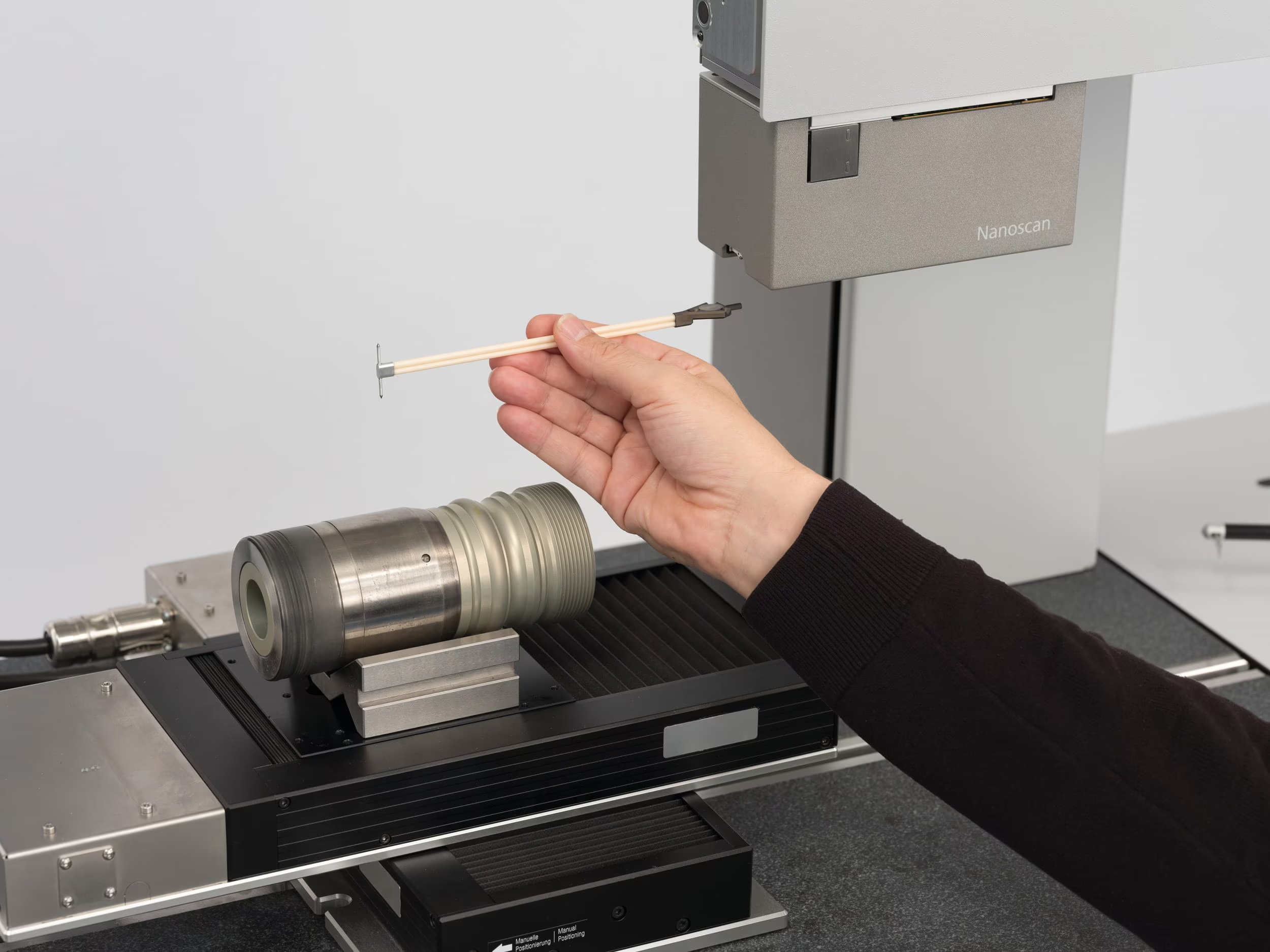

Stationary roughness and contour measurement meter HOMMEL ETAMIC Waveline W600 & Waveline W800 & Waveline W900

Price: Contact

| Model | Waveline W600 / Waveline W800 / Waveline W900 |

| Manufacturer | Brand HOMMEL ETAMIC (a part of the JENOPTIK AG) |

| Power supply | 100-240 V AC 50/60 Hz |

| Weight | N/A |

| Size | N/A |

| Condition | Stocking |

| Warranty | 12 months |

Stationary roughness and contour measurement meter HOMMEL ETAMIC Waveline W600 & Waveline W800 & Waveline W900 with all measuring station configurations are modular in design and can therefore be easily expanded at a later date.

