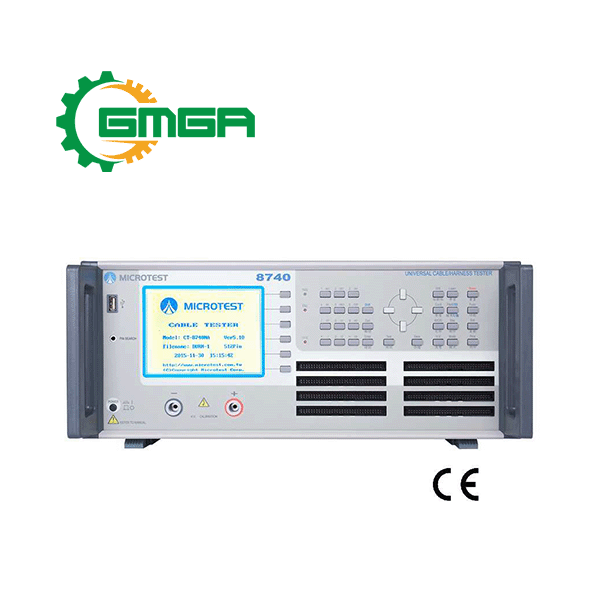

Engine Rotor testing machine MICROTEST MT-6910 (8 Channel)

Price: Contact

| Model | MT-6910 |

| Manufacturer | MICROTEST |

| Power supply | 90-132Vac or 198-264Vac |

| Weight | N/A |

| Size | N/A |

| Condition | Stocking |

| Warranty | 12 months |

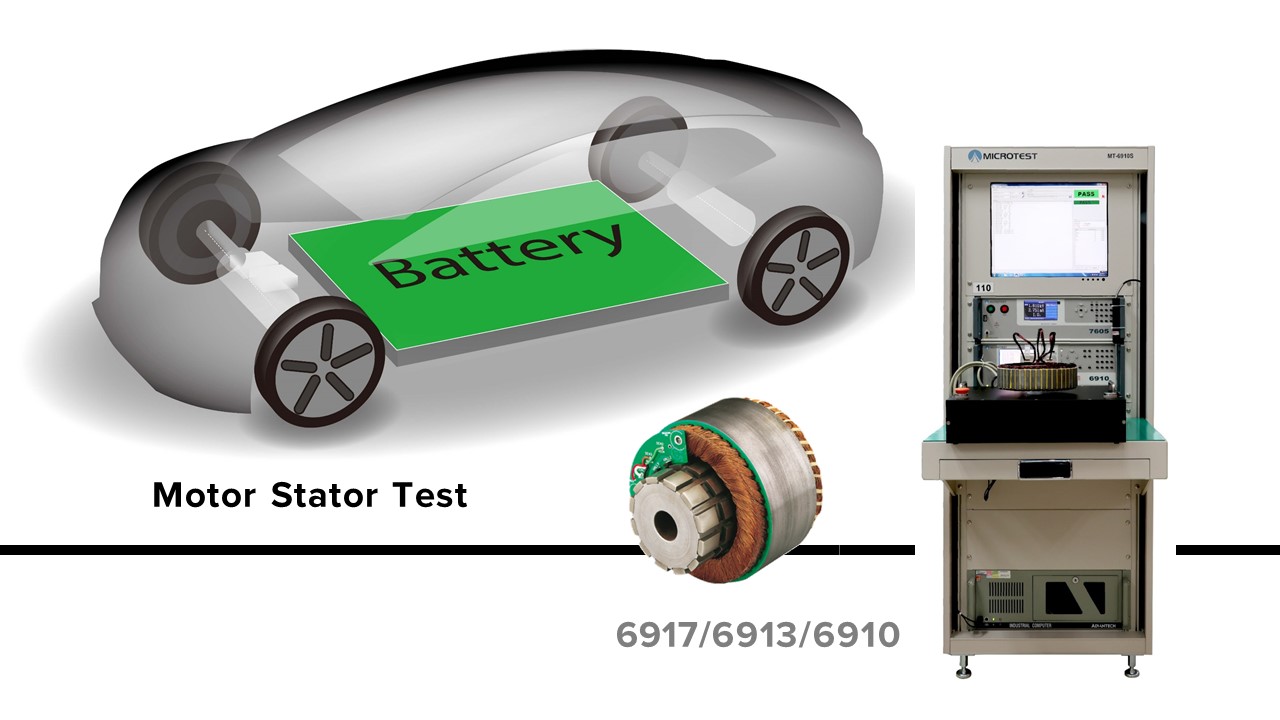

Engine Rotor testing machine MICROTEST MT-6910 is capable of setting up all measurement parameters and provides 8 test channels.

The external PC software allows for real-time data retrieval from the 6910, generating reports, or directly uploading test results to a database.

I. Specification of Motor Stator testing system MICROTEST MT-6910 (8 Channel)

Engine Rotor testing machine MICROTEST MT-6910 (8 Channel) integrates the Interlayer Short-Circuit Tester (6910), the High Voltage Withstand Tester (7605), and the LCR Tester (6365), with the 6910 serving as the main controller.

