Laser large roller alignment machine RollCheck® Max SX-6150

Price: Contact

| Model | SX-6150 |

| Manufacturer | Seiffert Industrial |

| Power supply | Polymer li-Ion battery. 3.7v 4000mAh |

| Weight | 12.8 kg |

| Size | 736 x 457 x 275mm |

| Condition | Stocking |

| Warranty | 12 months |

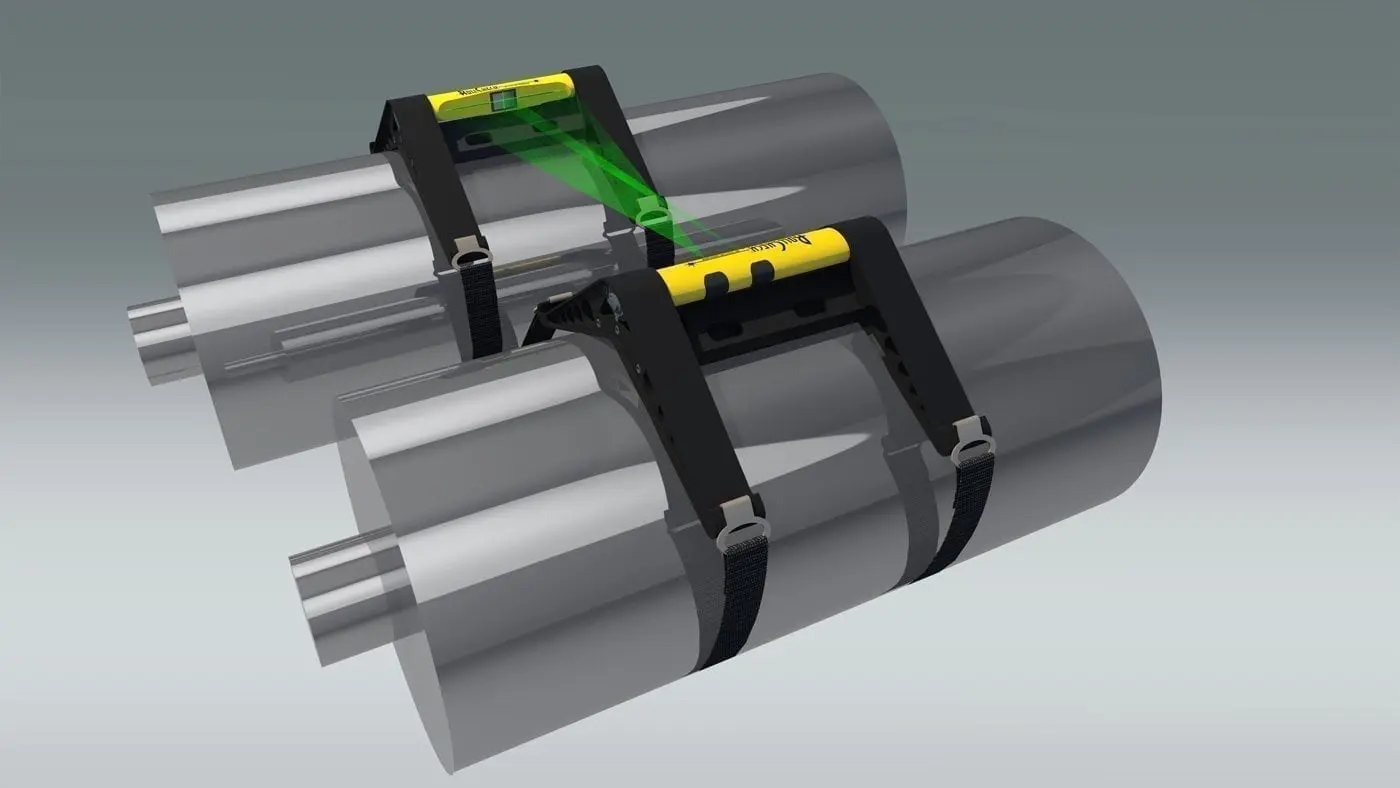

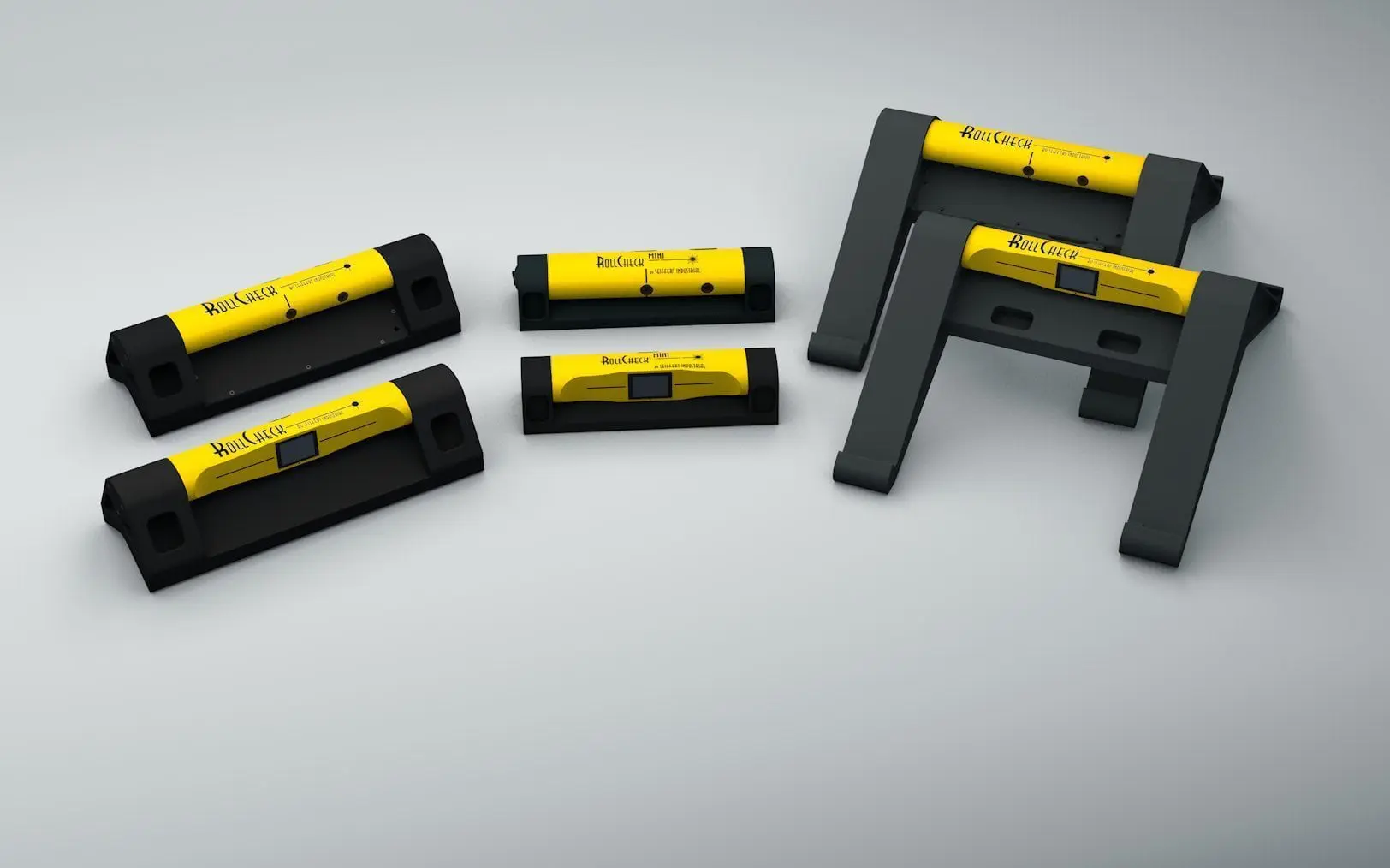

The Laser large roller alignment machine RollCheck® Max SX-6150 from manufacturer Seiffert Industrial is lightweight, compact and durable. This Laser roller alignment systems can be attached to just about any size roll with the supplied straps.

I. Specification of Laser large roller alignment machine RollCheck® Max SX-6150

- Laser roller alignment machine RollCheck® Max SX-6150 use proven reflected laser beam technology for maximum angular resolution, thus providing you with the most reliable and accurate visual reading. Using the latest in Green laser diode technology makes green laser line 10x’s brighter to the operator than a red laser line.

- This Laser roller and roll alignment system RollCheck® Max SX-6150 can measure spans up to 10 ft. (3 m) or better from roll to roll of any size, large or small. A laser line is projected from the RollCheck® transmitter Model SX-6150T to the reflector Model SX-6150R mounted on the roll to be checked or aligned. The laser line projected to the reference line on the reflector indicates immediately if the roll is aligned vertically to the stationary roll. The laser line is then automatically reflected back to the transmitter’s reference line indicating if the rolls are parallel to one another.

- This Laser roll alignment systems is very easy to use; a single person can perform the alignment task in minutes with no training!