With these HOMMEL ETAMIC Waveline systems, you measure surfaces exactly as it fits your individual infrastructure and your specific measurement tasks.

I. Stationary roughness and contour measurement meter HOMMEL ETAMIC Waveline W600 & Waveline W800 & Waveline W900 for your applications

Stationary roughness and contour measurement meter HOMMEL ETAMIC Waveline W600 & Waveline W800 & Waveline W900 with maximum flexibility and efficiency in daily measuring practice.

At the same time, the measuring systems are easy to operate and have a wide range of analysis options thanks to the Evovis measuring and evaluation software.

- Universal, easy-to-use measuring system

- High measurement quality thanks to stable mechanics

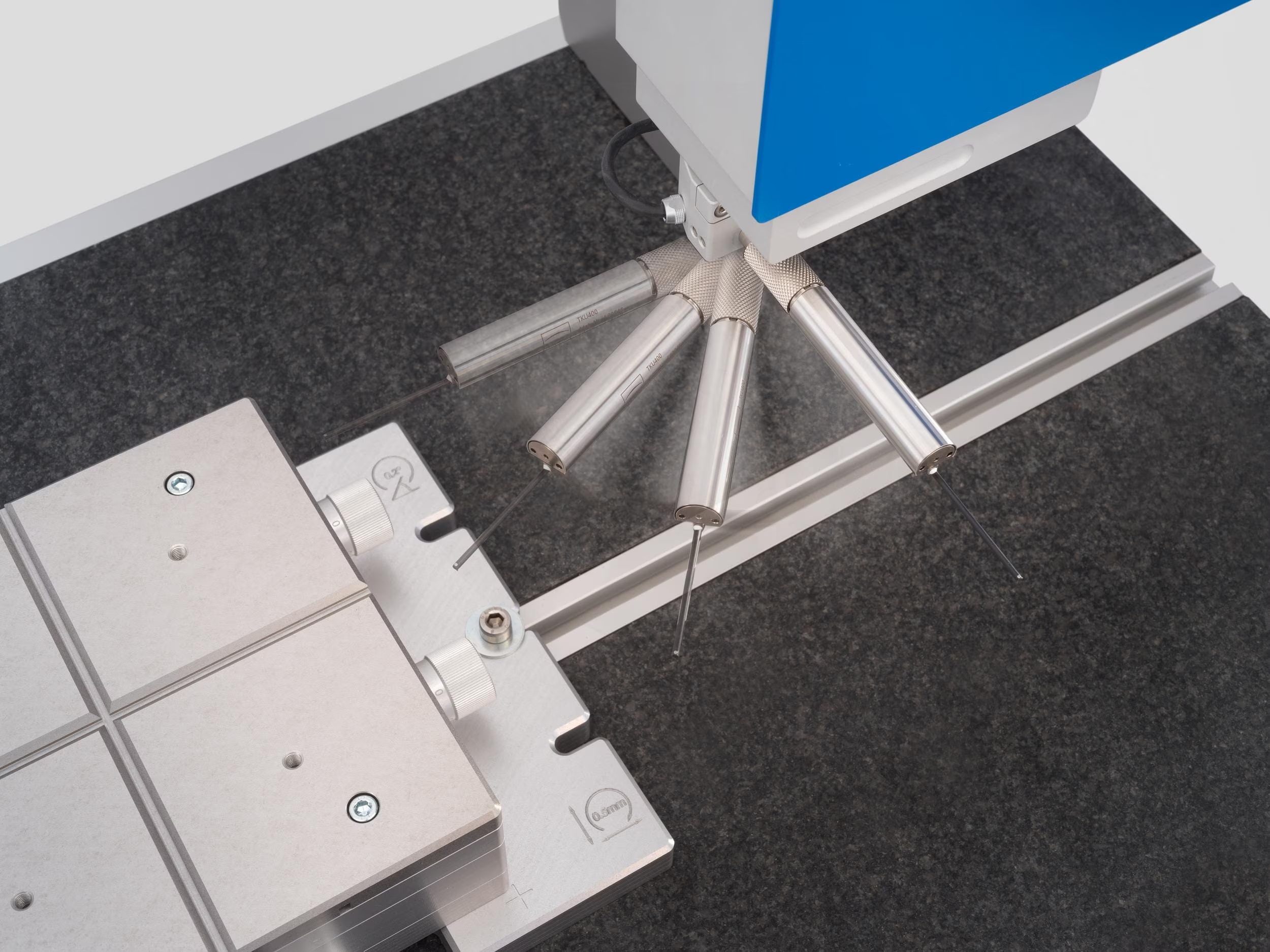

- Quick-change adapter QCA enables quick probe system changeover with minimum retooling time and automatic configuration feature.