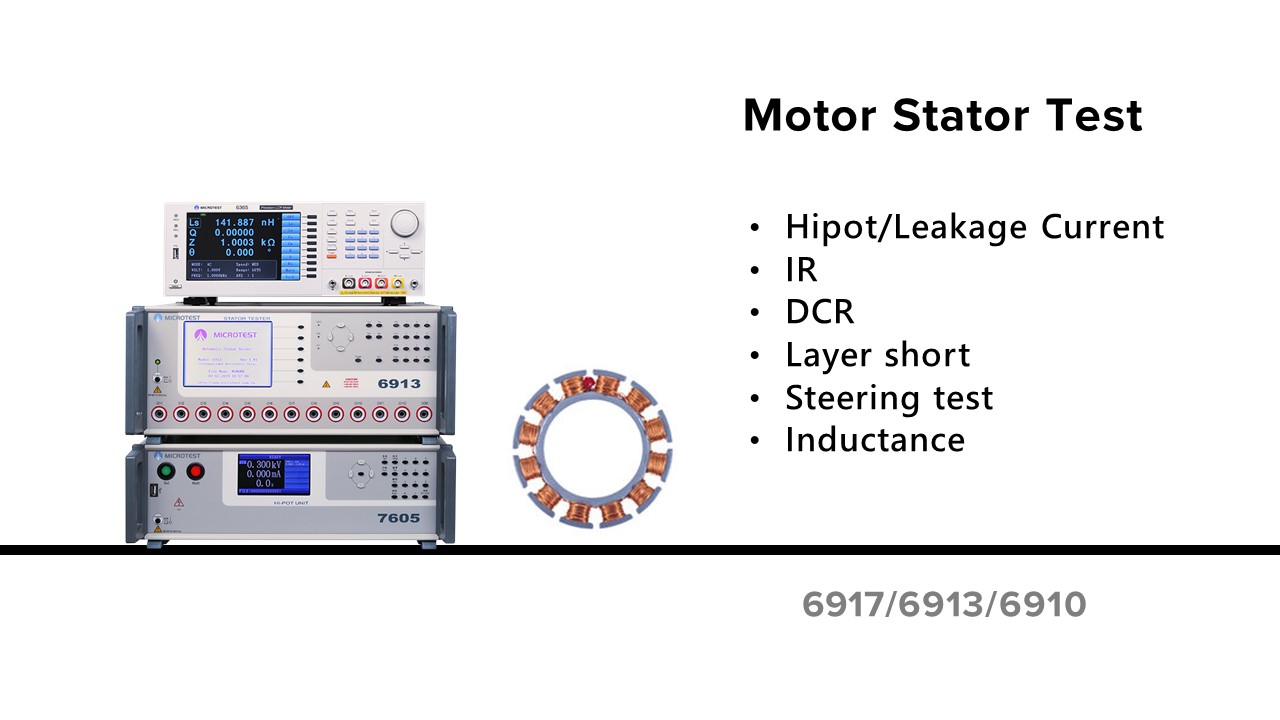

This MICROTEST MT-6910 (8 Channel) all-in-one integrated system covers safety compliance, high-voltage insulation, and coil interlayer short-circuit testing for motor stators. It can measure motor stator polarity (rotation test) using precise four-wire resistance measurement technology.

Additionally, Engine Rotor testing machine MICROTEST MT-6910 supports three-phase current balance testing (optional). The system can be equipped with PC connectivity software for data storage and can be configured with PLC control. Customized test fixtures can be provided for specific customer stators.

Furthermore, MICROTEST MT-6910 offers an optional LCR Meter for measuring the stator's inductance values with a test frequency range of 10Hz to 200kHz, supporting three-phase balanced inductance testing.

