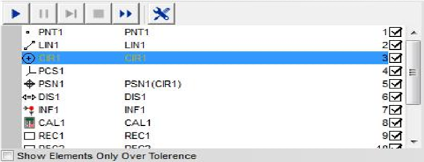

H. Convenient program editing and modification

- Allows convenient modification of light source data, kinetic data, focus data, program position, height measurement, etc., as well as being able to replace existing elements with new ones.

- I have many tolerance functions

- Wide range of geometrical dimensional and tolerance calculations available; Allowed to calculate 2D and 3D tolerances, for example, geometrical tolerances such as roundness, cylinder, alignment, plane, etc., as well as tolerances such as position, parallelism, verticality, inclination, concentricity, pulse, etc.

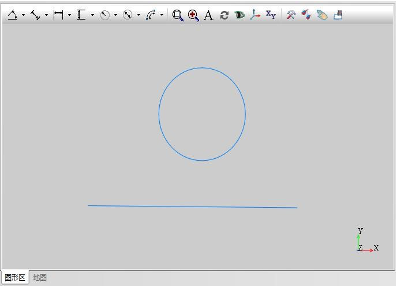

J. Map contour, scan and navigation software that provides powerful navigation functions

- The measuring device can scan the entire map by specifying the start and end points, and can also import images taken by the external sensor for navigation;

- The scan function can be used in the reverse function, can specify the start and end point of the scan, and the specially designed algorithm; allows to increase the accuracy and practicality of the scan through the filtering of impurities; allows to trace the graphic open or close to have a border

- Trace, to get the desired contour. The number of scan points can be set, on the contour and the software can automatically calculate the scanning distance.

K. Powerful tagging function

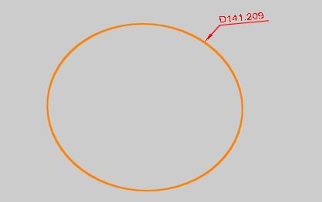

- Available in many types of tagging, e.g. Distance, Angle, X Distance, Y Distance, Radius, Diameter, Arc Length, etc., allows to change the position after finishing mounting tags, as well as auto-tagging users, that will remain after the program ends.

***Discover more dimensioners at: https://gmga.vn/en/danh-muc/measuring-device/dimension-measuring-equipment/

III. Specifications of AMQ540 CNC video measuring system

|

1 |

Model | AMQ-540 |

| 2 | Instrument Material |

High-Precision Granite Structure |

|

3 |

Machine Size(mm) | 1090X820X1700mm |

| 4 | Glass Table Size(mm) |

550X450mm |

|

5 |

Travel(mm) | X-AXI500*Y-AXIS400*Z-AXIS200mm |

| 6 | Weight(kg) |

700KG |

|

7 |

Instrument Precision(um) | X、Y(3+L/200)um |

| 8 | Light Source |

LED Programmable Partition Light Source |

|

9 |

Measurement Function |

AUSKY Software |

|

10 |

Raster Resolution | 0.0002mm |

| 11 | The Camera |

TEO Color CCD Camera |

|

12 |

Eyepiece | 1X |

| 13 | Lens |

Zoom 0.7-4.5X |

|

14 |

Total Video Magnification(X) | 30X~200X |

| 15 | Power Supply |

AC 220V 50HZ ,110V 60HZ |

|

16 |

Temperature and Humidity | Laboratory standards |

| 17 | Site |

There is no high frequency around; No vibration; No pollution, etc. |

IV. Video

***Watch more videos about CNC video measuring systems at: Gmga Measuring Youtube.

No comments yet

SIGN UP FOR A CONSULTATION

Please fill in the form below and send your comments and questions to GMGA, we will respond to your email as soon as possible.

COMMIT

100% new product

COMMIT

100% refund if the product is of bad quality and not as promised

DELIVERY

Nationwide

Review AMQ540 CNC video measuring system

There are no reviews yet.