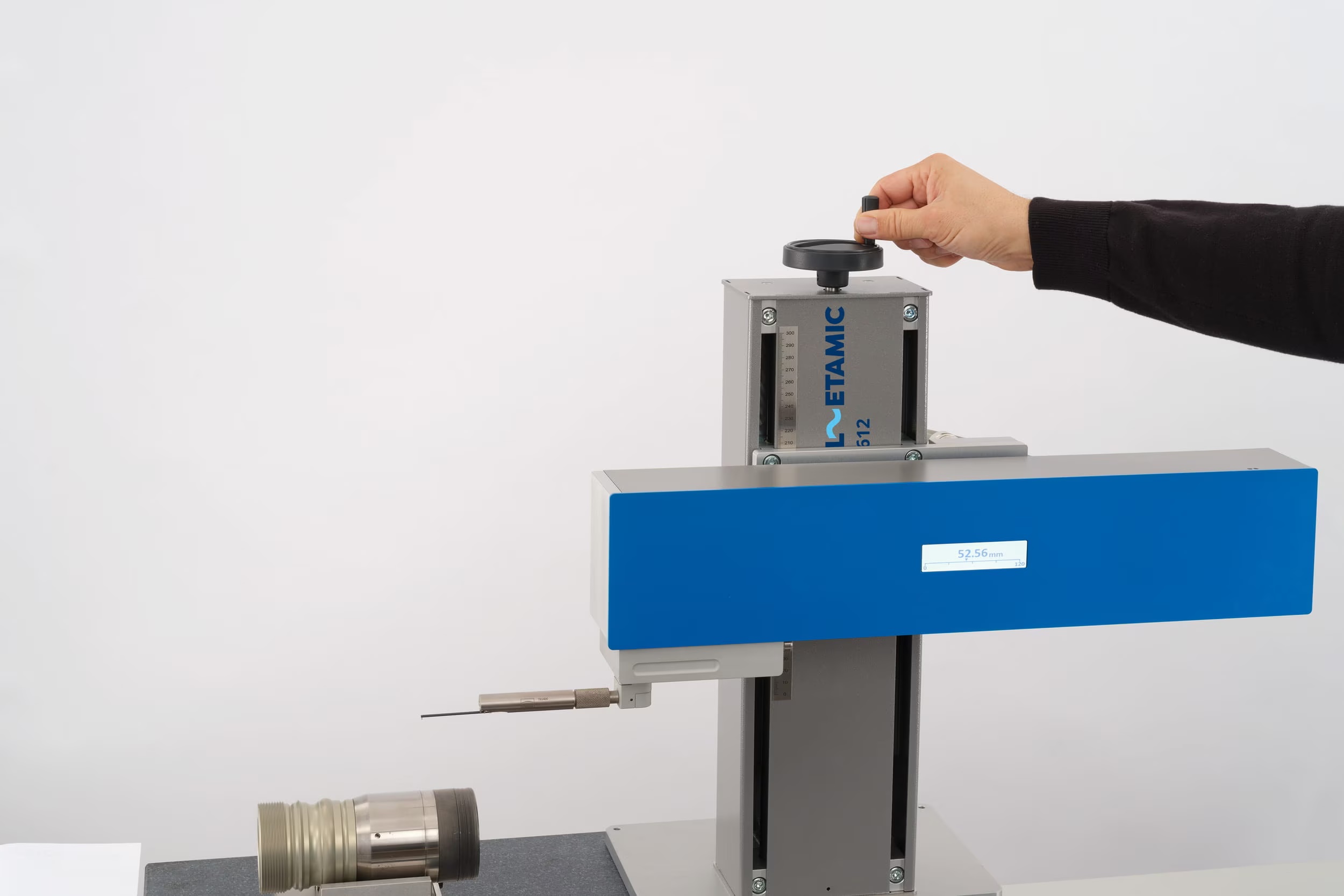

A. Waveline W600: Compact measuring systems with simple operation

- Universal, easy-to-use measuring system

- High measurement quality thanks to stable mechanics

- Unique traverse concept for optimum accessibility of the measuring points

- Modern touch probes with high resolution

- Interface for probe systems for either roughness or contour measurement with TKU400 or Digiscan probe system