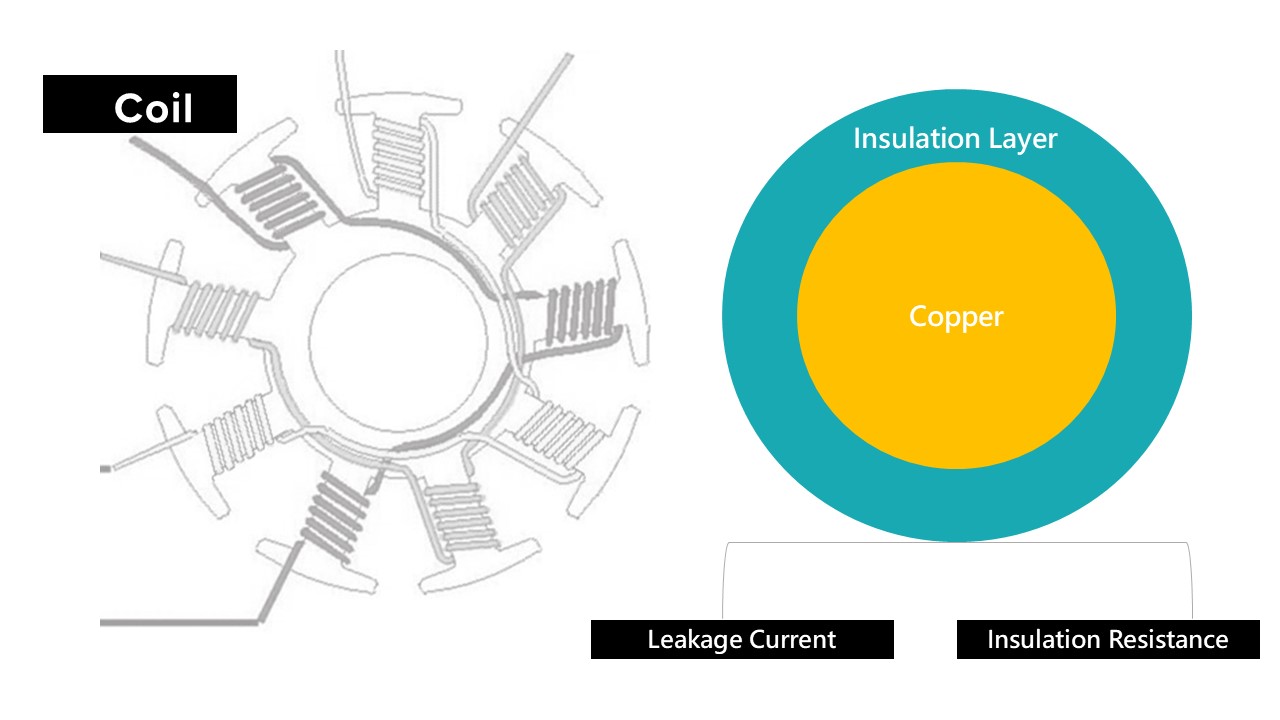

- Hipot/Leakage Current

- Insulation Resistance

- Winding Layer short Test

- Three-Phase Current Balance Test(Option)

- Steering test

- Inductance Test

- It can test multiple sets of DUTs simultaneously

- 4-Wire DC Resistance measurement will be more accurate than others

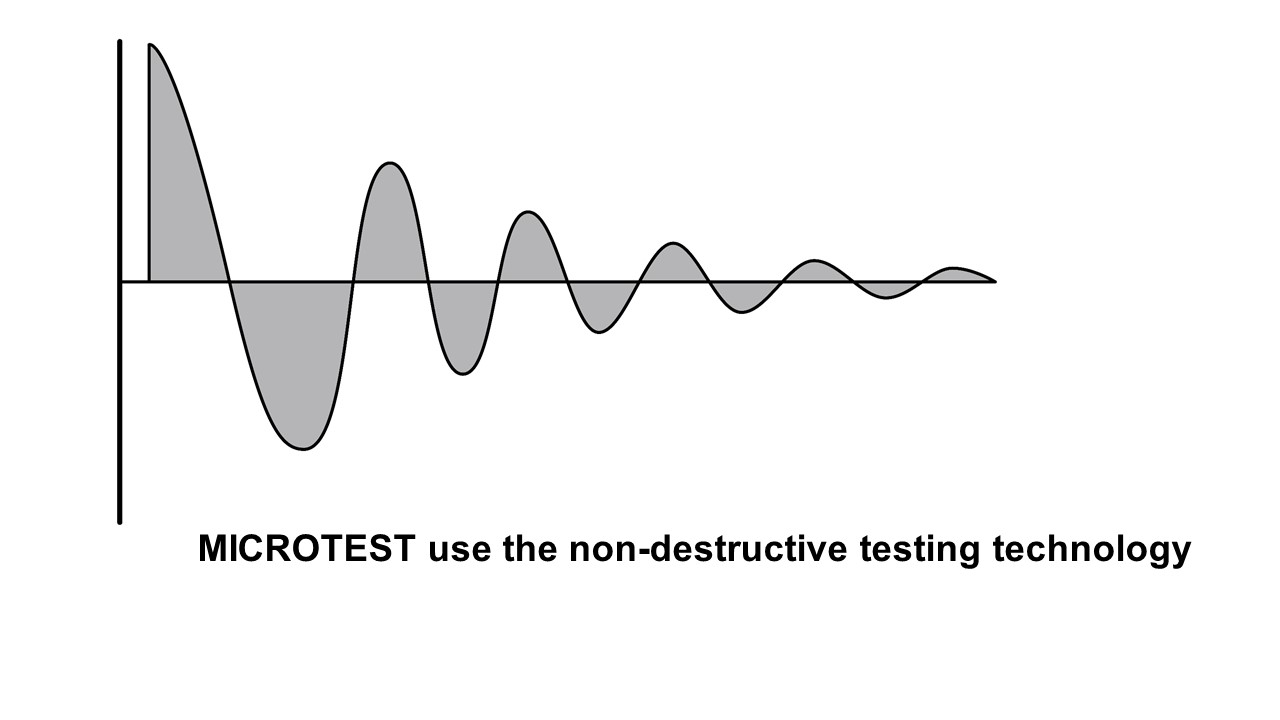

- The Impulse/Surge with waveform comparison is a non-destructive analysis

- Chinese/English screen could be switched arbitrarily.