II. Features of RollCheck® Max SX-6150

- Designed for medium to large machines

- 4 inch or 101mm to 8 foot or 2400mm roll diameters

- Shots greater than 10 feet or 3 meters

- Bright GREEN laser lines

- Rechargeable lithium ion batteries

- Reduces down time and product waste due to misalignment of rolls

- Increases production with proper alignment of rolls

- Compact design, fits into small spaces

- FAST and EASY to use

- No training required

- One-person operation

- Facilitates more frequent roll checks

- Pays for itself quickly

- Uses proven reflected laser beam technology.

III. Application of Laser roll and roller alignment tools RollCheck® Max SX-6150

- Utilizing the Laser large roller alignment machine RollCheck® Max SX-6150 to measure and correct vertical and horizontal angle between 2 rolls.

- RollCheck® Max SX-6150 is a laser roll alignment system that facilitates accurate visual alignment of process rolls during replacement operations. The Laser Transmitter Model SX-6150T is mounted to a stationary roll that transmits two green laser lines to the Reflector Model SX-6150R positioned on the roll to be moved. The operator then is able to view both the vertical (pitch) and horizontal (parallel) angles and accurately adjust the roll into parallel alignment.

- RollCheck® Max SX-6150 is suitable for aligning rolls of most diameters that are spaced from 6” (152 mm) to 10 ft. (3 m) or more apart. It also can be used to align and measure crowned rolls as well.

- RollCheck® Max SX-6150 help eliminates cumbersome trial and error adjustments which lead to scrap, loss of time and output reduction and is the ideal tool for efficient roll maintenance.

Technical data of Laser large roller alignment machine RollCheck® Max SX-6150

|

Transmitter Model SX-6150T |

|

|

Operating distance |

Max. 10 ft. (3 m) |

|

Accuracy |

< 0.001”/ft. (< 0.03 mm/m) |

|

Laser type |

2 ea. 532nm visible green laser lines, 45 ̊ full angle |

|

Laser power |

< 1mW, Class 2 |

|

Safety precautions |

Do not stare into beam |

|

Laser compliance |

CFR parts 1040.10 and 1040.11 |

|

Laser line thickness |

0.017” (0.4318 mm) at 9 ft. (2.8 m) |

|

Laser calibration |

Factory calibrated, check yearly |

|

Environmental protection |

Water resistant, dust proof and impact resistant |

|

Controls |

Laser ON/OFF rocker switch |

|

Battery type |

High power polymer li-Ion rechargeable battery. 3.7v 4000mAh |

|

Operating time |

16 – 20 hours continuous at 72 ̊ F (22 ̊ C) |

|

Temperature |

Operating:32 ̊ F (0 ̊ C) to 125 ̊ F (52 ̊ C) |

|

Frame |

Rigid aluminum frame, powder-coat paint finish |

|

Laser housing |

Aluminum, powder-coat paint finish |

|

Mounting diameters |

Roll diameters 4” (101mm) up to 8’ (2400mm) |

|

Mounting straps |

Set of 2 attachment straps included: |

|

Weight |

8.8 lbs. (4.0 Kg) |

|

Dimensions |

12” (305mm) W x 16.5” (419mm) D x 6” (152mm) H |

|

Reflector Model SX-6150R |

|

|

Reflector size |

1” (25 mm) x 1.4” (36 mm) |

|

Frame |

Rigid aluminum frame, powder-coat paint finish |

|

Reflector housing |

Aluminum, powder-coat paint finish |

|

Mounting straps |

Set of 2 attachment straps included: 2 ea. 10” (254 mm) to 45” (1143 mm) adjustable bungee straps for diameters up to 15” (381 mm) |

|

Weight |

9.0 lbs. (4.1 Kg) |

|

Dimensions |

12” (305mm) W x 16.5” (419mm) D x 6” (152mm) H |

|

Carrying Case |

|

|

Material |

Black, high density hard polyethylene |

|

Dimensions |

29” (736mm) W x 18” (457mm) D x 10.85” (275mm) H |

|

Insert |

Die cut foam |

|

Carrying case weight |

28.2 lbs. (12.8Kg) |

|

Total system weight |

46.4 lbs. (21.0Kg) |

No comments yet

SIGN UP FOR A CONSULTATION

Please fill in the form below and send your comments and questions to GMGA, we will respond to your email as soon as possible.

COMMIT

100% new product

COMMIT

100% refund if the product is of bad quality and not as promised

DELIVERY

Nationwide

Review Laser large roller alignment machine RollCheck® Max SX-6150

There are no reviews yet.