- Quick-change adapter QCA enables quick probe system changeover with minimum retooling time due to automatic probe recognition

- Sophisticated probe arm technology

- Probe arms with magnetic coupling for fast and easy probe arm changeover

- All contour probe arms with RFID chip for simplified calibration and automatic configuration

- Measuring points freely accessible thanks to unique traverse unit concept

- Manual height adjustment with handwheel for precise probe positioning

- Optional base plate for mounting on granite plate with T-slot or threaded bushings provides numerous mounting options

- Measurement and evaluation software Evovis with modern interface and extensive functions

- Subsequent expansion of the measuring system possible due to modular design.

|

Model |

W600R |

W600C Digiscan |

W600RC Digiscan |

|

Traverse unit [mm] |

120 |

120 |

120 |

|

Measuring column [mm] |

300 |

300 |

300 |

|

Granite plate [mm] |

700x400x100 |

700x400x100 |

700x400x100 |

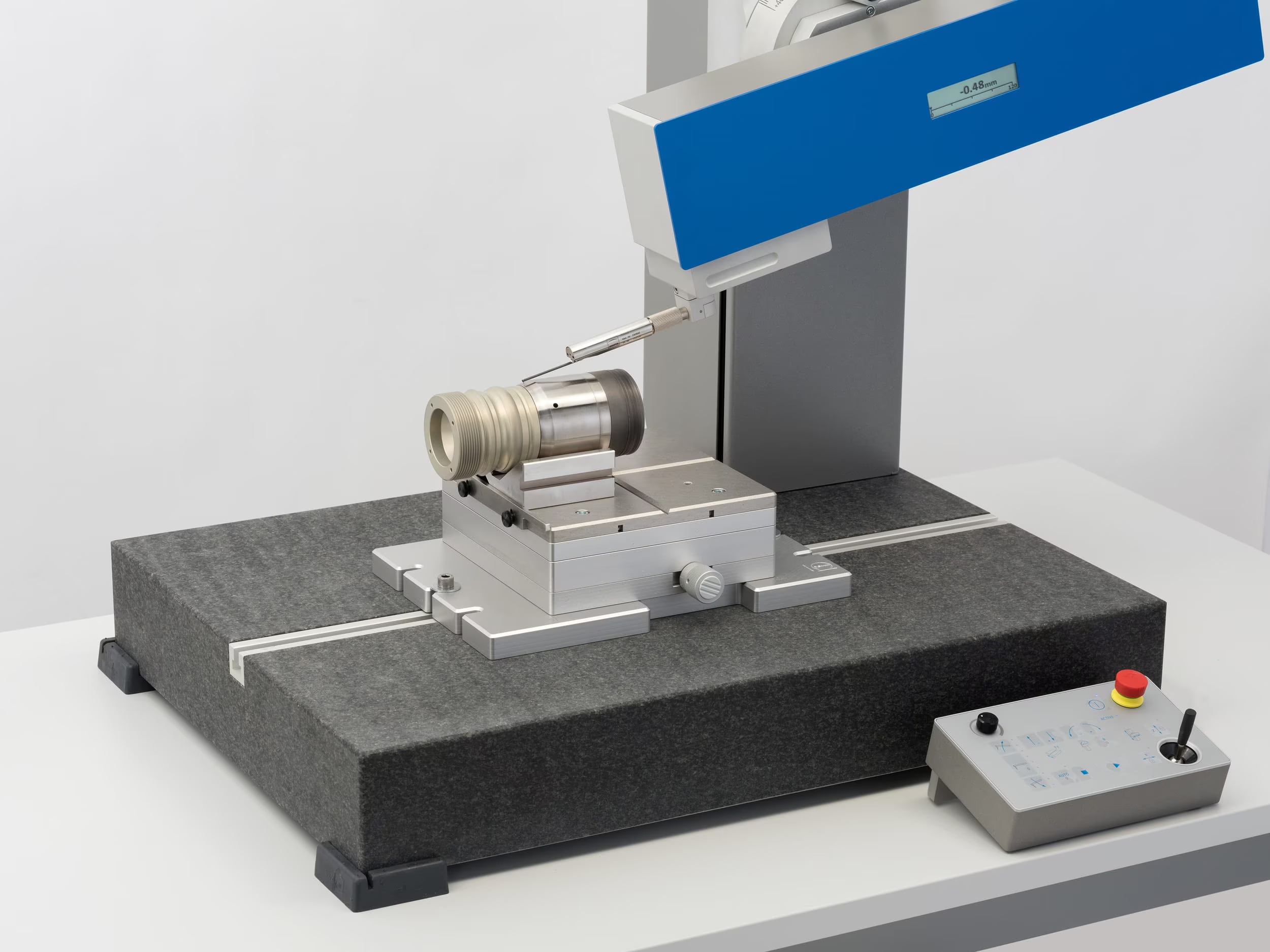

B. Waveline W800: Modular system concept for maximum flexibility

Stationary roughness and contour measurement meter HOMMEL ETAMIC Waveline W800 have been developed for roughness and contour measuring tasks associated with typically manual or semi-automatic measuring processes. The systems are easy to operate and offer a great variety of analyses thanks to the performant measuring and evaluation software Evovis. The result is the highest standard of measuring accuracy in the shortest time.

The quick-change adapter enables probe systems to be changed over without having to use any tools. Probe arms and probe system are equipped with magnetic coupling making the exchange of probe arms easy and fast. This means you can take a flexible approach towards all of your measuring requirements.

The system automatically detects the intelligent contour probe arms with RFID identification and adjusts the optimal measurement conditions, thus practically eliminating operating errors and incorrect measurements.

- Universal, easy-to-use measuring system

- Modern, high-resolution probe systems

- High measurement quality thanks to stable mechanics

- Sophisticated probe arm technology

- Unique traverse unit concept for optimum access to measuring positions

- Probe arms with magnetic coupling for fast and easy probe arm change over

- All contour probe arms equipped with an RFID chip for simplified calibration and automatic configuration

- Quick-change adapter QCA enables quick probe system changeover with minimum retooling time and automatic configuration feature

- Horizontal motion of the probe system occurs via the traverse unit enclosure, meaning the probe arm is always in front of the traverse unit

- Control panel for easy, direct operation of the most important measuring and control functions as well as emergency stop function with restart at interrupted axis position.

|

Model |

W800R |