II. Main function of Engine Rotor testing machine MICROTEST MT-6910 (8 Channel)

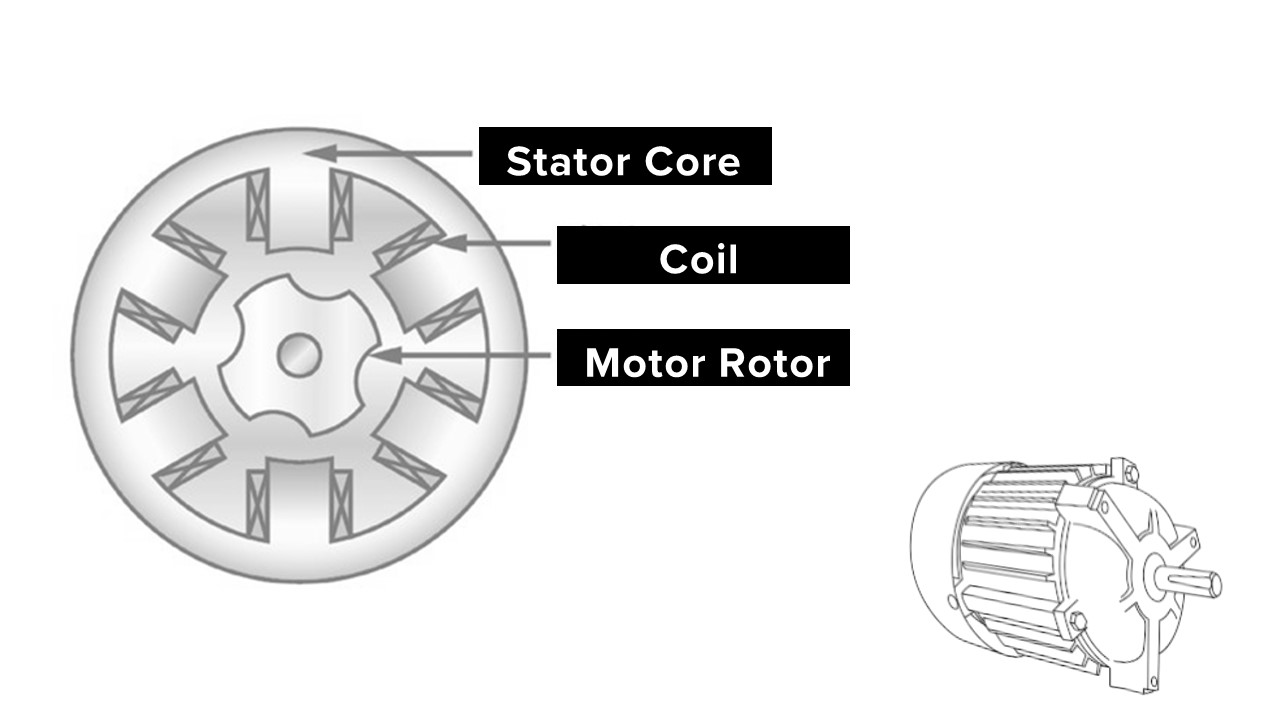

Stator Coil/Core:

- The purpose of Stator core is to be part of the magnetic route and the place to fix the Stator coil. This core is made of couple 0.5mm silicon steel sheets. To lower the magnetic loss, the core will cover by insulating paint to isolate each piece. There are couple sockets in the core to fix the Stator coil.

- Stator coil is an important component of motor. The purpose is to create inductance by current. There are single layer and double layers on the iron core.

Motor Stator test:

- Uneven DCR happen in 3-phase motor, this will cause uneven rotate.

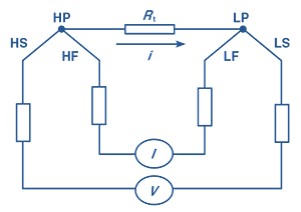

- MICROTEST MT-6910 4-Wire DC Resistance measurement will be more accurate than others.

|

|

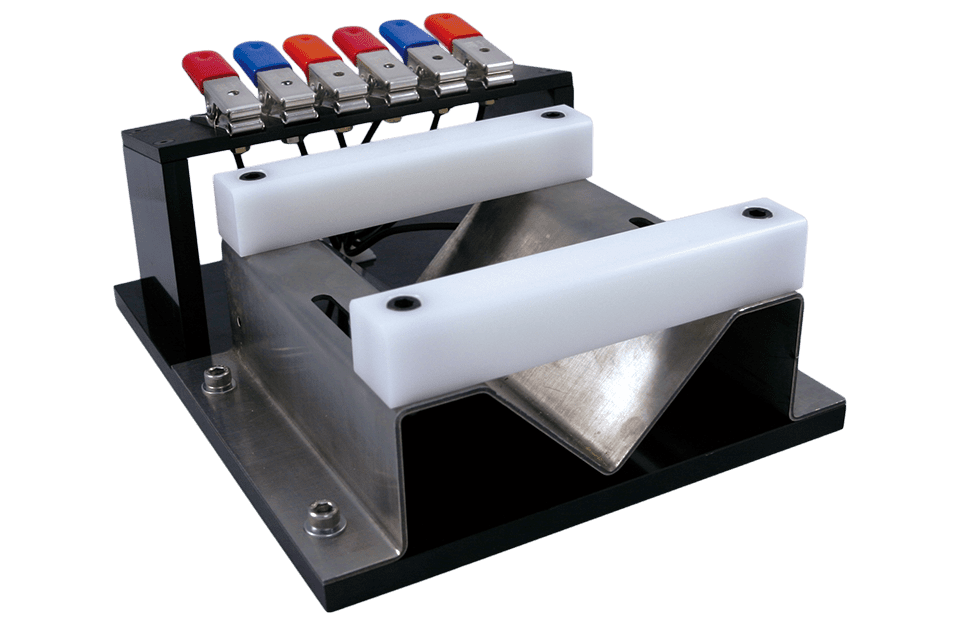

Customized test fixture for Stator coil:

For Enameled Winding of Motor:

- Conduct coil’s quality issue.

