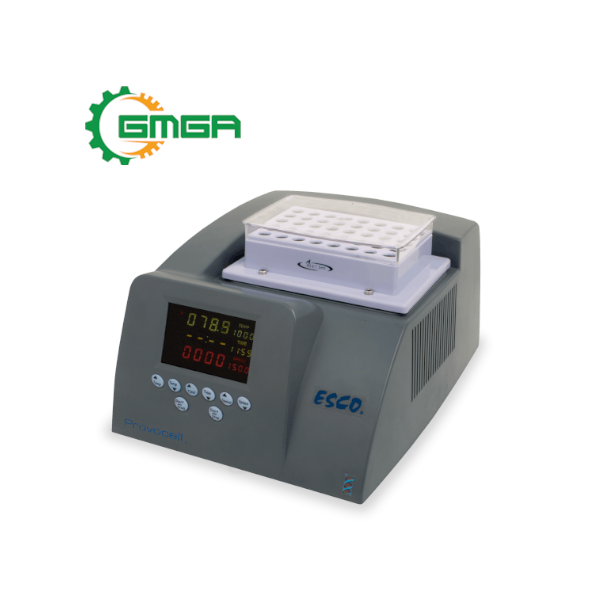

Bioreactor system Esco TideXcell ®

Price:

| Model | |

| Manufacturer | |

| Power supply | |

| Weight | |

| Size | |

| Condition | |

| Warranty |

I. Specification Esco TideXcell ® cell culture system

Tidal movements in the Esco TideXcell ® bioreactor:

[video width="600" height="400" mp4="https://gmga.vn/wp-content/uploads/2021/11/Hệ-thống-nuôi-cấy-tế-bào-Esco-TideXcell-®_01.mp4" autoplay="true"][/video]Advantages of Esco TideXcell ®:

- Adhesive cell scale for packing bed volumes up to 5,000L (bioequivalent of 50,000 L in suspension)

- 100% media exchange system ideal for continuous bioprocessing

- Separation of substrate and mixing vessel -implements dual temperature control to produce higher virus titers

- Integrated weighing platform and in-house mixer

- PLC-based monitoring Esco TideXcell® bioreactor system - with simple, intuitive touch screen running on Wonderware SCADA

- Can be connected to SCADA system by DeltaV or Pcs7 . controller

- Dual redundancy - for critical components such as PLCs and pumps provided

- Delivers massive downscaling - and reduces costs by saving vehicles, labor, space, utility, and most importantly, eliminating cross-contamination

- Isolation ability.

- cGMP Standard Reference

- PAT / IPQC.

Esco TideXcell ® - Applications:

Esco TideXcell ® - Applications:

- Culture of anchorage-dependent cells with BioNOC™

- Train series cell

- Vaccine production

- Production of recombinant proteins and monoclonal antibodies

- Biosimilars and biobetters

- Convert from 2D system to closed 3D system

- Continuous biological treatment

- Production of wild virus

- Cell therapy

- Biologic drugs for tropical diseases.

II. Highlights of Esco TideXcell ® pilot bioreactor system

Homogeneous seed:

- TideXcell ® Matrix Bed is designed to cut the area into small pieces and force the cells to flow in a radial direction instead of a vertical direction. The gradient effect in the seeding stage can be minimized.

- A matrix cassette packed with 3D-configured carriers for optimal cell growth. Paper trays are stacked inside the matrix flask (2 L, 20 L, 100L) to uniformly granulate the cells.

The principle of uniform sowing:

- TideXcell ® Matrix Bed is designed to cut the area into small pieces and force the cells to flow in a radial direction instead of a vertical direction. Gradient effect in seeding stage can be minimized.

TideXcell ® -100 packaged with matrix tray (view from above):

- This concept is achieved by packing the matrix bed with foam tapes of smaller diameter when the matrix is packed inside.

100% media exchange:

- Continuous harvesting can be done in the TideXcell system due to 100% media exchange. This process is beneficial when culturing viruses to produce higher viral titers or for stem cell cultures that require switching to a different medium for differentiation.

- Due to the separation of the platform (where cells reside) and the mixing vessel (where the mixing of cultures is taking place), the system is capable of completely collecting waste or conditioned media and feeding. in 100% fresh culture afterwards without harming the cultured cells.

Closed sampling for cell monitoring:

- Closed system sampling can be performed in the TideXcell ® system. Each type of vessel has its own corresponding number of sampling ports.

- A matrix cassette packed with 3D-configured carriers for optimal cell growth. Paper trays were stacked inside the matrix flask (2 L, 20 L, 100 L) to uniformly granulate the cells.