W800C Digiscan |

W800RC Digiscan |

W800RC Surfscan |

W800RC Nanoscan |

|

Traverse unit [mm] |

120 or 200 |

120 or 200 |

120 or 200 |

120 or 200 |

120 or 200 |

|

Measuring column [mm] |

500 or 800 |

500 or 800 |

500 or 800 |

500 or 800 |

500 or 800 |

|

Granite plate [mm] |

700x520 or 1000x520 |

700x520 or 1000x520 |

700x520 or 1000x520 |

700x520 or 1000x520 |

700x520 or 1000x520 |

C. Waveline W900: Fast measuring axes for maximum precision and performance

The Waveline W900 series was developed for measuring tasks in high-performance areas, e.g. in the environment of automated process chains. The systems have two interfaces for coupling the touch probes and optionally additional axes for automating measuring sequences. The arrangement of the touch probes and the innovative traverse concept ensure optimum access to the measuring points.

W900 Stationary roughness and contour measurement meter are used especially in automated measuring sequences for particularly fast and precise results. With their measuring axes, they guarantee short measuring cycles for complex measuring tasks and thus meet the highest demands on measuring technology. The high-precision traverse unit delivers excellent measuring accuracy in conjunction with the Nanoscan touch probe for combined roughness and contour measurement.

- Fast measurement technology

- Highly flexible, dynamic measurement

- Excellent measuring accuracy in combination with Nanoscan probe system

- Extensive options for automated, CNC-controlled measurement runs

- Dual operation of two probe systems; a roughness probe system can also be installed on the front of the traverse unit; also suitable for optional rotary module

- Optional motorized tilt unit for precise adjustment of the tilt angle and automatic alignment of the probe to the workpiece level

- Measuring Z column with linear scale at a resolution of 0.1 μm for measurement of vertical distances outside the Z measuring range of the probe; requires probe arm with double probe tip

- Additional motorized Y axis or X-Y axis combination for automatic zenith search, topography measurement and workpiece positioning

- Optional rotational axis for roughness measurement on cylindrical workpieces in circumferential and axial direction.

|

Model |

W900R |

W900C Digiscan |

W900RC Digiscan |

W900RC Surfscan |

W900RC Nanoscan |

|

Traverse unit [mm] |

120 or 200 |

120 or 200 |

120 or 200 |

120 or 200 |

120 or 200 |

|

Measuring column [mm] |

500 or 800 |

500 or 800 |

500 or 800 |

500 or 800 |

500 or 800 |

|

Granite plate [mm] |

700x520 or 1000x520 |

700x520 or 1000x520 |

700x520 or 1000x520 |

700x520 or 1000x520 |

700x520 or 1000x520 |

II. Probe systems with quick-change adapter QCA

- All probe systems equipped with QCA interfaces

- Automatic setup after probe changeover

- Probe changeover without tools

- Precise, repeatable mechanical position – Hot-plug-capable

- Future-proof.