- Layer short between winding

- Short on cross winding

- Pin short

- Insulation defect.

Motor Stator testing system MICROTEST MT-6910 is One-Step-Test Function: Low Voltage Electrical Test + Hipot Test + Layer Short.

Important Parameter for Quality of Coil:

- Regular motor is winding on Silicon steel sheet

- Prevent the electricity from enameled wire to motor

- Put a insulation material on silicon steel sheet

- Insulation paint on enameled wire

- Short might happened while the current is passing the defect winging coil.

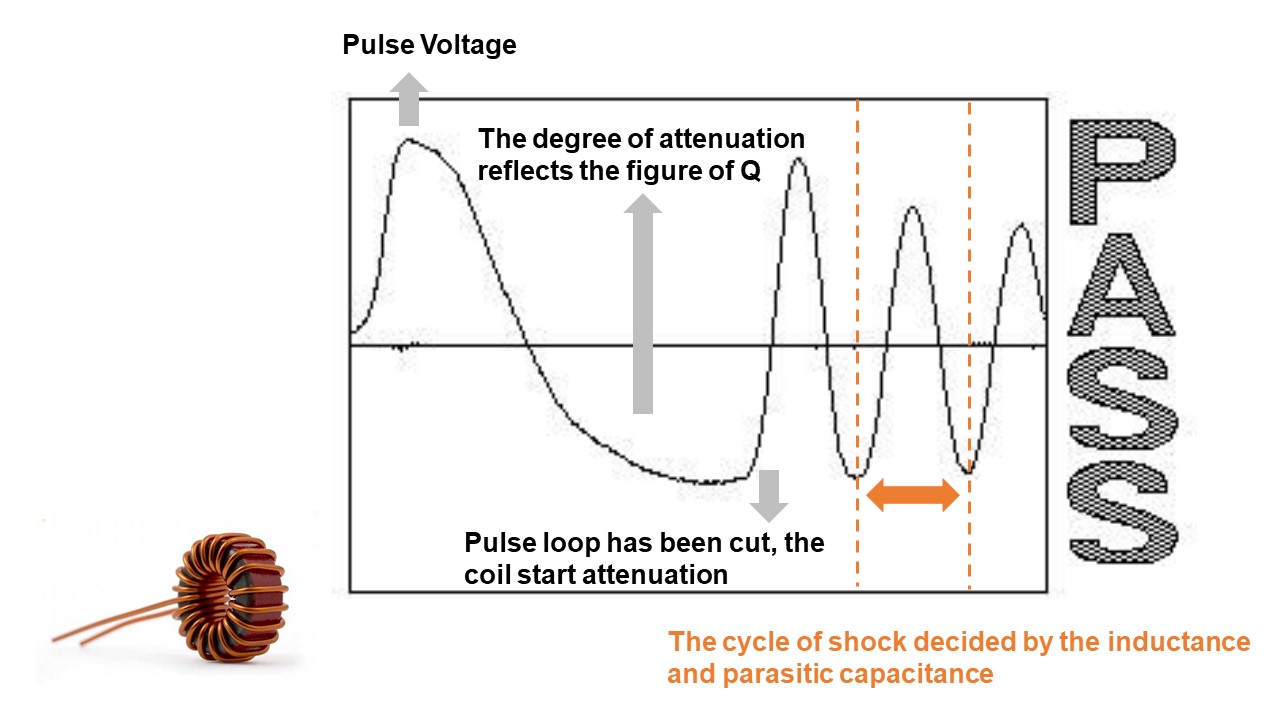

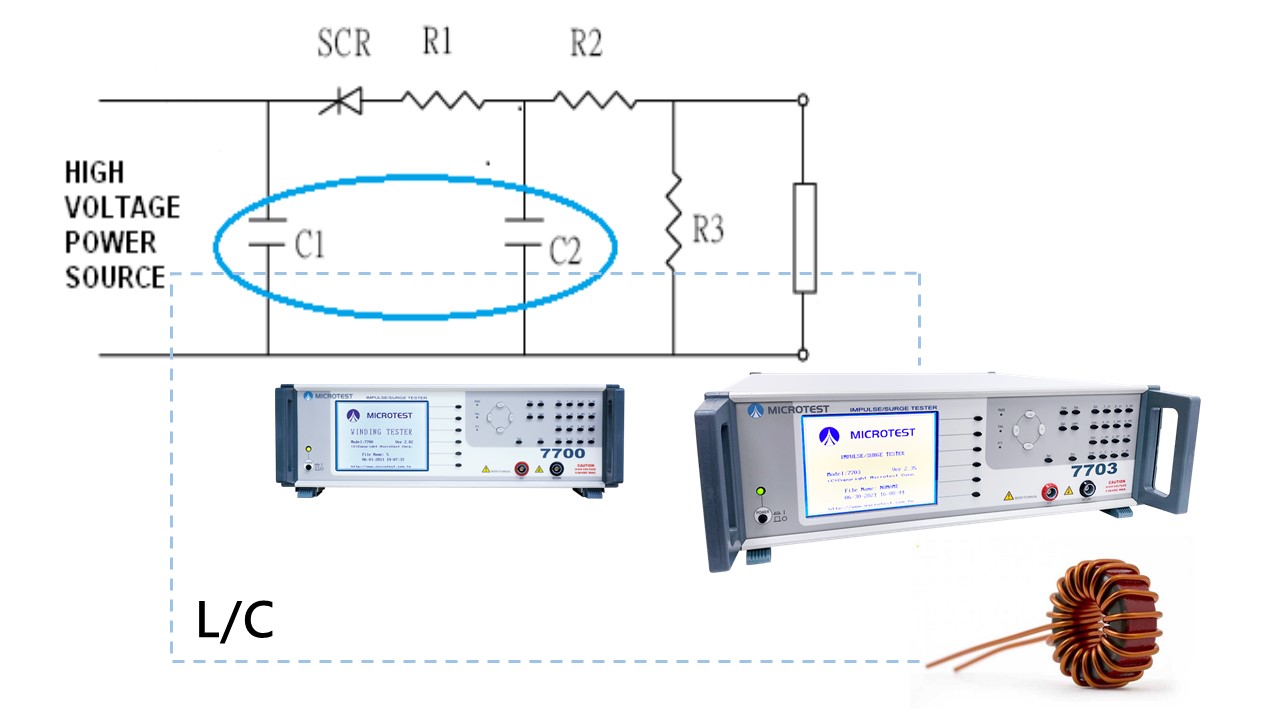

Introduction of Impulse tester:

- Impulse Winding Tester use the comparison of pulse to measure the DUT. The instrument provide high voltage to do the instant pulse test and record the wave. Compare with the golden sample to define the product.

Why do we need impulse tester for producing motor/transformer?

- Impulse Test = Quality and product life test

- The small defection is hard to find at low voltage test station. As the DUT goes to the final assembly test, the defect may show up. This will higher the cost of production.

- Motor and transformer usually work under high voltage. If we add impulse test in the product line, this may prevent the malfunction or burn on motor.

|

L |

Is the DUT coil |

|

C1, C2 |

Are the resonant capacitors in the instrument |

|

R1, R2, R3 |

Is the resistant in the instrument and the DUT |

|

Technology of Detect Layer Short |

|

|

→ 1 |

Charge the C1 capacitor to the certain testing voltage level. |

|

→ 2 |

Trigger the SCR by pulse |

|

→ 3 |

DUT will resonate with C1 and C2 |

Technology of Detect layer short:

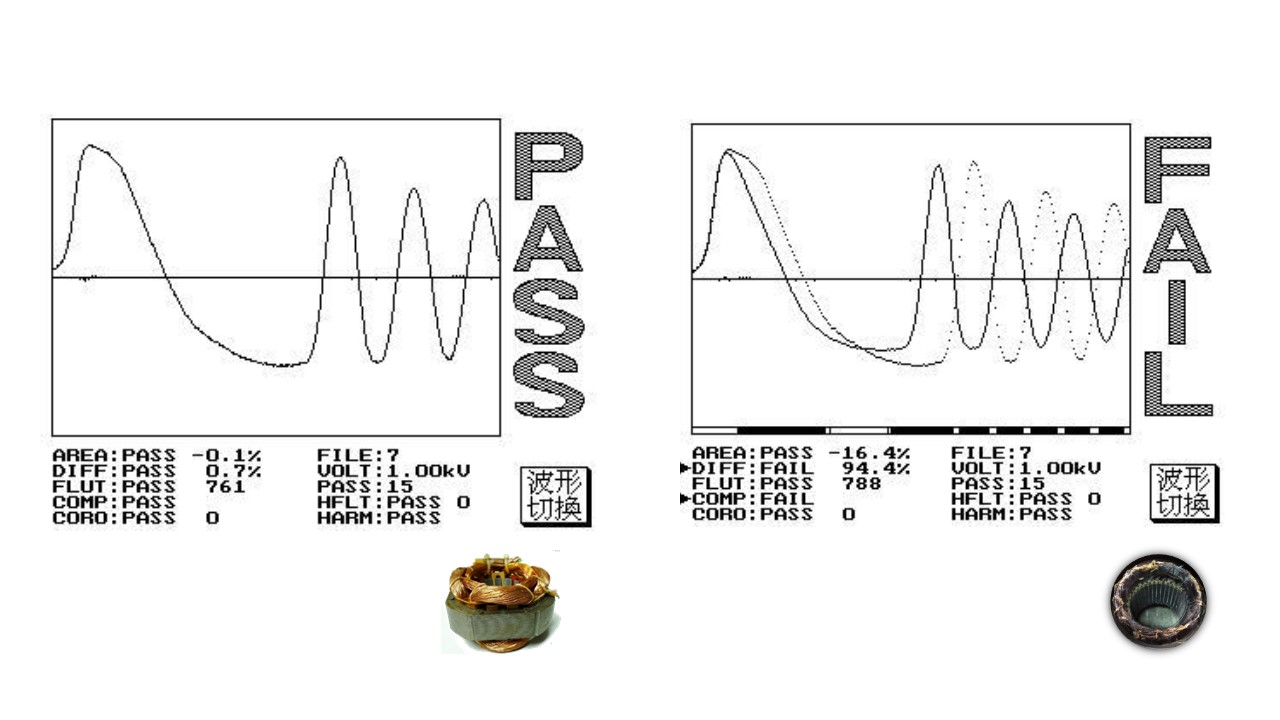

“Pulse voltage and waveform comparison” is the way we detect layer short. The pulse voltage is non-destructive/instant voltage that apply on both side of winding and detect the DUT without damage it. By compare the wave with the golden sample, we can judge the DUT.

Damping wave under L/C resonate comes from the feature change of defect coil.

- Inductance of coil

- Q rate

- Turn ratio of coil(voltage different)

- Material of core

- Layer short in the coil.

By comparing the wave of damping attenuation between golden sample and DUT:

Provides 5 waveform comparison:

- Total area comparison

- Differential area comparison

- Wave comparison

- Flat comparison

- Corona comparison.

Technical specifications of Engine Rotor testing machine MICROTEST MT-6910 (8 Channel)

MICROTEST stator testing solution can be tailored into a complete testing system based on different requirements. Firstly, you can evaluate whether to opt for a rack-mounted or desktop configuration, as well as whether to incorporate PC connectivity.

|

System |

Benchtop |

Rack |

|

|

|

|

Evaluate whether to include PC connectivity software. |

||

|

Function |

Operate directly on the instrument |

PC Link |

|

Production Traceability Management – Implementing Bar Code/Label Printer/Laser Engraver |