SCADA:

- TideXcell® based monitoring and control architecture running on WonderWare SCADA. This provides a high-level process monitoring and data collection management. This software platform will ensure process control security, will support the control strategy, and will provide a method for collecting data and remote events (alarms) for continuous process monitoring. The SCADA platform also provides functions for graphical display, alerts, trends, and historical data storage.

- TideXcell ® is at the core of Esco Aster, a contract development manufacturing organization (CDMO) that utilizes single-use adhesive bioreactors for bioremediation needs. Esco Aster focuses on process development, commercialization of new human and animal transducing (NTD) drugs, orphan drugs, as CMO for the partner factories TideXcell ® wants. outreach in ASEAN, ANZ, Africa.

Esco TideXcell ® Dimensional compare:

III. Specifications bioreactor system Esco TideXcell ®

TideXcell ® Product Specifications TideXcell ® Incubation and Control Unit |

|

|

Construction |

External Carcass: 316 stainless steel |

| Dimension |

125 (W) X 70 (D) X 115 (H) cm |

|

Weight |

240 kg |

| Electrical requirements |

AC 220V 20A, 50/60 Hz, Single phase UPS (uninterrupted power supply) width 6kVA/4.2kW should be prepared by customers |

|

Control Hardware (2-20L) |

Flexible PC-based/DAQ industrial control interface; Solenoid valves/PID gauges/Pressure-vacuum motor NDIR CO2 diffusion type sensor |

| Control Hardware (50-100 L) |

Siemens HMI/PLC based control structure Solenoid valves/PID gauges/Pressure-vacuum motor NDIR CO2 diffusion type sensor |

|

Control Software |

Siemens PLC-based control and monitoring structure Siemens HMI with 12.1" touchscreen Development environment: TIA Protal V13 SP1 |

| Incubator |

0 - 20% CO2 PID Control +8ºC~27ºC Operating Temperature Front view window; LED inside lighting Emergency power-off button |

|

Connection |

CPC nickel-coated brass quick connectors Electric connectors with locking-screw |

| Communication |

9-pin Dsub RS-485 port : Modbus RTU protocol 2 USB Ports for import firmware / software upgrade and export trend data |

|

Construction |

264 W x 359 L X 170 H mm (10.4 x 14 x 6.7 inches) |

| Control Features |

Simple user's administration |

|

Process page & Date viewer page |

|

|

Data logging/Parameters logging/Events logging |

|

|

Individual seed and amp |

|

|

Cultivation conditions setting with default values |

|

|

Automatic switch from seeding stage to cultivation stage up to 300 minutes |

|

|

Automatic air refreshing mechanism |

|

|

Tidal control |

800 ~ 1, 800 mL/min |

| Gas flow rate |

0.8 – 20 LPM (depends on system size) |

|

Alkaline addition |

80 mL/min at 100 rpm |

| Perfusion rate |

80 mL/min at 100 rpm |

|

File export |

Excel (.xlx) |

| pH control |

4~10 ± 0.1 |

|

DO control |

0%~100% ± 0.5% |

| CO2 control |

0%~10% ± 0.3% |

|

Protection |

Over pressure protection (max. 1 bar) |

|

Liquid leaking protection |

|

|

Over suction protection |

|

|

Over time protection |

|

TideXcell ® Mixing System |

|||

| Magnetic Stirrer Mixing System | Recirculation Thermostatic Mixing System | Stir-tank Mixing System | |

| Construction | Magnetic stirrer 10 L, 20 L borosilicate glass vessel with stir bar for mixing | Recirculation Mixing with magnetic driven bearing-less impeller |

Stir mixing with pre-installed impeller |

|

Electrical Requirements |

Monophase 3-threads AC 220V ± 10V 5A max 50/60 Hz | Single phase, AC 220v, 9A max, 50/60 Hz | Three phase, 230 VAC, 50/60 Hz |

| Capacity | 10 L and 20 L | 50 L, 100 L 200 L, 500 L, 1,000 L |

30 L, 50 L, 100 L, 200 L, 500 L, 1,000 L |

|

Control |

100 – 1,500 rpm stir rate RT to +45°C temperature control | Pumping rate 0 – 21 LPM RT to +50ºC temperature control |

80 – 1,000 rpm stir rate RT to +60ºC temperature control SIP system (sterilization in place) |

IV. Video

***Detailed product specifications table: TideXcell ® Pilot Scale Bioreactor & TideXcell ® - 100.No comments yet

SIGN UP FOR A CONSULTATION

Please fill in the form below and send your comments and questions to GMGA, we will respond to your email as soon as possible.

COMMIT

100% new product

COMMIT

100% refund if the product is of bad quality and not as promised

DELIVERY

Nationwide

Review Bioreactor system Esco TideXcell ®

There are no reviews yet.