TKU400 with TAM probe arms: roughness measurement

- Universal roughness probe system

- Large measuring range

- Suitable for length and transverse measurements.

- Easily exchangeable probe arms

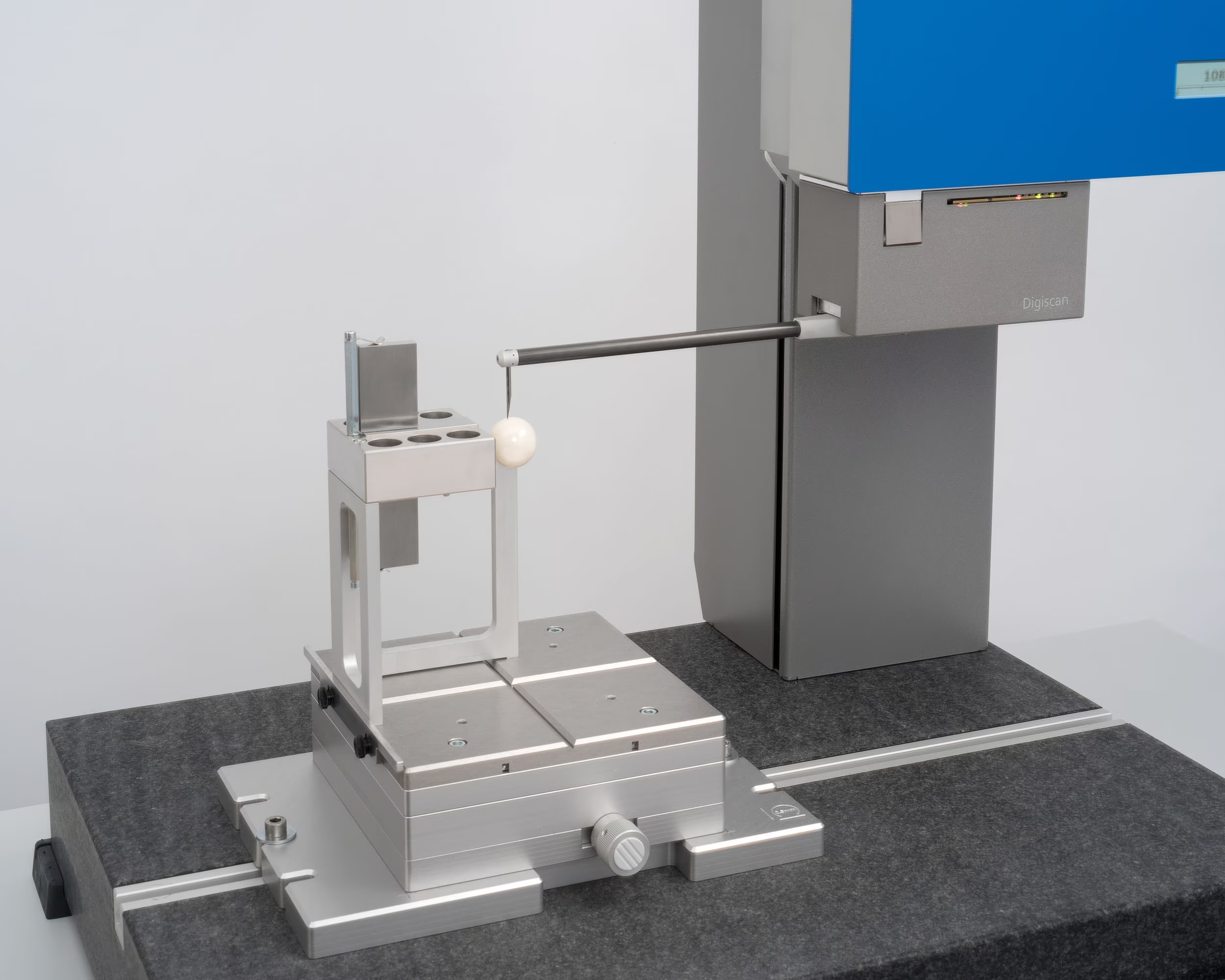

Digiscan with TD probe arms: contour measurement

- Digital measuring system with high resolution

- Optional top/bottom measurement

- Probe arms with magnetic coupling and electronic detection

- Extensive range of probe arm solutions.

