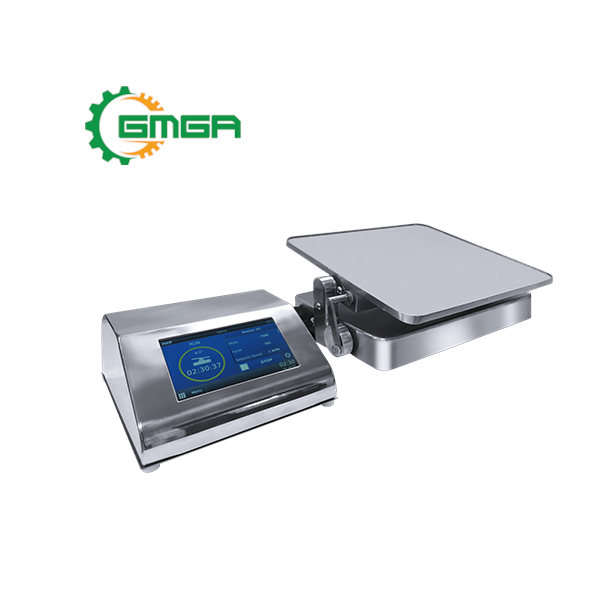

Benchtop bioreactor Esco CelCradle™

Price:

| Model | |

| Manufacturer | |

| Power supply | |

| Weight | |

| Size | |

| Condition | |

| Warranty |

I. Specification Esco VXL™ (HBR) cell culture machine

- The ready-to-use bottles, which are part of single-use manufacturing, eliminate validation costs compared to a multiple-use system when starting your next cell culture. Esco CelCradle™ bioreactor components are pre-sterilized, prepackaged to speed up your research whether for vaccine, stem cell or virus production applications.

Tides in motion in the CelCradle™ culturer:

- The Esco CelCradle™ "Tide Movement" Principle contains the encapsulated buffer (BioNOC™ II) and the media container in the same bottle. When the bellows is pushed up, the cells attached to the carrier are submerged into the culture medium, in contrast to the cells taking up nutrients. When the bellows is released, the cells are exposed to air in an aerated medium.

Advantages of the Esco CelCradle™ bioreactor:

- SS 316 L Carcass for easy cleaning

- Compact and easy-to-install tabletop design, with small legs

- Pre-sterilized bottles, disposable, disposable

- Conductive medium: Cells are grown in an ultra-low shear stress, foam-free, and O2-limited medium.

- Esco CelCradle™ is compatible with most serum-free media

- Surface of Macroporous service providers. To grow most cells dependent on the anchor and to allow easy harvesting of whole cells, cell components or secreted proteins

- Provides large surface area up to 15,000 cm2 per bottle for adhesion cell growth

- The ability to produce hundreds of milligrams to several grams of secretory protein or monoclonal antibodies per month in four bottles

- Few parameters for easy optimization

- Culture in batch, batch, or cyclic modes

- Scaling through the TideXcell pilot scale bioreactor or through direct multiplication of the number of bottles used.

Applications of the Esco CelCradle™ shaker:

- Mammal and insect cell culture

- Producing monoclonal antibodies

- Gene and Cell Therapy (autologous)

- Produce Viral . Vectors

- Pharmacokinetic studies

- Vaccine production

- Research and make medicine

- Producing proteins

- Proteome Research.

II. Model of the Esco CelCradle™ bioreactor system

Complete CelCradle system:

- Simple to operate and virtually moves on the same CelCradle unit stage but uses CelCradle™ 500 and 500A bottles.

CelCradle continuity system complete:

- Same CelCradle unit stage but using CelCradle™ 500P and 500AP for continuous process.

III. Benchtop bioreactor Esco CelCradle™ - Cyclic process mode

- The Esco CelCradle™ single-use bioreactor is equipped with a CelFeeder™ for automatic recirculation during culture. The CelFeeder system is designed to simplify the replacement of culture media through continuous harvesting and feeding. Daily feeding volume and feeding frequency can be controlled in this process.

- Using the Esco CelCradle™ 500AP bottle, tubes from the media container will be connected to its feeding and harvesting port. The medium bottle shall contain fresh culture medium in a volume of 1 L or 2 L and its cap shall be replaced with a connector. This connector has replaceable hoses and pump head for recirculation setting.

Three easy steps to monitoring:

- CelFeeder Setup: Parameters like cycle/day and volume can be set using this unit.

- Prepare bottles with connection system: Change bottle caps using the adapter provided in the complete CelCradle continuity system.

- Connection to CelCradle Bottle: The CelCradle™ 500AP bottle is equipped with a feed and harvest port for connection to medium tanks.

***You may be interested in GMGA's ART workstation - Esco Vietnam: https://gmga.vn/en/danh-muc/process-equipment/workstation-art/

***You may be interested in GMGA's ART workstation - Esco Vietnam: https://gmga.vn/en/danh-muc/process-equipment/workstation-art/

IV. Specifications benchtop bioreactor Esco CelCradle™

CelCradle™ Stage Technical Specifications |

|

|

Dimension |

264 W x 359 L X 170 H mm (10.4 x 14 x 6.7 inches) |

| Weight |

7.0 kg(15.4 lb) |

|

Power |

100~230 VOLTS AC, 50/60 Hz (Input); 12 VOLTS DC (Output_) |

| Up-Down Rate |

0.25 to 2.0 mm/sec. |

|

Step of 1.0 sec or 1.0 min. |

|

| Delay Time |

0 to 99 min 59 sec |

|

Step of 1.0 sec or 1.0 min. |

|

| Driver Motor |

DC stepping-motor |

|

Environment |

20 ~ 42 °C, 0 ~ 90% relative humidity (in a CO2 incubator) |

| Mechanical Protection |

Hi-low Optical Sensor |

|

Transmission |

Gear set (ration 1:1.2) and belt |

| Recommended CO2 incubator dimension |

CelCradle Complete: CCL-170L model: 505 x 535 x 633 mm(19.9" x 21.1" x 24.9") and CelCradle Continuous SYstem Complete: CCL-240L model: 595 x 640 x 633 mm (23.4" x 25.2" x 24.9") |

CelCradle™ Controller Technical Specifications |

|

|

Dimension |

137 L x 226 W x 40 D mm (5.4 x 8.9 x 1.6 inches) |

| Weight |

1.16 kg(2.6 lb) |

|

Power |

100-230 VOLTS AC 50/60 Hz (input): 12 VOLTS DC (Output_) |

| Environment |

Room temperature (outside CO2 incubator) |

|

Materials |

Magnetic back plate, to hold the controller to the side of the incubator |

CelFeeder™ Controller Technical Specifications |

|

|

Dimension |

230 W x 131 D x 61 H mm, (5.2 x 9.1 x 2.4 inches) |

| Weight |

0.645 kg (1.42 lb) |

|

Power |

85~240 Volts AC, 50/60 Hz (input); ~180 mA |

| Environment |

Ambient to 45°C, ~95% Relative Humidity |

V. Video

***Detailed product specification sheet: CelCradle™ Benchtop Bioreactor.No comments yet

SIGN UP FOR A CONSULTATION

Please fill in the form below and send your comments and questions to GMGA, we will respond to your email as soon as possible.

COMMIT

100% new product

COMMIT

100% refund if the product is of bad quality and not as promised

DELIVERY

Nationwide

Review Benchtop bioreactor Esco CelCradle™

There are no reviews yet.