/ |

● |

|

Store test file sets |

100 sets (existing instruments) |

Unlimited (according to PC memory) |

|

Sharing test files between devices |

Unable to share, recreate the file |

Share through PC software |

|

Accessing test data |

/ |

Transfer test data to the PC via the RS-232 interface |

|

Uploading test data to a cloud database |

/ |

● |

|

User Permission Management” or “User Access Control |

/ |

Supports permission management, configuration through Engineering Mode |

|

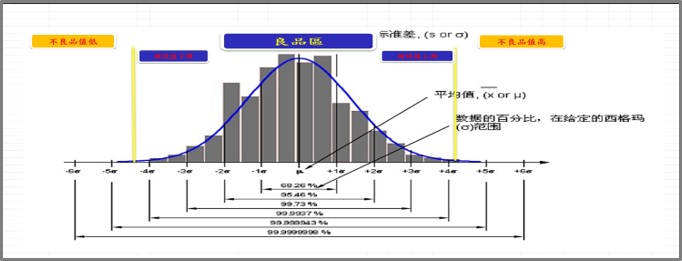

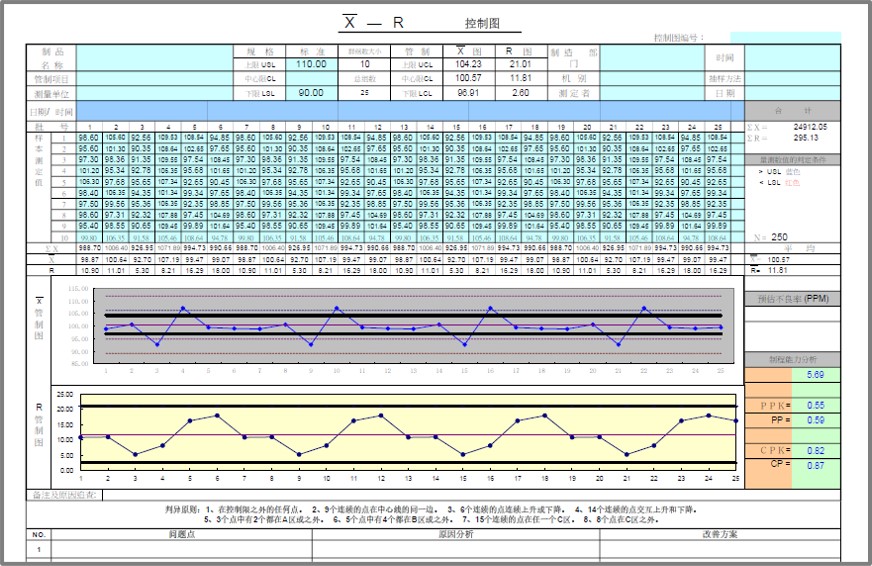

CPK Report |

/ |

|

|

Customized CPK Report According to Customer Requirements |

/ |

|

|

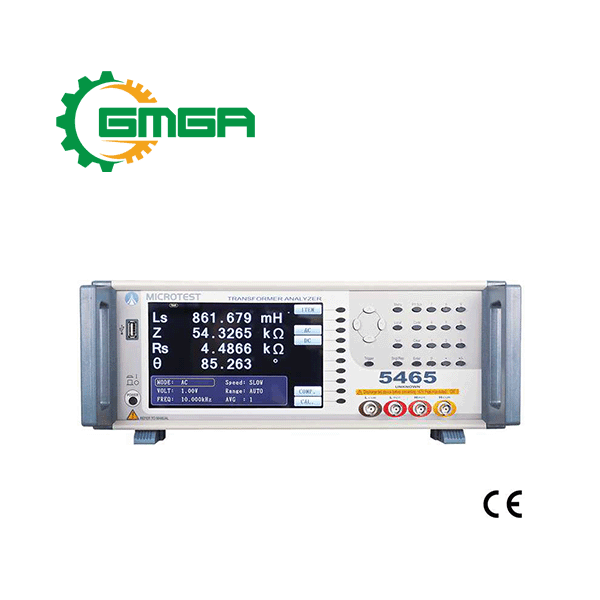

Model |

MT-6917 |

MT-6913 |

MT-6913L |

MT-6910 |

|

Test Channel |

17 |

13 |

13 |

8 |

|

DCR Range |

0.1mΩ-100kΩ |

0.1mΩ-100kΩ |

0.1mΩ-150Ω |

0.1mΩ-100kΩ |

|

DCR Accuracy |

Low Resistance |

Low Resistance |

Low Resistance |

Low Resistance |

|

High Resistance |

High Resistance |

High Resistance |

High Resistance |

|

Model |

MT-6910 |

|

DC Resistance Test |

|

|

DCR Range |

0.1mΩ-100kΩ |

|

Measuring Mode |

4-Wire |

|

Safety Hi pot Test |

|

|

AC Output Voltage |

100V-5000V |

|

AC Leakage Current |

0.001mA-10mA |

|

AC Arcing Detection |

Detect gears from 0-9 |

|

DC Output Voltage |

100V-6000V |

|

DC Leakage Current |

0.001mA-5mA |

|

DC Arcing Detection |

Detect gears from 0-9 |

|

IR Output Voltage |

100V-1000V |

|

Insulation Resistance |

1-9999MΩ |

|

Measuring Time |

0.1-99.9s Continuously adjustable |

|

Voltage Accuracy |

±(3% of setting+5V) |

|

Impulse Winding Test |

|

|

Impulse Voltage (programmable) |

200V-5000V |

|

Impulse Voltage Accuracy |

±2% |

|

Total area comparison |

When layer short happened, the loss of power on coil increase, the resonance damping coefficient increase, resonance amplitude decrease, the total area decrease. These are the basic parameters we check layer short. |

|

Differential area comparison |

Add up the difference between normal wave and DUT wave call “ Area differential”. By calculating and comparing the deference of area between golden sample and DUT. To determine the degree of waveform overlap. |