Surfscan with WCN probe arms: roughness and contour measurement rolled into one

- Roughness measurement in the measuring range of 8 mm with a resolution of 3 nm

- Probe arms with magnetic coupling and electronic detection

- Optional top/bottom measurement.

Nanoscan with WCN probe arms: roughness and contour measurement rolled into one

- Ultra-precise opto-mechanical probe system

- Wide measuring range with extremely high resolution

- Excellent roughness and contour measuring accuracy in conjunction with W900.

|

Probe arm |

Measuring range | Resolution |

|||

|

Probe system |

TKU400 |

Digiscan |

Surfscan |

Nanoscan |

|

Standard length |

±400 μm | 1 nm |

60 mm | 10 nm |

8 mm | 3 nm |

24 mm | 0.3 nm |

|

2-fold length |

±800 μm | 2 nm |

90 mm | 15 nm |

16 mm | 6 nm |

48 mm | 0.6 nm |

|

Use with measuring system |

W600, W800, W900 |

W600, W800, W900 |

W800, W900 |

W800, W900 |

III. Evovis: Evaluation software for roughness and contour measurement for Stationary roughness and contour measurement meter HOMMEL ETAMIC Waveline W600 & Waveline W800 & Waveline W900

Evovis the measurement and evaluation software for roughness and contour measurement, offers a standardized user interface with easy-to-understand control logic and extensive support functions for designing individual measurement applications. Its applications range from simple measurements of a single characteristic to fully automated measurement applications within the Industry 4.0 environment.

User-friendly, intuitive operation

- Modern user interface for safe operation with little training needed

- Central control with all frequently used operating and display functions in one view

- Measuring station control with live display

- Automatic system configuration when changing the probe system or probe arm

- Extensive statistical functions

- Interactive analysis and evaluation functions

- Central administration of all test characteristics

- Evaluation of roughness parameters in the contour profile

- Roughness and contour parameters summarized in a table for further statistical evaluation.

Optimized measurement runs: CNC editor

- Fast and easy programming of automated measurement and evaluation processes with a click of the mouse

- Clear representation in a graphic workflow

- Reduction of operator influences

- Comprehensive function library.

Option CNC Professional:

- Programming of complex, automated measuring processes with axis control, electronic workpiece identification,

- Simplified user interface and automated data export.

Documented quality:

- Individual, free design of test plans as well as display and print reports

- Easy design and management of templates

- Automatic, electronic archiving of the reports.

IV. Evovis: Software functions and options for specific measurement tasks

Roughness measurement and evaluation:

- All common parameters in accordance with ISO 21920, ISO 4287 and other ISO and national standards

- Assistant for quick selection of roughness parameters and definition of the measurement conditions for safe processes and simple implementation of complex measurement tasks

- Interactive profile analysis functions for surface parameters

- Evaluation of the measurement results according to tolerance specifications with display in a compact form

- All globally standardized surface parameters for primary, roughness and waviness profiles

- Optionally expandable with function-oriented parameters.

Contour measurement and evaluation:

- Contour evaluation with assessment of geometric dimensions, tolerancing of profiles and extensive functions for the assessment of line profile deviations

- Processing of several profiles/characteristics in one test plan

- Evaluation of complex geometric elements such as Gothic arcs or edge geometries

- Icon-based features for quick test plan creation

- Realization of complex applications thanks to precise fitting procedures and various auxiliary elements.

Evaluation of several profiles in one run:

- Top/Bottom measurement

- Parallelism, angles and distance between several profiles.

Automated calibration (contour):

- Guided calibration process with recording of the history – Automatic calibration in CNC mode

- Management of the calibration means.

Options:

- qs-STAT® (Q-DAS ASCII transfer format): AQDEF- certified statistics export interface

- Dominant waviness according to VDA 2007

- TwistLive® twist evaluation in accordance with Daimler standard MBN 31 007-07 with additional quick analysis method and live display

- 3D topography evaluation.

