Product

Categories

- Measuring Equipment

- Vibration meter

- Force measuring equipment

- LCR Meter

- Versatile measuring equipment

- Temperature measuring equipment

- Electrical measuring equipment

- Roughness measuring meter

- Refractometer

- Viscosity meter and rheometer

- Magnetic field measuring equipment

- Microscope

- Roundness measuring equipment

- Contour measuring equipment

- Gas measuring equipment

- Diagonal and straight line laser

- Humidity measuring equipment

- Climate measuring equipment

- Spectrophotometer

- Light meter

- Gloss measuring equipment

- Distance measuring equipment

- Airflow measuring equipment

- COD meter

- Altimeter

- Mass measuring equipment

- DO meter

- Pressure gauge

- Hardness measuring equipment

- Flow meter

- Radiation meter

- Turbidity meter

- Length measuring equipment

- Thickness meters

- Dimension measuring equipment

- Sound and Noise measure

- Analytical Equipment

- Impedance analyzer

- Air quality analyzer

- Versatile analyzer

- Moisture analyzer equipment

- Conductivity analyzer and meter

- Roundness analyzer

- Logic analyzers

- Steel structure analysis equipment

- pH measure and analyze equipment

- Gas analysis equipment

- Mass analyzer

- Power quality analyzer

- Vibration analyzer

- Testing Equipment

- Charging test system

- Rub tester

- DC Bias current test system

- Hipot tester

- Impulse winding tester

- Transformer test

- Air permeability tester equipment

- Weight checking equipment

- Protective equipment testing equipment

- Insulation testing equipment

- Material flow index tester

- Friction testing equipment

- Headphone test fixtures

- Shrinkage testing equipment

- Cable harness tester

- Heat seal testing equipment

- Motor testing system

- Edge banding tester

- Stacking and compression testing equipment

- EV charging connection test system

- Versatile test equipment

- Vibration shaker test system

- Organic gas transmission rate test system

- Adhesion testing equipment

- Food testing equipment

- Seal leak tester

- Material mechanical property testing machine

- Tensile strength test equipment

- Water vapor permeability tester

- Apparatus for testing water vapor permeability by means of an electrolytic detection sensor

- Equipment for testing water vapor permeability by means of a moisture detection sensor

- Equipment for testing water vapor permeability by infrared detection sensor method

- Equipment for testing water vapor permeability by gravity method

- Air permeability tester

- Concrete testing equipment

- Maintenance Equipment

- Sound level calibrators

- Pulley alignment

- Parallel roll and roller alignment

- Video borescope

- Wood trunk defect testing equipment

- UV radiation equipment

- Ultrasonic weld testing equipment

- Defect detector

- ESD electrostatic simulator

- Surge generators and EMC measuring systems

- Bearing heater

- Concentric coaxial alignment equipment

- Dew point scanning equipment

- Audiometer calibration systems

- Device for leak diagnosis and tightness test

- Metal detector

- Thermal camera

- High speed camera

- Routing system

- Rebar detector

- Vibration diagnostic equipment detects defects

- Voltage detector

- Crankshaft deflection indicator

- Gas detector

- Pipeline detector

- Vulnerability detector

- Air quality monitoring equipment

- Surface wall scanner

- Mechanical calibration equipment

- Process Equipment

- Acoustic couplers & Ear simulators

- DC bias current source

- Workstation ART

- PCR thermal cycler

- Time-Lapse IVF incubator

- Biological safety cabinets

- Ultra-low temperature freezer

- Nucleic acid extraction system

- PCR cabinet

- Cell harvesting system

- Furnaces

- Bioreactors and fermenters

- Sound sources

- Fog and smoke simulation system

- Special function

- Titrator

- Environmental testing room

- Humidifiers

- Stirrer

- Shaker

- Centrifuge

- Industrial Equipment

- CAN solutions

- Contactless card readers

- Humidity sensor

- Motor

- Gear reducer

- Dehumidifying device

- Air purification equipment

- Drying equipment

- Heating equipment

- Ventilation equipment

- PCAN-USB adapter

- Polynomial vehicle interface

- Guide system

- Fingerprint card

- Products

Measuring Equipment

Showing 19–24 of 154 results

Precision LCR meter MICROTEST 6630 Series (10Hz ~ 50MHz)

Model: 6630-1/3/5/10/20/30/50

Precision LCR meter MICROTEST 6630 Series (10Hz ~ 50MHz) provides a wide frequency range of 10Hz to 50MHz for measuring the impedance characteristics of components and materials. The measured parameters include |Z| (impedance), |Y| (admittance), θ (phase angle), X (reactance), R (series/parallel resistance), G (conductance), B (susceptance), L (inductance), D (dissipation factor), Q (quality factor), DCR (DC resistance), C (capacitance), ESR (equivalent series resistance), ε (relative permittivity), and μr (relative permeability).