|

Wave comparison |

Set a acceptable wave range, if the DUT’s wave is in this range shows “pass” otherwise, “fail” |

|

Corona comparison |

In pulse test, the insulation defect will cause discharge and create corona. This function is able to count the times that corona happened base on the degree of deviation. |

|

Flat comparison |

If the layer short happened, the waveform will tremble. Therefore, the instrument will quantize and compared it. |

|

Inductance Measurement (Option LCR Meter 6365) |

|

|

Inductance Ranges |

0.1nH – 99.999KH |

|

Test Frequency |

10Hz-200kHz |

|

Frequency Output Accuracy |

±0.01% |

|

Frequency Resolution |

5 Digits |

|

AC Drive Level |

10mV to 2Vrms (1m Vrms resolution) |

|

Basic Accuracy |

±0.1% |

|

Three-phase Inductance Balance Test |

Comparison Mode – The absolute value of the difference between the two sets of coil inductance |

System:

|

Test fixture |

According to the test requirements |

|

|

Indicator |

Pass/Fail Screen Diaplay/Sound |

|

|

Built-in Storage |

Storage of 100 rewritable data sets |

|

|

Operation |

Manual, RS-232 |

|

|

Power Supply |

Voltage |

90-132Vac or 198-264Vac |

|

Frequency |

50/60Hz |

|

|

Power consumption |

300VA |

|

|

Environment |

Temperature |

10℃-40℃ |

|

Humidity |

20-90%RH |

|

|

Display |

6910 |

5.7″ dot-matrix display (320*240) |

|

7605 |

4.3″ TFT LCD (480*272) |

|

|

6365 |

7.0″ TFT (800*480) |

|

|

Dimension (W*H*D) |

6910 |

435x190x522mm |

|

7605 |

435x145x522mm |

|

|

6365 |

435x145x522mm |

|

|

Weight |

6913/6913L |

15 Kg |

|

7605 |

14 Kg |

|

|

6365 |

3 Kg |

|

|

Interface |

RS-232 |

|

No comments yet

SIGN UP FOR A CONSULTATION

Please fill in the form below and send your comments and questions to GMGA, we will respond to your email as soon as possible.

COMMIT

100% new product

COMMIT

100% refund if the product is of bad quality and not as promised

DELIVERY

Nationwide

Review Engine Rotor testing machine MICROTEST MT-6910 (8 Channel)

There are no reviews yet.