Technical data for Stationary roughness and contour measurement meter HOMMEL ETAMIC Waveline W600 & Waveline W800 & Waveline W900

Measuring systems:

|

Model |

W600 |

W800 |

W900 |

|||||||

|

Traverse unit |

±400 μm | 1 nm |

60 mm | 10 nm |

8 mm | 3 nm |

|||||||

|

Traverse length |

120 mm |

120 mm | 200 mm |

120 mm | 200 mm |

|||||||

|

Straightness |

0.9 μm |

0.4 μm | 0.6 μm |

0.2 μm | 0.4 μm |

|||||||

|

Positioning repeatability |

<50 μm |

<50 μm |

<10 μm |

|||||||

|

X axis scale resolution |

0.1 μm |

0.1 μm |

0.01 μm |

|||||||

|

Max. positioning speed |

20 mm/s |

20 mm/s |

200 mm/s |

|||||||

|

Max. basic disturbance Rz (0.2 mm/s) |

<60 nm |

<50 nm |

<30 nm |

|||||||

|

Number of probe system interfaces |

1, bottom |

1, bottom |

2, bottom & front |

|||||||

|

Measuring column |

Zpos 300M |

Zmove 500 | Zmove 800 |

Zmove 500 | Zmove 800 |

|||||||

|

Vertical travel |

300 mm |

500 mm | 800 mm |

500 mm | 800 mm |

|||||||

|

Positioning repeatability |

– |

<50 μm |

<10 μm |

|||||||

|

Max. positioning speed |

– |

20 mm/s |

80 mm/s |

|||||||

|

Scale resolution |

– |

– |

0.1 μm |

|||||||

|

Vertical distance measurement |

– |

– |

absolute angle, inner/outer diameter |

|||||||

|

Tilt unit |

||||||||||

|

Tilt range1) |

– |

± 45° |

± 45° |

|||||||

|

Fine adjustment (optional) |

– |

± 5° |

± 5° |

|||||||

|

Probe system accuracy |

TKU400 |

Digiscan |

TKU400 |

Digiscan |

Surfscan |

Nanoscan |

TKU400 |

Digiscan |

Surfscan |

Nanoscan |

|

Rz min. tolerance cg/cgk ≥ 1.33 |

1.2 μm |

– |

0.8 μm |

– |

0.8 μm |

0.5 μm |

0.5 μm |

– |

0.5 μm |

0.15 μm |

|

Radius measurement R = 15 mm |

– |

±7 μm |

– |

±5 μm |

±5 μm |

±3 μm |

– |

±3 μm |

±3 μm |

±1 μm |

|

Radius form deviation |

– |

5 μm |

– |

3 μm |

3 μm |

1.5 μm |

– |

1.5 μm |

1.5 μm |

0.8 μm |

Probe systems:

|

Probe system |

TKU400 |

Digiscan |

Surfscan |

Nanoscan |

|

Measurement of |

roughness |

contour |

roughness & contour |

roughness & contour |

|

Measuring range/resolution (Standard probe arm length) |

± 400 μm/1 nm2) |

60 mm/10 nm2) |

8 mm / 3 nm2) |

24 mm/0.3 nm2) |

|

Measuring range/resolution (1.5x probe arm length) |

± 600 μm/1.5 nm2) |

90 mm/15 nm2) |

– |

– |

|

Measuring range/resolution (2x probe arm length) |

± 800 μm/2 nm2) |

– |

16 mm/6 nm2) |

48 mm/0.6 nm2) |

|

Top/bottom measurement |

no |

optional |

optional |

yes |

|

Measuring principle |

analog |

digital |

digital |

digital |

|

Probe identification |

yes |

yes |

yes |

yes |

|

Probe force setting |

fixed |

electronic |

electronic |

electronic |

|

Probe arm identification |

no |

yes |

yes |

yes |

|

Probe arm interface |

magnetic |

magnetic |

magnetic |

magnetic |

System configurations:

|

System configuration |

Description |

|

W600R | W800R | W900R |

roughness measuring station with TKU400 probe system |

|

W600C | W800C Digiscan | W900C Digiscan |

contour measuring station with Digiscan probe system |

|

W800RC TKU | W900RC TKU |

roughness and contour measuring station with TKU400 probe system |

|

W600RC Digiscan | W800RC Digiscan | W900RC Digiscan |

roughness and contour measuring station with separate TKU400 and Digiscan probe systems |

|

W800RC Surfscan | W900RC Surfscan |

combined roughness and contour measuring station with Surfscan probe system |

|

W800RC Nanoscan | W900RC Nanoscan |

combined roughness and contour measuring station with Nanoscan probe system |

|

Optional for all system configurations |

traverse unit 120 mm or 200 mm |

No comments yet

SIGN UP FOR A CONSULTATION

Please fill in the form below and send your comments and questions to GMGA, we will respond to your email as soon as possible.

COMMIT

100% new product

COMMIT

100% refund if the product is of bad quality and not as promised

DELIVERY

Nationwide

Review Stationary roughness and contour measurement meter HOMMEL ETAMIC Waveline W600 & Waveline W800 & Waveline W900

There are no reviews yet.