- Frequency range: DC, 10Hz to 1/3/5/10/20/30MHz/50MHz

- Basic accuracy up to: ±0.05%

- Automatic Level Control (ALC)

- Output impedance 25Ω/100Ω, switchable

- Support meter mode and list mode

- Ultra-high measuring speed < 3ms

- Open circuit/short circuit/load correction function

- Comparator function

- BIN classification function

- Built-in the Permeability-μr

- Built-in the Dielectric constant-εr.

Belt tension meter sonic KX-1590

Model: KX-1590

Belt tension meter sonic KX-1590 of Seiffert Industrial measures belt tension by analyzing the harmonic characteristics of a vibrating belt. This is completely different the nlike the force deflection method which involves applying force to the belt.

- Frequency range from 10 - 600 hertz

- Units of measure hertz, pounds, kilograms and newtons

Sonic belt tension meter 550C

Model: 550C

Sonic belt tension meter 550C of Gates device is compact, convenient to use and precise, to immediately determine the degree of loads and tension of your belt installations with utmost precision.

- Measuring accuracy: +/- 1%

- RoHS compatible

- Frequency ranges: 10-50 Hz, 10-1000 Hz, and 900-5000 Hz.

Raptor flaw detector

Model: Raptor

Raptor NDT Systems flaw detectors are used daily in the aerospace, automotive, composite and oil and gas industries. With an enhanced color display and the ability to drive the scanner to capture A, B and C scan data, Raptor collects more accurate results than other portable vulnerability detectors on the market. The Raptor is unique in its C-scan and 3D-scan capabilities, allowing operators to tackle the toughest applications in some of the harshest environments.

- Image A, B, C Scan

- Controllability of the scanning computer range

- Auto-probe – many probing possibilities

- Color display

- Compact, rugged and portable design.

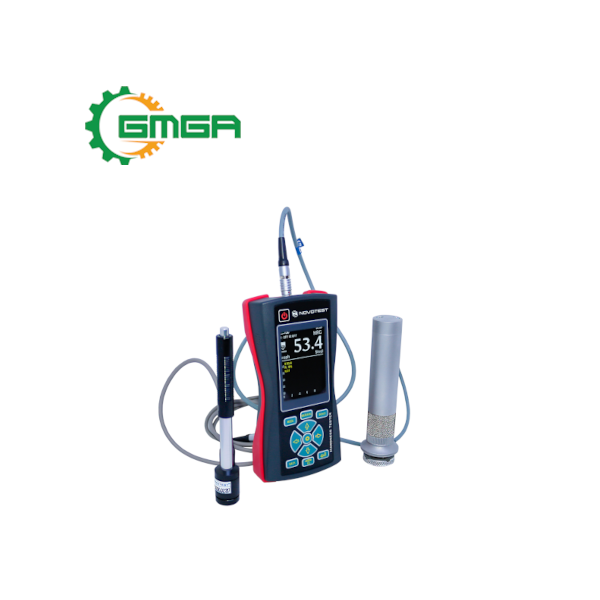

Ultrasonic and impact hardness tester NOVOTEST T-UD3

Model: T-UD3

The NOVOTEST T-UD3 Ultrasonic and Impact Hardness Tester combines two indirect methods of hardness measurement: Ultrasonic Contact Impedance (ASTM A1038) and Leeb (ASTM A956). This makes it the most versatile mobile device in the world.

The ability to connect both probes combines the advantages of both methods and provides the user with the most suitable method to solve a particular task.

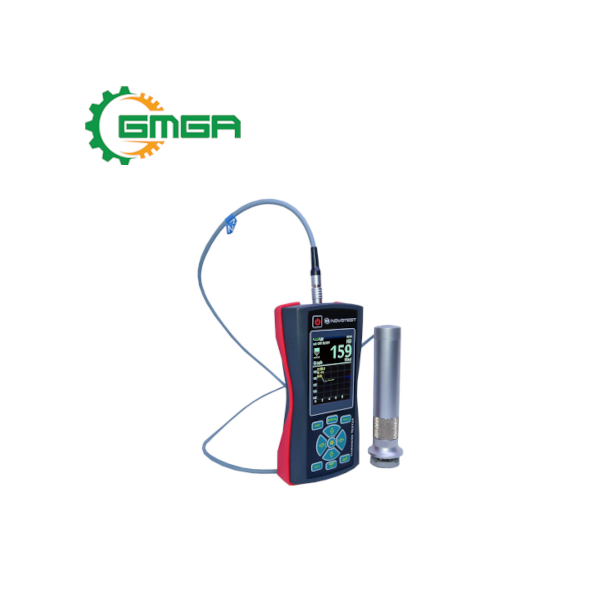

UCI hardness tester NOVOTEST T-U3

Model: T-U3

UCI hardness tester NOVOTEST T-U3 - The most popular portable hardness tester in the world is the Leeb hardness tester. However, there are tests using this method that are difficult or even impossible to solve. This is due to the physical nature of the method, which assumes the mass of the test subject, to ensure the inertness of the product when Leeb's impact body hits the surface with a certain force. To tackle a wide range of metal hardness tasks quickly, we offer hardness testers that perform the ultrasonic contact impedance (UCI) method in accordance with ASTM A1038.